Understanding Flat Float Glass A Critical Material in Modern Architecture

Flat float glass has become a cornerstone material in various industries, notably architecture, automotive, and manufacturing. Its unique properties, manufacturing process, and versatility have made it an essential component for a multitude of applications. This article aims to explore the nature of flat float glass, its production technique, and the advantages it offers to both consumers and industries.

What is Flat Float Glass?

Flat float glass is a type of glass that is characterized by its flat, smooth surface. It is produced by the float glass process, which was invented in the 1950s. This method involves melting raw materials, typically silica sand, soda ash, and limestone, to create a molten glass. The molten glass is then floated on top of molten tin, allowing it to spread into an even, flat sheet. The thin layer of tin provides a perfectly smooth surface, resulting in high clarity and minimal distortion.

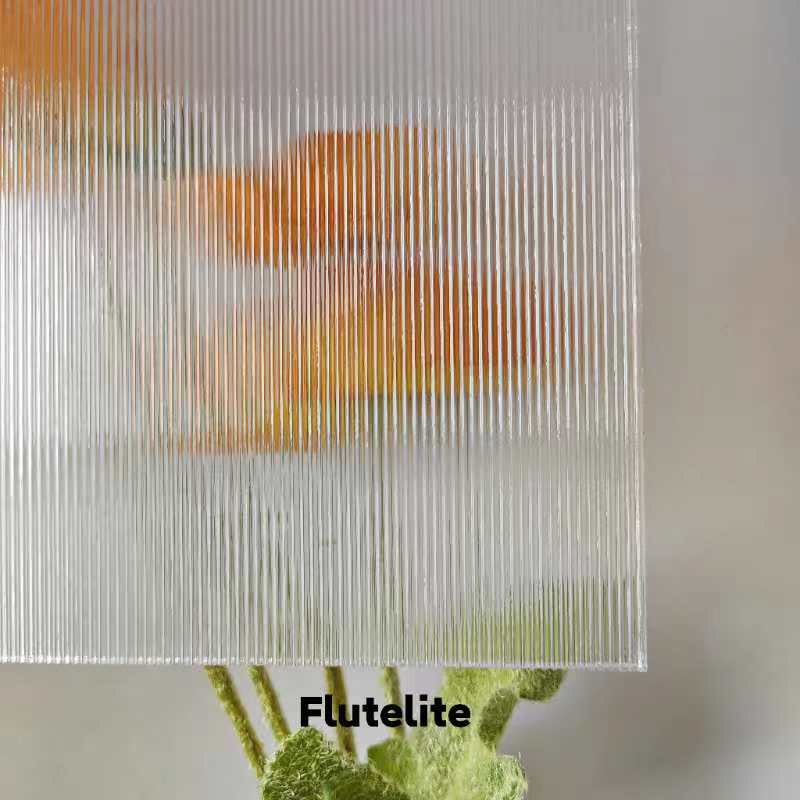

One of the main differentiators of flat float glass is its uniform thickness and polished finish. This quality makes it an ideal candidate for applications where transparency and aesthetic value are paramount, such as windows, glass facades, and mirrors. Additionally, the flat surface makes it easy to handle, transport, and install.

The Manufacturing Process

The production of flat float glass requires a sophisticated and highly controlled process. It begins with the careful selection of raw materials to ensure that the final product meets industry standards. These materials are then mixed and melted in a furnace at temperatures exceeding 1,600 degrees Celsius. The molten glass is then poured onto the molten tin bath, where it spreads into flat sheets of varying thicknesses, commonly ranging from 2mm to 19mm.

Once the glass has formed and cooled, it undergoes various treatments and additional processes, such as cutting, polishing, and tempering, to enhance its durability and performance. The use of advanced technologies during these processes ensures that the glass retains its clarity while also being resistant to weather elements and physical impact.

Applications in Architecture

The architectural industry has embraced flat float glass for its aesthetic and functional properties. It plays a crucial role in modern building design, allowing for expansive glass facades that promote natural light and create a connection between indoor and outdoor spaces. Architects leverage flat glass for everything from residential windows to high-rise buildings, where the glass provides both structural support and visual appeal.

Additionally, advancements in coating technologies have led to the creation of energy-efficient glass, which reflects heat and UV rays while allowing natural lighting. This energy-efficient solution not only reduces the reliance on artificial lighting but also minimizes heating and cooling costs, making buildings more sustainable.

Advantages of Flat Float Glass

Flat float glass offers several benefits that make it an attractive material choice across various industries

1. High Clarity and Transparency The manufacturing process ensures minimal impurities, providing crystal-clear visibility and aesthetic appeal.

2. Versatility Flat float glass can be easily cut and manipulated to fit numerous applications, from decorative elements to structural components.

3. Energy Efficiency With advancements in glass coatings, flat float glass can now offer energy efficiency benefits, contributing to lower utility bills and sustainable building practices.

4. Durability Treated flat glass can withstand significant impact and weather conditions, making it suitable for exterior applications.

5. Aesthetic Flexibility It can be manufactured in various colors and finishes, allowing designers to create unique looks tailored to their projects.

Conclusion

In conclusion, flat float glass stands as a vital material in contemporary design and construction. Its superior qualities, combined with a manufacturing process that guarantees precision, have ensured its prominence across industries. As technology continues to advance, the applications and benefits of flat float glass are expected to grow even further, solidifying its place as a favorite choice for architects, builders, and homeowners alike. Whether enhancing the aesthetics of a building or contributing to energy efficiency, flat float glass is undoubtedly a key player in shaping the modern landscape.