In an era increasingly focused on energy efficiency and sustainable building practices, the demand for advanced glazing solutions has never been higher. Insulating Glass Units (IGUs), also commonly referred to as Double Glazing or hermetically sealed units, stand at the forefront of this revolution, offering unparalleled thermal and acoustic performance. These sophisticated assemblies comprise two or more panes of glass separated by a vacuum or gas-filled space, designed to significantly reduce heat transfer across the building envelope. As architects and developers strive for greener, more comfortable, and cost-effective structures, the market for igu glass for sale continues to expand, driven by stringent energy codes and a growing awareness of environmental impact. This robust demand underscores the critical role of high-quality IGU products in modern construction, from towering commercial facades to energy-efficient residential homes.

The industry is witnessing rapid advancements in IGU technology, including the integration of low-emissivity (Low-E) coatings, inert gas fills like argon or krypton, and advanced spacer systems, all contributing to superior thermal performance. These innovations address the need for enhanced comfort, reduced heating and cooling costs, and improved indoor environmental quality. Furthermore, the aesthetic versatility of igu glass allows for diverse architectural expressions, making it a preferred choice for projects that demand both performance and visual appeal. Understanding the intricate details of these units, from their manufacturing process to their precise technical specifications, is crucial for B2B decision-makers seeking optimal glazing solutions for their next project.

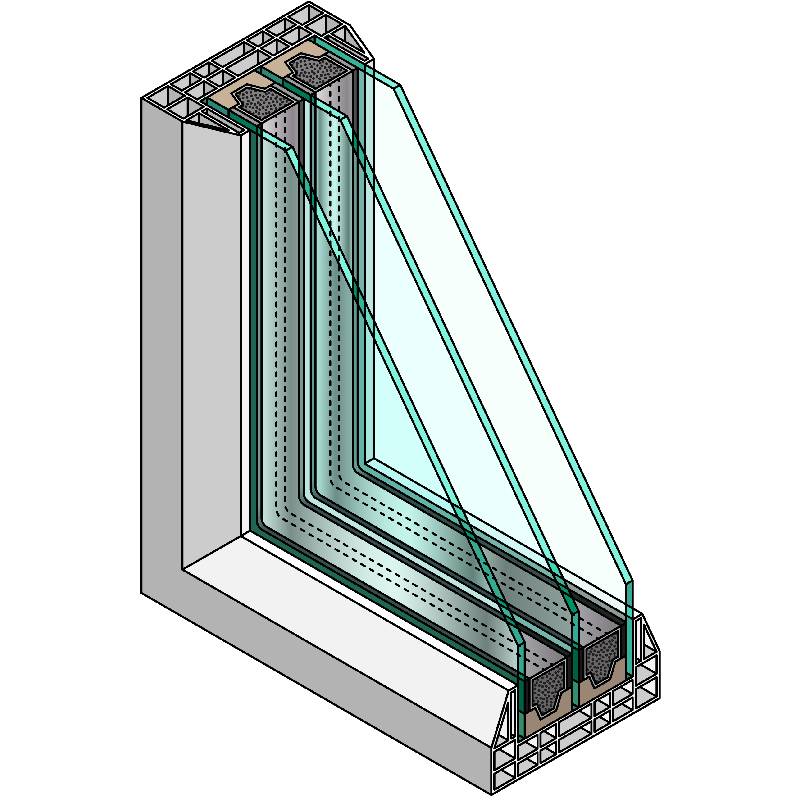

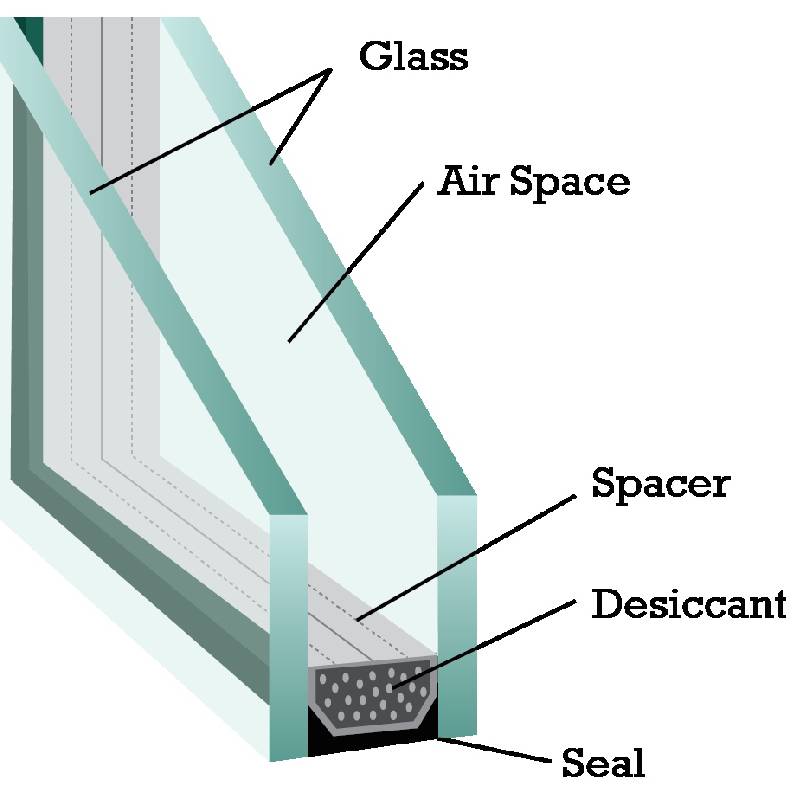

An Insulating Glass Unit, at its core, is an engineered system designed to optimize thermal and acoustic insulation. It typically consists of two or more panes of glass, such as float glass, tempered glass, or laminated glass, carefully selected based on the project's specific requirements for strength, safety, and optical properties. These panes are separated by a precisely measured space, known as the air gap, which can be filled with dehydrated air or, more commonly, an inert gas like argon or krypton. Argon, being denser than air, reduces convection within the gap, significantly improving the unit's thermal performance and contributing to a lower U-value. Krypton offers even better insulation due to its higher density but is typically used in thinner air gaps.

Key to maintaining the integrity of this gas-filled space is the spacer bar, which separates the glass panes and houses a desiccant material. The desiccant, often molecular sieve, absorbs any residual moisture from within the air gap, preventing condensation and maintaining the unit's clarity and performance over its lifespan. The entire assembly is then hermetically sealed around the perimeter using primary and secondary sealants. The primary sealant, often butyl, provides a strong initial barrier against moisture vapor transmission, while the secondary sealant, typically silicone or polysulfide, offers structural integrity and long-term durability. The combination of these components creates a sealed environment that dramatically reduces heat transfer, making igu glass panels highly effective in energy conservation strategies. The U-value, a critical performance metric, quantifies the rate of heat transfer through the unit, with lower values indicating better insulation.

The manufacturing process of igu glass is a highly automated and precise operation, crucial for ensuring the unit's long-term performance and durability. It typically begins with the accurate cutting of glass sheets to the required dimensions, often using CNC-controlled equipment for maximum precision. After cutting, the glass edges are ground and polished to prevent stress concentrations and ensure safety. A critical step is the thorough washing and drying of the glass panes to remove any contaminants that could impair optical clarity or sealant adhesion. This is usually performed using de-ionized water and specialized drying equipment in a dust-free environment.

Next, the spacer frames, often made of aluminum or more thermally efficient "warm edge" materials like stainless steel or composite polymers, are assembled and filled with desiccant. These frames are then meticulously positioned between the clean glass panes. In the case of gas-filled units, the inert gas (e.g., argon) is injected into the cavity before the final sealing process. The perimeter of the unit is then sealed, typically in two stages: a primary seal (butyl) applied directly to the spacer to block moisture and gas, and a secondary structural seal (silicone or polysulfide) for long-term adhesion and structural integrity. Throughout this entire process, strict quality control measures are implemented, adhering to international standards such as ISO 9001, ASTM E2188/E2189/E2190, and EN 1279, to ensure the hermetic seal, gas retention, and overall performance of every igu glass unit. These rigorous standards guarantee an expected service life of 20 years or more under normal conditions.

When sourcing insulated glass units for sale, understanding key technical specifications is paramount for ensuring the product meets project requirements. Performance is quantified by several critical parameters. The U-value (or U-factor) measures the rate of heat transfer, where a lower value indicates better insulation. Solar Heat Gain Coefficient (SHGC) represents the fraction of solar radiation admitted through a window, either directly transmitted or absorbed and re-radiated inward; a lower SHGC is desirable in hot climates to reduce cooling loads. Visible Light Transmittance (VLT) indicates the percentage of visible light that passes through the unit, influencing daylighting. Sound Transmission Class (STC) measures a window's ability to reduce airborne sound, crucial for noise reduction in urban environments.

| Parameter | Description | Typical Range (Standard Clear IGU) | Enhanced Performance (Low-E/Argon) |

|---|---|---|---|

| U-value (W/m²·K) | Heat transfer coefficient; lower is better. | 2.5 - 3.0 | 1.1 - 1.8 |

| Solar Heat Gain Coefficient (SHGC) | Fraction of solar heat transmitted; lower is better for cooling. | 0.70 - 0.80 | 0.20 - 0.50 |

| Visible Light Transmittance (VLT) | Percentage of visible light transmitted; higher for more daylight. | 80% - 90% | 60% - 80% (depends on Low-E type) |

| Sound Transmission Class (STC) | Reduction in sound; higher is better. | 28 - 32 | 32 - 40+ (with specific glass types/gaps) |

| Glass Thickness (mm) | Individual pane thickness. | 3mm - 12mm+ | Varies by application |

| Air Gap (mm) | Space between glass panes for insulation. | 6mm - 16mm | Optimal: 12mm-16mm for Argon |

These parameters are crucial for specifying the correct igu glass for sale to meet building codes, energy efficiency goals, and occupant comfort requirements. For instance, in colder climates, a very low U-value is prioritized, while in warmer regions, a low SHGC is more critical. The choice of glass types (e.g., clear, tinted, reflective, low-E), the type of gas fill, and the spacer material all significantly influence these performance metrics.

The adoption of Insulating Glass Units offers a multitude of advantages that extend beyond mere energy savings, making them a cornerstone of modern, high-performance buildings. Firstly, their superior thermal insulation capabilities significantly reduce heat loss in winter and heat gain in summer, leading to substantial reductions in heating and cooling energy consumption. This translates directly into lower operational costs for building owners and a smaller carbon footprint, aligning with global sustainability goals. Secondly, IGUs provide excellent acoustic insulation, dampening external noise from traffic, construction, or urban environments, thereby creating quieter and more comfortable indoor spaces, which is particularly beneficial for residential buildings, schools, and hospitals.

Furthermore, the sealed nature of igu glass units prevents interior condensation, improving indoor air quality and preventing potential mold growth, which can be a common issue with single-pane windows in humid environments. They also offer enhanced UV protection, minimizing fading of interior furnishings and artwork. From an application perspective, IGUs are incredibly versatile. They are indispensable in residential construction for windows and doors, commercial buildings for facades and curtain walls, and institutional facilities like schools and hospitals where energy efficiency and indoor comfort are paramount. Specialized applications include refrigeration units, transportation (trains, buses), and industrial settings where precise temperature control or sound dampening is required. The ability to customize glass types (e.g., laminated for security, tempered for safety, tinted for glare control) ensures that igu glass for sale solutions can be tailored to meet almost any project-specific requirement.

Choosing the right supplier for insulated glass units for sale is a critical decision that impacts a project's long-term performance and cost-efficiency. Key considerations include the manufacturer's adherence to international quality standards, their capacity for customization, and their proven track record. A reputable supplier will hold certifications such as ISO 9001 for quality management systems, demonstrating their commitment to consistent product excellence. Furthermore, they should provide detailed product data, including U-values, SHGC, and STC ratings, supported by independent testing.

Customization capabilities are vital for architectural projects with unique design or performance requirements. This includes the ability to specify various glass types (e.g., low-iron for maximum clarity, patterned for privacy, fire-rated for safety), different gas fills, spacer materials, and integrated features like blinds or electrochromic layers. A vendor experienced in manufacturing diverse igu glass panels can offer tailored solutions that precisely match specific aesthetic and functional needs. At TPTOPGLASS, our extensive experience in the B2B sector, coupled with our state-of-the-art manufacturing facilities, allows us to deliver high-quality, custom igu glass for sale solutions that meet the stringent demands of modern construction. We pride ourselves on transparent communication, reliable delivery schedules, and comprehensive technical support, ensuring that our clients receive not just a product, but a complete glazing solution backed by expertise. Our commitment to quality and customer satisfaction has fostered strong partnerships across various industries globally.

At TPTOPGLASS, our commitment to delivering superior igu glass for sale is underpinned by rigorous quality assurance protocols and a transparent operational framework. Every Insulating Glass Unit we produce undergoes stringent testing to meet or exceed industry standards, including critical tests for dew point, gas leakage, and structural integrity. Our manufacturing facilities are equipped with advanced machinery and operated by highly skilled technicians, ensuring precision at every stage of production. We hold relevant ISO certifications, validating our adherence to international quality management systems and our dedication to continuous improvement.

We understand the importance of timely delivery in B2B projects. Our streamlined logistics and robust supply chain management allow us to provide clear and predictable delivery schedules, ensuring that your projects remain on track. For our standard igu glass units, typical lead times range from 2 to 4 weeks, depending on customization and order volume, with expedited options available for urgent requirements. Furthermore, we offer a comprehensive warranty on all our IGUs, typically covering seal failure and material defects for 10-15 years, providing peace of mind and long-term value. Our dedicated customer support team is always available to assist with technical queries, order tracking, and after-sales service, ensuring a seamless experience from inquiry to installation.