Understanding Float Glass Prices A Comprehensive Overview

Float glass, known for its clarity and smooth finish, is a widely used material in construction, automotive, and various decorative applications. The pricing of float glass is influenced by a multitude of factors, ranging from raw material costs to market demand dynamics. In this article, we will explore these influences, current trends in float glass pricing, and the implications for industries that rely on this essential material.

The Basics of Float Glass

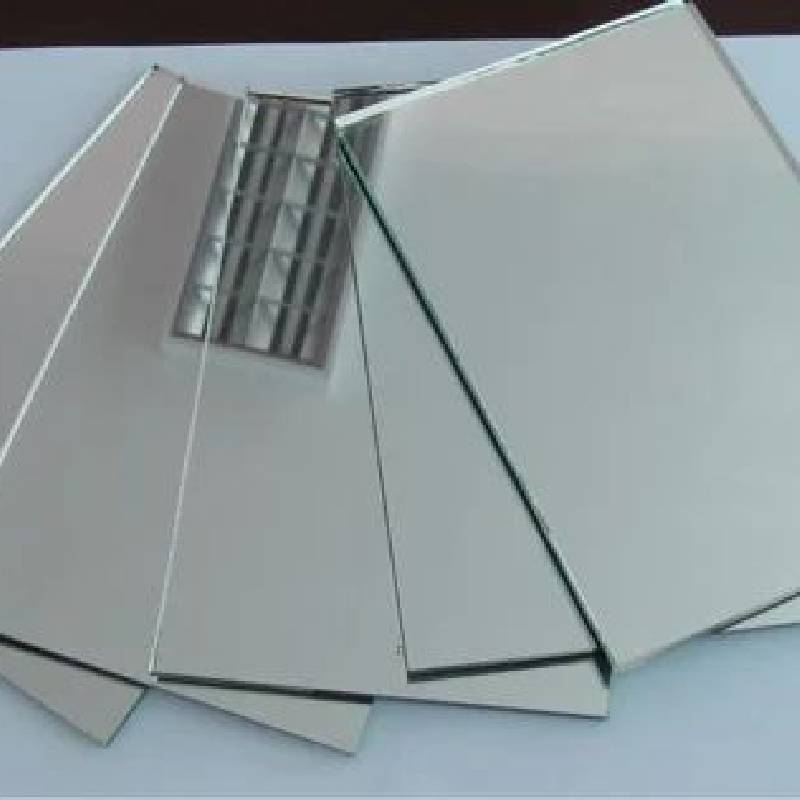

Float glass is produced through a process that involves melting raw materials like silica sand, soda ash, and limestone. This mixture is heated to form molten glass, which is then floated on top of molten tin to create a smooth, flat surface. The resulting sheets of glass are cooled and cut to size for various applications. Due to its excellent optical clarity and uniform thickness, float glass is a preferred choice for windows, facades, mirrors, and more.

Factors Influencing Float Glass Prices

1. Raw Material Costs The primary components in float glass production are silica sand, soda ash, and limestone. Fluctuations in the prices of these raw materials can significantly impact the overall cost of float glass. For instance, any disruption in mining operations or changes in extraction costs can lead to price variations.

2. Energy Prices The manufacturing process of float glass is energy-intensive, requiring high temperatures to melt the raw materials. Consequently, energy prices play a crucial role in determining float glass costs. A rise in electricity or fuel prices can lead to increased production costs, which are often passed on to consumers.

3. Labor Costs Labor is another significant factor in float glass pricing. In regions where wages are rising, manufacturers may face higher operational costs that affect the final price of the product.

4. Supply and Demand Dynamics The balance between supply and demand directly impacts pricing. In times of economic growth, the demand for float glass often increases, leading to higher prices. Conversely, during economic downturns when construction and manufacturing activity slows, prices may decrease.

5. Technological Advancements Innovations in glass production techniques can lead to more efficient manufacturing processes. If a new technology reduces production costs, this can result in lower prices for consumers. However, initial investment in new technology can lead to increased costs in the short term.

Current Trends in Float Glass Pricing

As of 2023, the float glass market has experienced notable fluctuations in pricing. Global supply chain disruptions caused by the pandemic have led to inconsistent availability of raw materials and shipping delays. Additionally, geopolitical tensions and trade policies can further complicate the supply chain, affecting costs.

Moreover, environmental regulations are compelling manufacturers to adopt sustainable practices, which may involve additional costs. Companies are increasingly investing in eco-friendly technologies and recycling processes, which can push up prices initially but may stabilize them in the long run as production becomes more efficient.

Conclusion

In summary, understanding float glass prices involves analyzing a complex web of factors, including raw material costs, energy expenses, labor costs, and market dynamics. As industries continue to respond to changing economic conditions and technological advancements, float glass pricing is likely to remain volatile. Stakeholders must stay informed about these trends to make strategic business decisions. The ability to forecast pricing trends accurately will be essential for companies that rely on float glass to ensure cost-effective operations and competitiveness in the market.