The Significance of Slumping Float Glass in Modern Manufacturing

Slumping float glass has emerged as a significant innovation in the glass industry, allowing manufacturers to create a variety of shapes and forms that meet modern design and architectural demands. This versatile material combines the traditional properties of float glass with the ability to adapt to different molds and applications, thereby enhancing its utility across various sectors, including construction, automotive, and art.

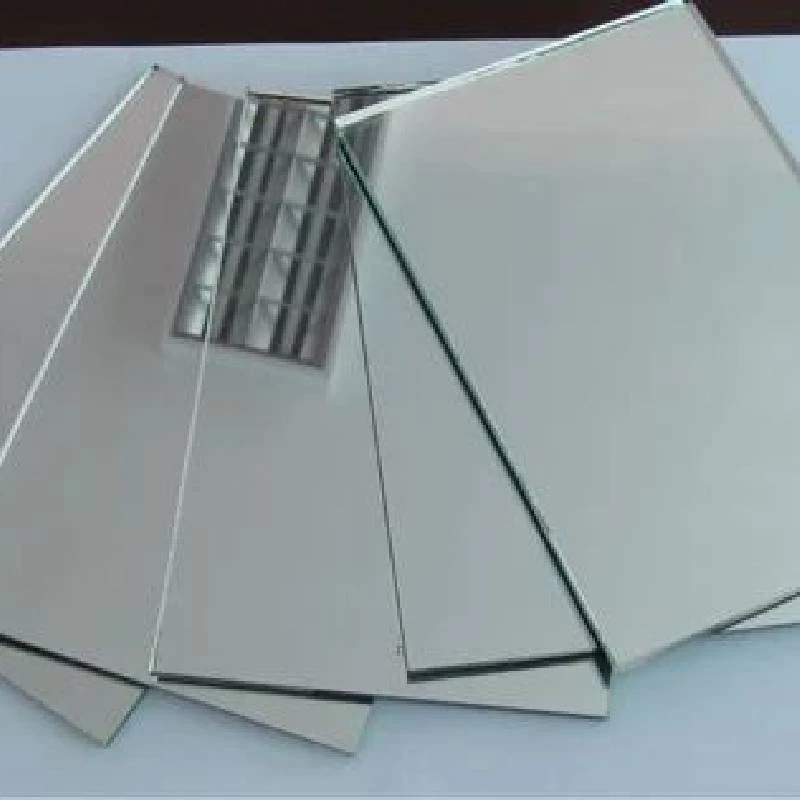

Float glass, known for its smooth surface and optical clarity, is produced by floating molten glass on top of molten tin. This process results in a flat, uniform material that is widely used in windows, facades, and other applications. However, its rigidity and flatness can be limitations in applications requiring curvature or dimension beyond two-dimensional planes. That's where slumping comes into play.

Slumping is a process that involves heating glass to a temperature just below its softening point, after which it is draped over or pressed into a mold. This technique allows the glass to take on the shape of the mold, resulting in beautifully contoured designs that would be impossible to achieve with standard float glass alone. The ability to create curved shapes not only expands aesthetic possibilities but also enhances the functionality of glass in architectural and design applications.

One of the major advantages of slumping float glass is its adaptability. Architects and designers are increasingly seeking innovative ways to create stunning visual impacts in their projects. Slumped glass can be found in diverse applications, from elegant decorative glass panels in residential spaces to striking features in commercial buildings. Its versatility enables designers to break free from conventional flat surfaces, leading to more creative and organic forms in their work.

In addition to artistic applications, slumping float glass plays a vital role in the automotive industry

. Curved glass components are essential for vehicle designs, enabling aerodynamics and enhancing aesthetic appeal. The ability to slump glass means that manufacturers can produce windshields, sunroofs, and even side windows that conform to specific design parameters, improving both the look and functionality of automotive products.Sustainability is another key consideration in modern manufacturing processes, and slumping float glass is no exception. By utilizing the existing float glass manufacturing infrastructure and transforming it through slumping techniques, manufacturers can minimize waste and make better use of materials. This is particularly important in an era where environmental responsibility is becoming a focal point across industries. The production of slumped glass can also be optimized for energy efficiency, further reducing its ecological footprint.

Despite its many advantages, there are challenges associated with the slumping process. Achieving the desired form requires precise temperature control and careful handling of glass, as improper techniques can lead to defects or cracks. Additionally, while slumped glass can be visually striking, it may require more extensive finishing work compared to standard float glass products. This increases lead times and costs, which manufacturers must account for in their planning and execution.

Nonetheless, the unique benefits of slumping float glass make it an invaluable material for today’s designers and manufacturers. As technology continues to evolve, new methods and innovations in glass manufacturing are likely to emerge, further enhancing the capabilities of slumped glass. The combination of beauty, adaptability, and sustainability ensures that slumping float glass will remain a critical component of the glass industry, enabling creative expression and functional design for years to come.

In conclusion, the significance of slumping float glass lies in its ability to transform a traditional material into something extraordinary. By allowing glass to bend, curve, and adapt to unique forms, this technique is reshaping architectural and artistic landscapes. As the industry continues to innovate, we can expect to see even more exciting possibilities for slumped glass, affirming its place as a key player in modern manufacturing.