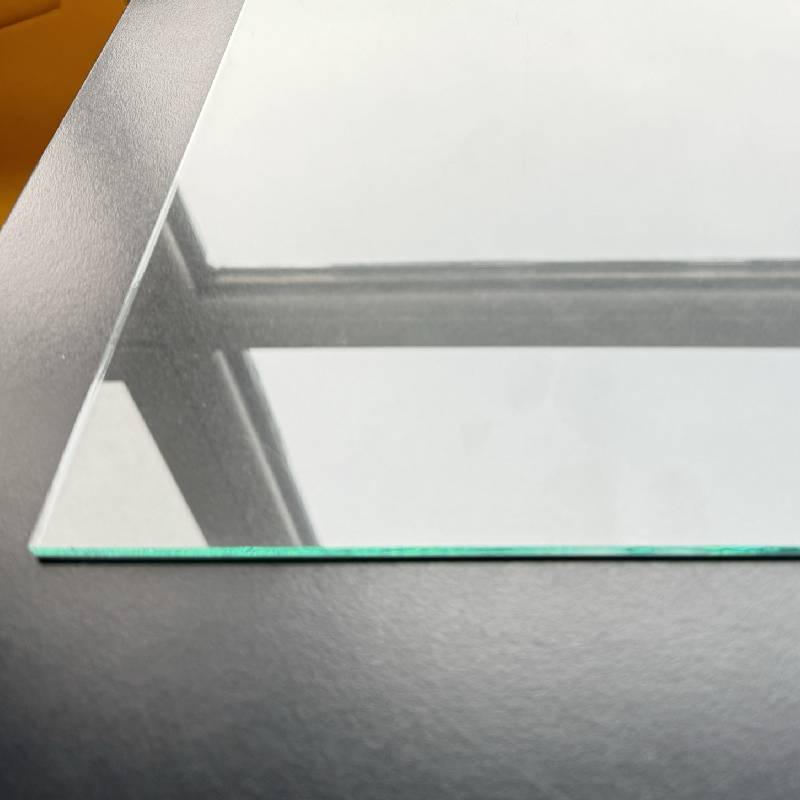

In the dynamic landscape of modern architecture, interior design, and specialized industrial applications, the demand for unparalleled visual clarity and superior light transmission has driven significant advancements in glass technology. Among these innovations, ultra clear glass stands out as a revolutionary material, setting new benchmarks for transparency and aesthetic appeal. Also known interchangeably as low iron glass or extra clear float glass, this specialized product is engineered to virtually eliminate the greenish tint inherent in standard float glass, a hue caused by the presence of iron oxides within the raw material composition. By meticulously reducing the iron content during the manufacturing process, ultra clear glass achieves an exceptional level of clarity, allowing for maximum light penetration and true color rendition. This technological leap has profound implications across various sectors, enabling designs that previously seemed impossible and enhancing the functionality of light-sensitive applications. The industry is currently witnessing a robust trend towards integrating high-performance materials, with ultra clear glass leading the charge due to its superior optical properties. This shift is particularly evident in sectors prioritizing aesthetic purity, energy efficiency through enhanced natural light, and the precise visual fidelity required for display technologies. The market's embrace of products like ultra clear float glass, ultra clear tempered glass, and ultra clear shower glass underscores a collective move towards materials that not only perform exceptionally but also contribute to the overall environmental performance and design integrity of projects. As sustainability and visual excellence continue to be paramount, the unique attributes of low iron ultra clear glass position it as a cornerstone material for future innovations.

The production of ultra clear glass is a testament to advanced material science and stringent quality control, fundamentally rooted in the sophisticated float glass process but with critical modifications. This specialized manufacturing begins with the selection of premium raw materials, primarily silica sand with an exceptionally low iron oxide content, typically less than 0.01%. This contrasts sharply with standard float glass, which uses sand containing up to 0.1% iron, responsible for the characteristic green tint. The carefully measured blend of low-iron silica sand, soda ash, limestone, and other minor components is meticulously melted in a furnace at extremely high temperatures, often exceeding 1600°C. This molten glass then flows onto a bath of molten tin, a process known as 'floating,' where the glass spreads evenly and achieves a perfectly flat, parallel surface due to the laws of gravity and surface tension. The controlled cooling, or annealing, within a lehr gradually reduces the glass temperature, eliminating internal stresses and enhancing its strength and optical quality. The crucial difference for extra clear float glass lies in the purity of the initial melt and the precise temperature profiles maintained throughout the float line to preserve the low-iron properties. Once cooled, the continuous ribbon of glass is cut into various sizes and further processed for specific applications, such as tempering or laminating, to meet safety and performance requirements. Inspection standards, such as ISO 9001 for quality management and ASTM (American Society for Testing and Materials) standards for specific glass properties (e.g., ASTM C1036 for flat glass), are rigorously applied throughout the process, from raw material inspection to final product verification, ensuring consistent clarity, dimensional accuracy, and structural integrity. The use of advanced inspection equipment, including spectral photometers and optical distortion analyzers, ensures that each pane of low iron ultra clear glass meets the highest industry benchmarks, offering an expected service life that matches or exceeds traditional glass products, often decades, depending on environmental conditions and application.

Understanding the technical specifications of ultra clear glass is crucial for architects, designers, and engineers looking to leverage its full potential. The defining characteristic is its superior light transmission, which typically ranges from 91% to 92% for a 3mm thickness, significantly higher than the 88-89% offered by standard float glass of the same thickness. This elevated transparency is a direct result of the reduced iron content, minimizing absorption and maximizing the amount of visible light passing through. Another critical parameter is the color rendering index (CRI) or color accuracy; low iron ultra clear glass ensures that colors viewed through it appear truer to their natural state, without the greenish cast that can distort perception. Its low energy absorption properties also contribute to reduced heat build-up in sun-exposed applications, potentially aiding in energy efficiency. Mechanically, when processed into ultra clear tempered glass, it offers four to five times the strength of annealed glass of the same thickness, making it highly resistant to impact and thermal stress. The uniform density, typically around 2500 kg/m³, ensures consistent structural performance. Furthermore, its excellent surface flatness and optical clarity make it ideal for applications requiring precise visual quality, such as display screens or high-end architectural glazing. The table below provides a concise overview of typical parameters, showcasing the distinct advantages of this advanced material. These specifications are not merely numbers; they represent the tangible benefits of enhanced aesthetics, improved energy performance, and superior optical fidelity that ultra clear float glass brings to diverse projects. Adherence to these parameters, verified through rigorous testing, is what differentiates a premium product capable of meeting the demands of sophisticated modern applications.

| Parameter | Ultra Clear Glass (Low Iron) | Standard Float Glass | Units |

|---|---|---|---|

| Visible Light Transmittance (3mm) | > 91.5% | ~ 89% | % |

| Iron Content (Fe2O3) | < 0.01% | ~ 0.1% | % |

| Solar Energy Transmittance (3mm) | > 90% | ~ 87% | % |

| Solar Direct Reflectance (3mm) | ~ 8% | ~ 8% | % |

| Density | ~ 2500 | ~ 2500 | kg/m³ |

| UV Transmittance (3mm) | ~ 75-80% | ~ 60-65% | % |

The technical advantages of ultra clear glass extend far beyond mere aesthetics, delivering tangible benefits across a spectrum of demanding applications. Its primary and most compelling advantage is its exceptionally high visible light transmittance, which allows more natural light to penetrate spaces. This not only creates brighter, more inviting interiors but also contributes significantly to energy savings by reducing the reliance on artificial lighting during daylight hours. Furthermore, the true color fidelity offered by extra clear float glass means that objects viewed through it retain their authentic colors without distortion, a critical factor in art galleries, retail displays, and museum showcases where accurate color representation is paramount. Unlike standard glass, which imparts a subtle green tint, especially noticeable on thicker panels or along edges, low iron ultra clear glass maintains a neutral appearance, making it the preferred choice for applications demanding visual purity, such as frameless glass partitions, balustrades, and high-end furniture. In solar energy applications, the high solar energy transmittance of ultra clear float glass directly translates to enhanced efficiency for photovoltaic (PV) panels and solar thermal collectors, maximizing energy capture and yield. Its improved UV transmittance compared to standard glass can also be an advantage for certain horticultural or specialized lighting applications, though it can also be tempered to control UV for preservation purposes. When transformed into ultra clear tempered glass, it combines its optical excellence with superior mechanical strength and safety features, shattering into small, blunt pieces upon breakage, significantly reducing injury risk. This dual benefit of clarity and safety makes it ideal for shower enclosures, storefronts, and overhead glazing. The material’s inherent purity also contributes to a cleaner appearance that resists slight discoloration over time, ensuring the longevity of its pristine look. These cumulative technical advantages solidify the position of ultra clear glass as a premium solution for projects where performance, aesthetics, and energy efficiency converge.

The versatility of ultra clear glass allows it to be integrated into an impressive array of applications, transforming spaces and enhancing product performance across diverse industries. In the architectural sector, it is extensively used for building facades, skylights, atriums, and large window installations where maximizing natural light and offering unobstructed views are paramount. Its superior transparency lends itself perfectly to modern, minimalist designs, providing a seamless connection between indoor and outdoor environments. Interior applications also benefit immensely, with ultra clear shower glass becoming the standard for luxurious bathrooms due to its virtually invisible appearance and resistance to the greenish tint, enhancing the bathroom's overall brightness and sophistication. Similarly, frameless glass railings, partitions in commercial offices, and display cases in high-end retail stores all leverage the neutrality of extra clear float glass to highlight products and create open, airy spaces. Beyond aesthetics, the efficiency gains in the solar industry are significant; low iron ultra clear glass is the preferred choice for photovoltaic solar panels and solar thermal collectors, as its higher light transmittance directly translates to greater energy conversion efficiency and increased power output. In the realm of electronics and displays, it is utilized for touchscreens, LCD displays, and projection screens where visual clarity, minimal distortion, and accurate color reproduction are non-negotiable. Furniture manufacturers also employ ultra clear glass for tabletops, shelving, and cabinet doors, offering a premium finish that elevates design. Notable application cases include iconic buildings that utilize extensive glass facades to create striking visual statements, or large-scale solar farms where every percentage point of efficiency gain contributes to massive energy savings. Customer feedback consistently highlights satisfaction with the perceived spaciousness, enhanced natural lighting, and the overall premium feel that ultra clear glass brings to their projects. This widespread adoption across residential, commercial, and industrial sectors underscores its critical role as a high-performance material that meets and exceeds contemporary demands for clarity, efficiency, and aesthetic excellence.

The inherent versatility of ultra clear glass is significantly enhanced by the extensive customization options available, allowing it to meet the precise demands of highly specialized projects. Beyond its core attribute of low iron content, manufacturers can further process ultra clear float glass into various forms to achieve desired performance characteristics. This includes thermal tempering, which transforms it into ultra clear tempered glass, significantly increasing its impact resistance and making it a safety glass suitable for high-traffic areas, balustrades, and structural glazing. Lamination is another common customization, where multiple layers of extra clear float glass are bonded together with an interlayer (often PVB or SGP) to create laminated glass, offering enhanced security, sound insulation, and UV protection. This is particularly valuable for applications in museums, banks, or areas exposed to high noise levels. Specialized coatings can also be applied to the surface of low iron ultra clear glass to modify its properties further. These coatings can range from anti-reflective treatments for display cases and electronic screens, which minimize glare and maximize visual clarity, to low-emissivity (Low-E) coatings that improve thermal performance by reflecting infrared radiation, crucial for energy-efficient building envelopes. Furthermore, custom shapes, sizes, edge work (e.g., polished, beveled, or drilled holes), and even frit patterns or digital printing can be applied to ultra clear glass panels to integrate aesthetic design elements or functional features like privacy screens. Our company, with over 15 years of experience in the glass industry, specializes in providing bespoke solutions for B2B clients, leveraging advanced CNC processing capabilities to produce complex geometries and precise dimensions. We collaborate closely with architects and designers from conception to completion, ensuring that the chosen customization not only meets technical specifications but also aligns perfectly with the project's aesthetic vision and functional requirements. This commitment to tailor-made solutions ensures that every piece of ultra clear glass delivered is optimally suited for its intended high-performance application.

When investing in high-performance materials like ultra clear glass, trustworthiness and robust customer support are as crucial as the product's technical specifications. Our commitment to quality is underscored by comprehensive quality control measures that adhere to international standards such as ISO 9001:2015, ensuring consistency and reliability from raw material sourcing to final product delivery. We provide detailed test reports and certifications for our extra clear float glass, verifying its optical properties, mechanical strength (especially for ultra clear tempered glass), and dimensional accuracy. Understanding the critical timelines of B2B projects, we maintain efficient production schedules and a streamlined logistics network to ensure reliable delivery cycles. Our standard delivery lead times are typically 15-20 business days for custom orders, with expedited options available upon request to accommodate urgent project deadlines. Each shipment is meticulously packaged to prevent damage during transit, ensuring the pristine condition of the low iron ultra clear glass upon arrival. Furthermore, our products are backed by a comprehensive warranty, typically covering manufacturing defects for 5 to 10 years, providing peace of mind for our clients' long-term investments. Our dedicated customer support team comprises experienced technical advisors who are available to assist with product selection, installation guidance, and troubleshooting. We offer pre-sale consultations, detailed technical drawings, and post-sale support, ensuring a seamless experience for our partners. This holistic approach to client satisfaction has fostered strong, long-term relationships with architects, contractors, and developers worldwide. For common queries, our Frequently Asked Questions (FAQ) section addresses topics such as cleaning and maintenance of ultra clear shower glass, differences between various glass types, and recommendations for installation. We believe that a superior product must be matched with superior service, guaranteeing not just transparency in glass but also transparency in our business dealings, building lasting trust with every project we undertake.

The primary difference lies in the significantly lower iron oxide content in the raw materials used for ultra clear glass. This reduction eliminates the greenish tint commonly seen in standard float glass, especially noticeable on thicker panels or along the edges, resulting in superior transparency, higher light transmission, and true color rendition.

Yes, ultra clear glass is highly versatile and can be processed into ultra clear tempered glass for enhanced strength and safety, or laminated with interlayers to improve security, sound insulation, and UV protection. These processes do not diminish its inherent clarity.

Due to the specialized raw materials and more refined manufacturing process involved in reducing iron content, ultra clear glass generally has a higher cost than standard float glass. However, its superior aesthetic, optical performance, and potential for energy savings often justify the investment for high-value applications.

Its primary applications include architectural facades, skylights, interior partitions, shower enclosures (ultra clear shower glass), display cases, solar panels, and high-end furniture. It is chosen where maximum transparency, true color representation, and aesthetic purity are critical.

By allowing a higher percentage of natural light to pass through, ultra clear glass can reduce the need for artificial lighting during daylight hours, thereby lowering energy consumption. In solar applications, its high solar energy transmittance directly enhances the efficiency of solar energy capture.