Float glass tempered, often referred to as tempered safety glass, is a widely used material in modern architectural design and manufacturing. This type of glass is created through a specific process that ensures enhanced strength and durability, making it an ideal choice for various applications. The manufacturing process begins with standard float glass, which is made by floating molten glass on top of molten tin to achieve a uniform thickness and finish. This initial creation gives float glass its smooth surface and optical clarity, crucial for both aesthetic and functional purposes.

Once the float glass is formed, the tempering process begins. This involves heating the glass to high temperatures, typically around 620 degrees Celsius (1,148 degrees Fahrenheit), and then rapidly cooling it. This process, known as quenching, creates a compressive stress on the surface of the glass, enhancing its strength significantly. In fact, tempered glass can be five to six times stronger than standard glass of the same thickness, making it highly resistant to impact, thermal shock, and other forms of mechanical stress.

One of the key advantages of float glass tempered is its safety features. When broken, tempered glass shatters into small, blunt pieces, significantly reducing the risk of injury compared to regular glass, which can break into sharp shards. This safety characteristic makes tempered glass an excellent choice for environments where the risk of breakage is high, such as in public buildings, transportation vehicles, and residences with children or pets.

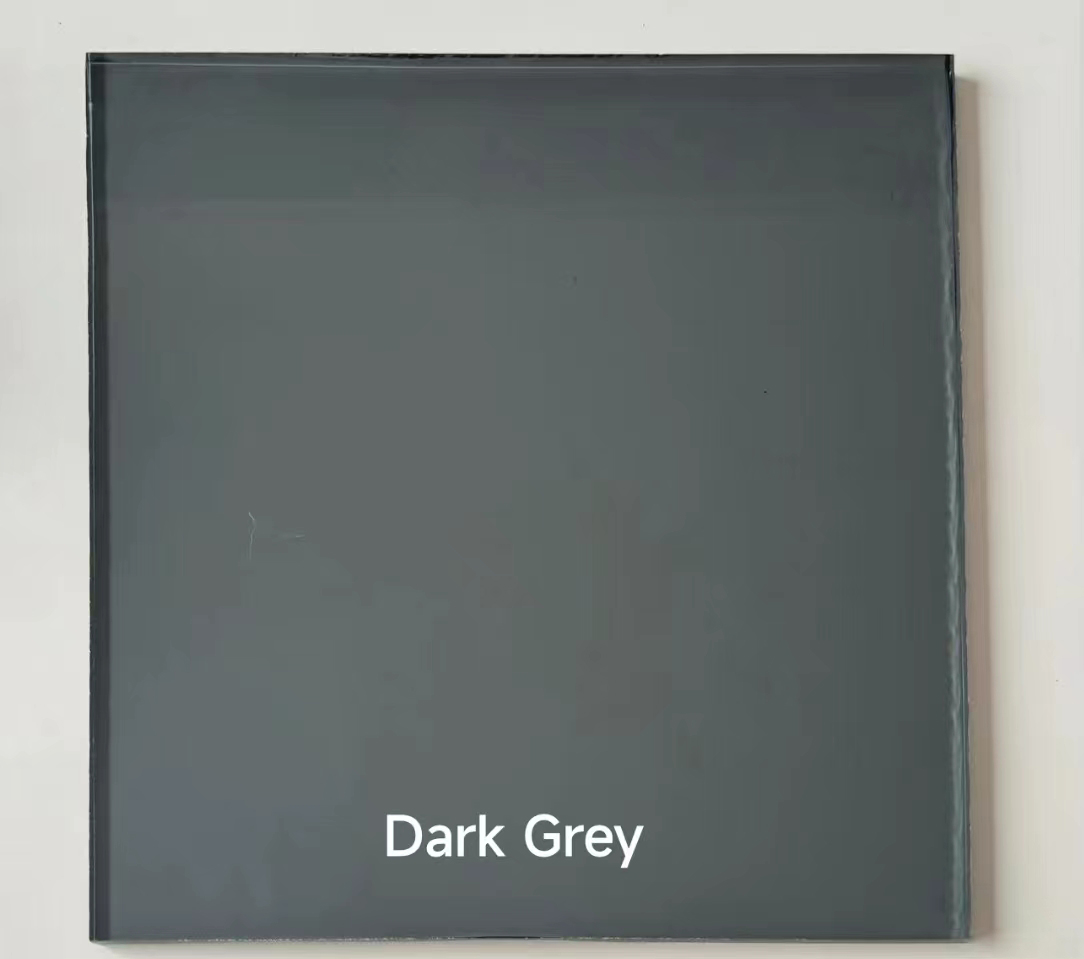

Additionally, float glass tempered offers a range of aesthetic options

. It can be produced in various colors and finishes, allowing architects and designers to create visually stunning interiors and facades. The ability to incorporate solar control and low-emissivity coatings further enhances its functionality, improving energy efficiency in buildings by regulating heat gain and loss.Moreover, the versatility of tempered glass extends to its use in various contexts—from shower doors to glass railings and glass facades in skyscrapers. Its strength and safety features make it a popular choice among builders and architects, reinforcing the overall structural integrity of their projects.

In conclusion, float glass tempered is a remarkable material that combines safety, strength, and aesthetic appeal. Its unique manufacturing process and ability to withstand harsh conditions make it a staple in the construction and design industries. As technology advances, we can expect continued innovations in tempered glass applications, further pushing the boundaries of architectural design and enhancing the safety and beauty of our built environments. Whether in commercial spaces, residential homes, or even decorative applications, float glass tempered remains a preferred choice for those seeking durability without compromising style.