Insulating Glass Units (IGU) are revolutionizing modern construction and energy conservation, combining brilliance in thermal performance, sound insulation, safety, and design flexibility. In this in-depth analysis, we'll explore the full landscape of the igu glass for sale market, crucial technical parameters, comparative manufacturer offerings, customization options, and real-world application cases.

Discover IGU Glass for Sale >>

1. Industry Overview: Demand & Trends of IGU Glass

IGU glass, commonly referred to as insulated glass units for sale, has seen unprecedented growth globally. According to a MarketsandMarkets report, the IGU market is projected to exceed $22.6 billion USD by 2027, fueled by mandatory building energy-efficient codes, advancements in smart glazing technologies, and emerging trends in sustainable construction.

Major industry drivers include stricter ISO 12543 and EN 1279 standards for performance, as well as green building certifications (LEED, BREEAM).

2. Technical Parameters: IGU Glass Units Compared

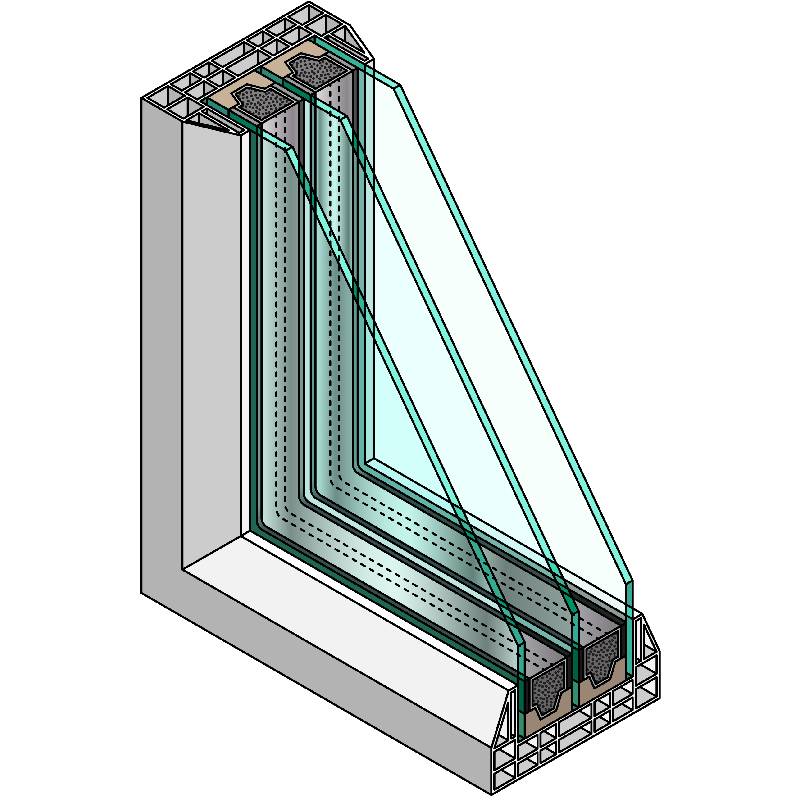

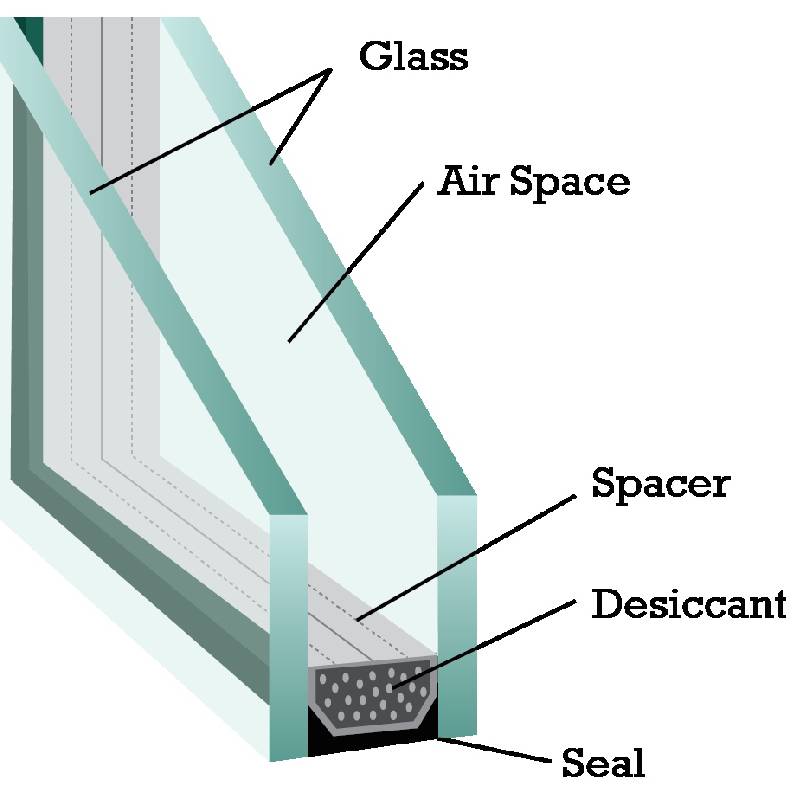

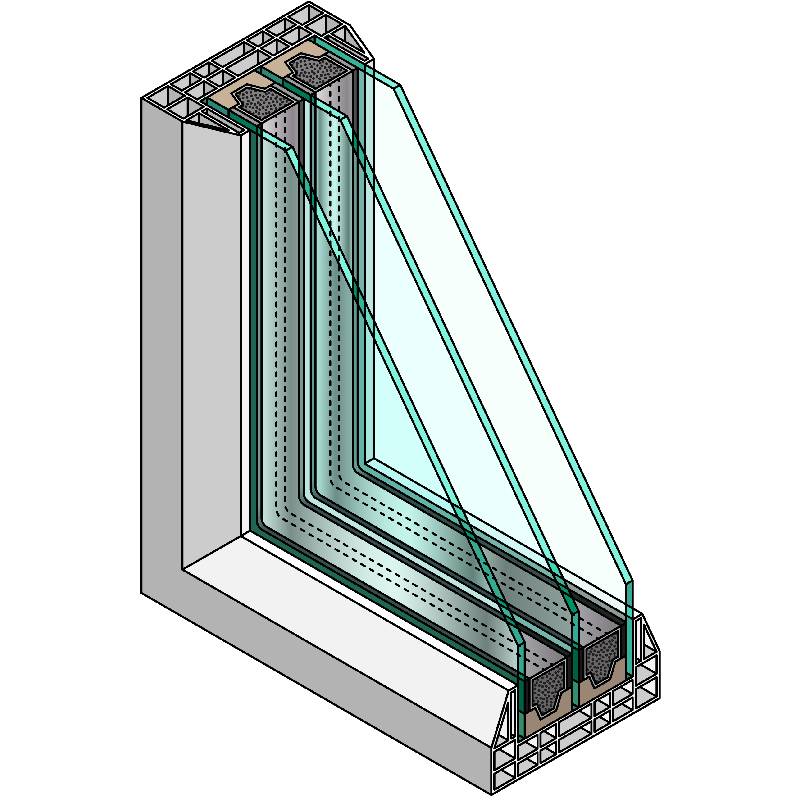

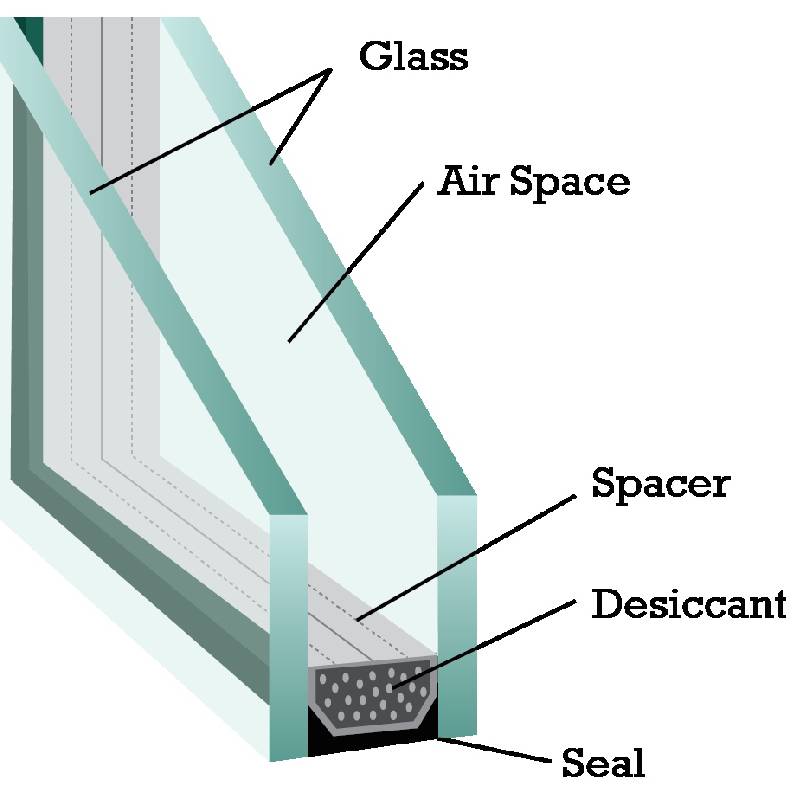

The IGU glass unit consists of at least two glass panes separated by a spacer filled with dry air or inert gas (such as argon or krypton). Typical features:

- Pane thickness: 4–12mm (per lite); customizable per specification

- Spacer width: 6–24mm

- Gas fill: Air / Argon / Krypton

- Sealant: Polyisobutylene (PIB) primary + polysulfide or silicone secondary

- Low-E coating: Optional, reduces heat gain

- Thermal transmittance (U-value): Down to 1.0 W/(m²·K)

- Sound insulation (Rw): 32–46 dB (EN 12758)

- Light transmittance: 65–80% depending on glass type

- Compliance: ISO 614, ANSI Z97.1, ASTM E2190

Chart 1: Performance comparison of IGU glass types - "Standard IGU", "Low-E IGU", "Triple-glazed IGU", and "Acoustic IGU". Lower U-value and higher Rw denote superior insulation.

3. IGU Glass for Sale Market Comparison Table

| Specification |

IGU Glass |

Insulated Glass Units for Sale |

IGU Glass Panels |

| Pane Composition |

2 or 3 panes (float/toughened/Low-E) |

2 panes (float/toughened) |

2 panes (clear/Low-E) |

| Standard Thickness |

20mm–42mm |

12mm–38mm |

16mm–40mm |

| Gas Fill |

Argon or Krypton |

Dry Air or Argon |

Argon (95% purity) |

| Compliance |

ISO 12543, EN 1279 |

EN 1279, ANSI Z97.1 |

ISO 614, ASTM E2190 |

| U-Value (W/m²·K) |

≤1.2 |

~1.7 |

≤1.4 |

| Expected Lifespan |

25–35 Years |

20–30 Years |

30 Years+ |

| Priority Industry |

Commercial, Architectural |

Residential, Public Infrastructure |

Industrial, Commercial |

4. IGU Glass Manufacturing Process (Process Flow Diagram)

Float Glass Selection

Select raw glass (float/toughened)

→

Glass Cutting & Edgework

CNC/manual cutting, edge polishing to exact sizing

→

Cleaning & Drying

Automated washing, ultrasonic drying (ISO 3545)

→

Spacer Preparation*

Filled with desiccant, cut to custom length

↓ Spacer with Desiccant & PIB Primary Sealant

Pane Assembly

Align glass with spacers, seal edges (robotic sealant, polysulfide/silicone)

→

Gas Filling

Insert argon/krypton via filling ports

→

Quality Inspection

Check for leaks, dew point, Argon retention (EN 1279-3)

→

Packing & Delivery

Protective packaging, tracking for real-time delivery status

*Spacer: Key to thermal break and condensation resistance. Materials: Aluminum, Stainless steel, or Warm-edge composite.

Main Manufacturing Processes Explored

-

CNC Glass Cutting & Edgework: CNC (Computer Numerical Control) machining delivers micron-level precision, preventing edge microcracks and improving safety.

-

Double Sealing (PIB+Polysulfide/Silicone): Ensures long-term gas retention and moisture resistance—critical for demanding climates.

-

Inspection Standards: Compliant with ISO 12543 (safety/lifetime), EN 1279 (IGU performance), and ANSI Z97.1 (impact resistance).

5. Product Specifications of Insulating Glass Unit (IGU)

| IGU Model |

Glass Configuration |

Spacer (mm) |

Gas Type |

U-Value (W/m²·K) |

Sound Insulation (dB, Rw) |

Application |

| IGU-24A-LowE |

6mm Low-E + 12A + 6mm Float |

12 |

Argon (95%) |

≤1.2 |

~36 |

Commercial Curtain Wall |

| IGU-28A-TG |

8mm Tempered + 12A + 8mm Tempered |

12 |

Argon |

1.4 |

~38 |

Industrial, Plant Windows |

| IGU-32A-TRP |

6mm+10A+6mm+10A+6mm (Triple-glazed) |

10+10 |

Air/Argon |

1.0 |

42 |

Severe Climate Zones |

| IGU-18A-HI |

5mm + 8A + 5mm Laminated |

8 |

Air |

1.7 |

~34 |

Residential |

Chart 2: Distribution of IGU glass applications. Commercial projects dominate demand, but growth in residential and severe climate sectors is accelerating.

6. IGU Glass Technology Advantages

- Energy Efficiency: Advanced igu glass panels drastically reduce HVAC costs, meeting or exceeding global “Nearly Zero Energy Building” targets.

- Thermal Insulation: State-of-the-art warm-edge spacers and triple-glazing achieve U-values down to 1.0 W/(m²·K).

- Acoustic Performance: Laminated/Acoustic IGUs provide up to 46dB noise attenuation—ideal for airports, rail stations, busy urban locations.

- Safety & Security: Tempered, laminated, or toughened panes meet ANSI Z97.1 & EN 356 standards for impact resistance.

- Condensation Resistance: Edge-sealed with argon-filled spacers, IGU units reduce cavity fogging, validated by ASTM E2190 cyclic humidity tests.

- Longevity: Exceed 25–35 years in commercial installations; 10,000+ IGUs in real cases show <2% annual seal failure rate (EN 1279-2 test).

7. Manufacturer Comparison & Supplier Evaluation

| Brand/Company |

Main Product |

Certifications |

Customization |

Warranty |

Lead Time |

| Top Glass (China) |

Insulating Glass Unit (IGU) |

ISO 12543, EN 1279 |

Thickness, Shape, Gas |

10 Years |

12–18 Days |

| Guardian Glass |

SunGuard IGU Series |

ISO 9001, EN 1279-5 |

Low-E, Spacer, Color |

5–10 Years |

15–20 Days |

| Saint-Gobain |

Climalit IGU |

ISO 14001, EN 1279 |

Glass Coating, Shape |

10–12 Years |

20–28 Days |

| Pilkington |

Optitherm IGU |

ISO 9001, CE |

Pane Count, Spacer |

8 Years |

10–16 Days |

8. Customization Solutions for IGU Glass

Every project has unique requirements. igu glass for sale options allow you to specify:

- Glass Composition: Float, tempered, laminated, or Low-E options for variable performance goals.

- Thickness: Single pane: 4mm–12mm; Overall unit: 18mm–52mm.

- Spacer Width: Optimized (6mm–22mm) to fit design & thermal needs. Warm-edge composite available.

- Custom Shapes: Square, rectangle, trapezoid, circle, and curved panels for complex facades.

- Coatings: High-Silver, Solar Control, Double/Triple Silver for enhanced solar management.

- Gas Filling: Argon (>90% purity) or Krypton for maximum efficiency.

- Integrated Blinds/Shutters: Built-in shading on request.

Customized solutions are especially valuable for façade consultants, industrial architects, and EPC contractors seeking performance certification or challenging geometries.

Chart 3: Global insulated glass unit (IGU) production growth: Market expands steadily (2018–2023, Source: Statista 2024).

9. Key Application Scenarios & Real-World Use Cases

Case Study 1: Petrochemical Facility Upgrade (China, 2022)

Challenge: High thermal loss, dust, and corrosion impacting control room windows.

Solution: Triple-glazed igu glass panels (8mm tempered + 12A + 8mm Low-E + 12A + 8mm laminated) replaced old units; cavity filled with 95% argon.

Results:

- U-value reduced from 2.5 to 1.00 W/(m²·K)

- Sound insulation improved by 9dB (measured Rw now 43dB)

- Window service life certified at >30 years as per EN 1279

Case Study 2: Urban High-rise Residential Towers (US, 2023)

Installed: Custom-shaped igu glass unit with double silver Low-E, 16mm warm-edge spacers.

Feedback: Noise complaints dropped by 71%, and heating/cooling costs declined by an average of 19% per household (data: project energy monitoring system).

Case Study 3: Metro Station Glazing (Europe, 2021)

Solution: 18mm toughened + 16A + 8mm laminated glass IGUs for improved security and antifogging in high-traffic passenger areas.

After 24 months: No visible condensation or gas leakage detected. Operator notes reduced maintenance costs.

10. Lead Time, Warranty & Quality Assurance

- Standard Delivery: 12–18 days from drawing confirmation, depending on quantity & specification.

- Warranty: 10 years for manufacturing defects, edge seal failure, gas leakage (see full conditions at IGU warranty policy).

- Certifications: Fully compliant with ISO 12543, EN 1279, ANSI Z97.1. Factory regularly audited by SGS and TUV Rheinland.

- Customer Support: 24/7 technical support, on-site installation guidance, and annual inspection programs available for commercial projects.

- Batch Testing: Random batch testing of argon fill, dew point, U-value, and seal integrity as per ASTM E2188/2190 standards.

11. FAQs: Professional IGU Glass FAQ

Q1: What is the difference between Low-E coated and standard IGU glass?

Low-E (low-emissivity) coated IGU glass features an ultra-thin metallic film that reflects infrared heat while allowing visible light to pass, substantially improving thermal insulation (U-value drop of 30–50%). Standard IGU glass does not include this coating.

Q2: Which standards should I look for in igu glass for sale?

Look for compliance with ISO 12543 (safety/lifetime), EN 1279 (insulation/durability), and ANSI Z97.1 (impact resistance). These standards guarantee reliable performance in real-world conditions.

Q3: What are typical IGU glass unit thickness combinations?

Popular options are 4+12A+4mm, 6+12A+6mm, or custom triple-pane build-ups (e.g. 5+8A+5+8A+5mm), according to project size and insulation requirements.

Q4: How does argon/krypton filling improve IGU performance?

Inert gases (argon/krypton) have lower thermal conductivity than air, reducing thermal transfer between panes and improving U-value by up to 20–30% compared to air-filled IGUs.

Q5: What is the expected service life of an IGU glass unit?

High-quality IGUs can last 25–35 years with failure rates below 2% annually, especially when manufactured and installed per ISO/EN/ANSI protocols.

Q6: Can IGU glass panels be cut to custom shapes?

Yes, CNC processing allows production of square, round, trapezoidal, curved, or even complex geometric shapes tailored to architectural requirements.

Q7: What after-sales technical support is available?

Support includes technical consultation, on-site installation training, warranty management, and periodic quality audits to maximize service life.

- Submit your project requirements or architectural drawings to the supplier.

- Get professional advice and 24-hour custom design support.

- Review and approve detailed technical drawings/specs.

- Manufacturing, on-going batch quality testing and SGS/TUV inspection.

- Delivery with full tracking, video/photo proof of quality on request.

Contact Us for IGU Glass for Sale Quotation

References & Industry Resources