Ultra clear glass (also known as ultra clear float glass, extra clear float glass, or low iron ultra clear glass) is revolutionizing industries demanding maximum transparency, superior aesthetics, and reliable structural performance. This comprehensive guide explores cutting-edge ultra clear glass manufacturing, technical parameters, real-world applications, industry certification, and future market trends.

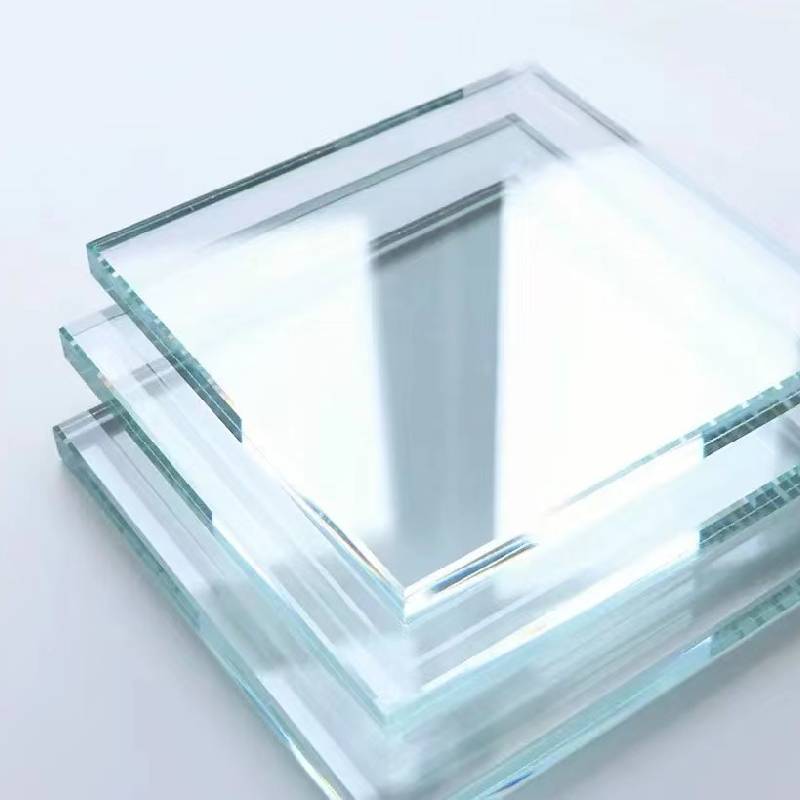

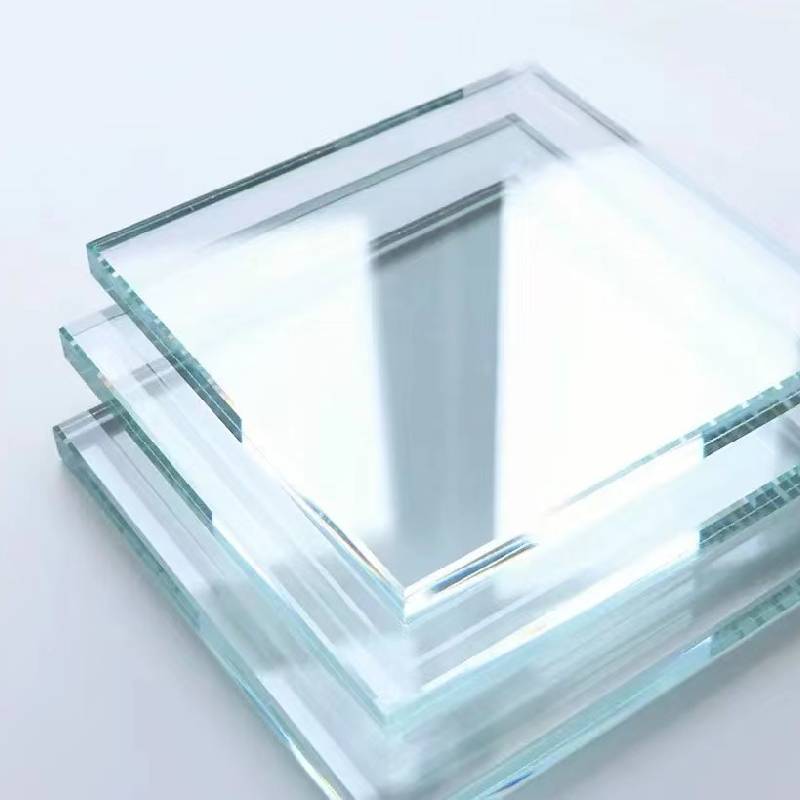

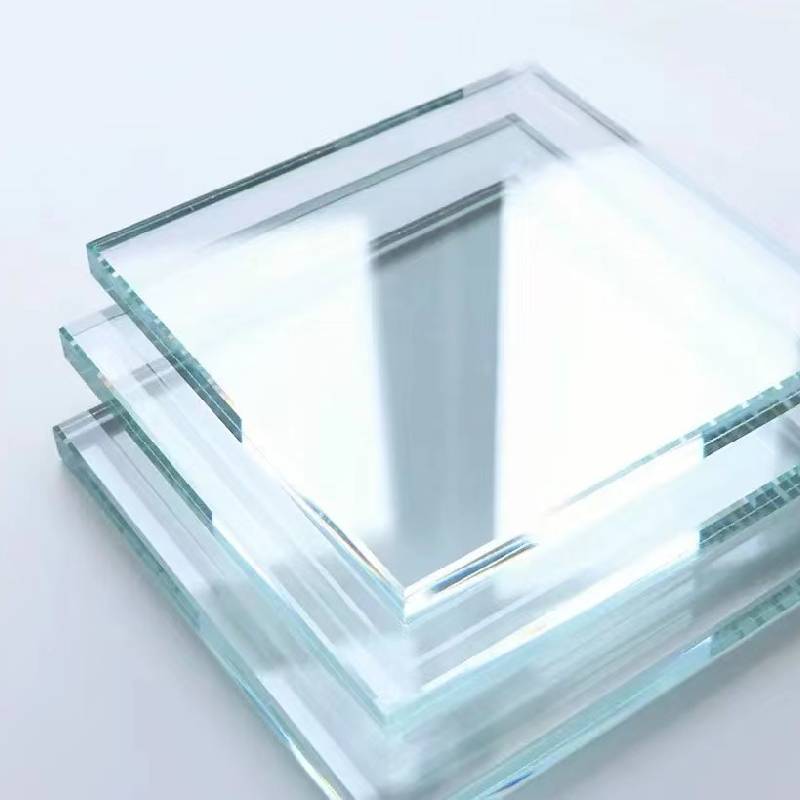

Above: High-transparency, ultra clear glass product

1. What Is Ultra Clear Glass?

Ultra clear glass is a high-light-transmission glass made with ultra-low iron content (~0.01% Fe2O3), achieving visible light transmittance above 91%. Unlike traditional float glass, it is virtually colorless even in thick sections.

- Main Synonyms: Ultra clear float glass, extra clear float glass, low-iron ultra clear glass, ultra clear tempered glass, ultra transparent glass.

- Industry Segments: Photovoltaics, architecture, display screens, high-end automotive, optics, marine windows, specialty furniture, laboratory/medical use.

2. Industry Market Trends and Outlook (2024–2027)

Global ultra clear glass market size (2023): $8.74 billion.

Forecast CAGR 2024–2027: 8.7%

Key drivers: rapid solar industry expansion, green buildings, demand for ultra-transparent facades, stricter safety and energy codes.

Major Producers: TPTOP Glass, AGC Glass, Saint-Gobain, NSG, Xinyi Glass.

Top Markets: China, US, EU, Middle East.

3. Ultra Clear Glass Manufacturing Process: Step-by-Step Diagram

Ultra clear glass manufacturing prioritizes low iron content, optical defect removal, highly controlled float lines, and state-of-the-art tempering for enhanced resistance.

- Raw materials input: Ultra-low-iron sand, limestone, dolomite, and precision color adjusters blend (Fe2O3 <0.015%).

- Melting: Batch melted at 1550–1600°C in advanced float glass furnaces.

- Float formation: Molten glass floats on molten tin, creating flawless, ultra-flat substrate.

- Annealing: Controlled cooling reduces internal stress/optical warping.

- CNC Cutting/Edging: Automated trimming, CNC-milled edge finishes (polished, arris, beveled); optional laser engraving.

- Surface Treatment: Tempering (950–670°C), chemical strengthening, or AR/Self-cleaning coating as needed.

- Quality Control: Each pane is ASTM C1036–16, EN 572-2, ISO 614 standards tested for clarity, thickness, flatness, impact.

- Packing & Shipping: Vacuum wrapping, moisture-resistant wooden crates.

4. Technical Parameters: Industry Benchmark Table

| Parameter |

Ultra Clear Glass |

Standard Float Glass |

Ultra Clear Tempered Glass |

| Iron Content (Fe2O3) |

<0.015% |

0.09–0.13% |

<0.015% |

| Light Transmittance (Tvis, 6mm) |

91.5–92.1% |

84–86% |

90.8–91.8% |

| G Value (Solar) |

0.83–0.89 |

0.78–0.82 |

0.82–0.87 |

| Thickness range |

3–25 mm |

3–25 mm |

4–19 mm |

| Color Appearance |

True colorless |

Greenish tint |

Crystal clear |

| Bending Strength |

≥120 MPa |

60–80 MPa |

≥180 MPa |

| Surface Flatness |

<0.2mm/m |

<0.5mm/m |

<0.2mm/m |

5. Application Scenarios: Where Ultra Clear Glass Excels

- Large Architectural Façades: Skyscrapers, museums, luxury residences—true daylight, no greenish cast.

- Solar PV Panels/Greenhouses: Maximized solar gain boosts module output 2-4% [SolarPowerWorld 2019].

- Display Technology: Touch panels, OLED/LED screens, anti-glare showcases, interactive kiosks.

- Automotive: Show cars, high-end sunroofs and HUDs for clear view and improved cabin ambiance.

- Chemical Plants/Marine: Superior corrosion resistance over standard glass, crucial in ship windows, laboratory apparatus.

- Designer Furniture: Aquariums, tables, balustrades—luxurious, distortion-free edge.

Case: 2023 Headquarters Curtain Wall Project (Shanghai)

Specification: 18mm

ultra clear tempered glass, 3200x4100mm panels, U-value: 1.4 W/m²K

Result: Daylight increase +13%, cooling costs reduced ~6%, no visible greenish edge, client:

SOM Pudong Tower.

6. Technical Advantages & Certifications

-

Clarity: True colorless appearance enables best viewing, displays, luxury real estate, and artworks.

-

Strength: Up to 180 MPa after tempering—complies with ANSI Z97.1, EN12150, ISO 614 impact and safety glazing standards.

-

Surface Quality: Scratch-resistant, low distortion (flatness <0.2 mm/m, ISO 9050-certified).

-

Longevity: 20–30 years structural life (with proper edge protection).

-

Environmental: Can be recycled to over 96%, RoHS/REACH compliant (no hazardous metals).

Accredited Factory Certifications: ISO9001; CE Mark (EN 12150, EN 14449); SGS-approved; Test Reports available on request.

7. Major Manufacturers Comparison

| Manufacturer |

Product Brand |

Max Size (mm) |

Transmittance (%) |

Certifications |

Key Features |

| TPTOP Glass |

Ultra Clear® |

3300 x 6100 |

91.8 |

ISO, EN12150, SGS |

Thick panels, edgework, OEM coating |

| AGC |

Clearsight™, Planibel Clearsight |

3210 x 6000 |

91.5–91.9 |

ISO, CE, EN |

Anti-reflective, UV options |

| Saint-Gobain |

Diamant® |

3210 x 6000 |

91.5 |

ISO, EN, ASTM |

Consistent batches |

| NSG Pilkington |

Optiwhite® |

3210 x 6000 |

91.7 |

ISO, EN |

Solar and structural grades |

| Xinyi Glass |

Extra Clear XT |

3300 x 6000 |

91.4 |

ISO, SGS |

Low cost, wide thickness |

8. Custom Solutions & Processing

-

Dimension: Max 3300 x 6100mm, min 160 x 260mm; cut-to-size and irregular shapes available.

-

Thickness: 3–25mm, common: 4, 6, 8, 10, 12, 15, 19mm.

-

Edgework: Flat, pencil, beveled, CNC-polished, mitre cut.

-

Surface: Sandblasted, anti-reflective (AR), coated (self-cleaning, hydrophobic), silk screen, digital print.

-

Laminated Panels: PVB, SGP, EVA interlayers for safety/security, acoustic damping.

-

Insulating Glass Units: IGU with triple/quadruple glaze; argon/krypton-filled, warm-edge spacer options.

9. Project Case Studies / Customer Experience

Client: Abu Dhabi Presidential Palace Dome (2022)

Challenge: High humidity, salt corrosion, color consistency in domed skylights.

Solution: 17.52mm

low iron ultra clear glass IGU, triple laminate, AR-coated.

Outcome: No discoloration after 18 months, routine cleaning cycle reduced by 24%, praised by German certifiers (

ift Rosenheim).

Luxury Retail (US Flagship): Replaced 12mm standard float with ultra clear tempered glass; net footfall increased by 9.5% after renovation, peak sales periods observe up to 18% more sunlight penetration.

10. Delivery, Warranty & Customer Support

- Delivery lead time: 7–21 business days (ex-works), depending on order size/spec.

- Global pack/shipping: Compliant with ASTM C1036-16 export crate standards.

- Warranty: 10 years optical/corrosion, 5 years edge seal, full traceability.

- Technical support: Pre-sale design, on-site installation training, 24x7 remote assistance.

- Samples: 300x300mm sample available within 5 days on request.

- After-sales: On-site inspection (Asia/EU/ME), regular performance audits.

11. FAQ: Ultra Clear Glass Technical FAQ

-

Q1: What is the iron content in ultra clear glass and why important?

A1: Fe2O3 content is less than 0.015%, dramatically lowering the absorption of visible light and eliminating the greenish tint common to standard float glass.

-

Q2: What standard thicknesses and sizes are commonly stocked?

A2: Thickness: 4, 6, 8, 10, 12, 15, 19 mm; Maximum single pane: 3300x6100mm; custom and shaped cuts on demand.

-

Q3: How does ultra clear float glass differ from tempered glass?

A3: “Float” refers to the manufacturing method (molten glass “floats” on tin bath); “tempered” means heat-strengthened for impact and thermal resistance. Ultra clear float glass can be further tempered.

-

Q4: Which international standards does this product meet?

A4: Complies with ISO 614, EN 572-2 (Europe), ASTM C1036 (USA), ANSI Z97.1 (Safety Glazing), RoHS/REACH (environmental).

-

Q5: Is ultra clear glass suitable for double/triple glazing?

A5: Absolutely. It is widely used in insulating glass units (IGU), often with solar control, self-cleaning, or low-E coatings.

-

Q6: What about edge finishes and CNC processing?

A6: Custom edge profiles (flat, arris, pencil-polish, beveled), CNC engraving, holes and notches are easily manufactured to millimeter precision.

-

Q7: Does ultra clear glass require special installation?

A7: Use standard structural framing; ensure compatible sealants (silicone neutral-cure) to avoid staining. Larger panes (>3m) require specialist handling to prevent breakage and preserve warranty.

12. Further Reading, Technical Forums & References