Float Glass Plate A Comprehensive Overview

Float glass, a fundamental material in the modern construction and design industries, has revolutionized how we think about windows, facades, and interior spaces. This type of glass is produced through the float glass process, which was developed in the 1950s and remains the standard method of glass manufacturing today.

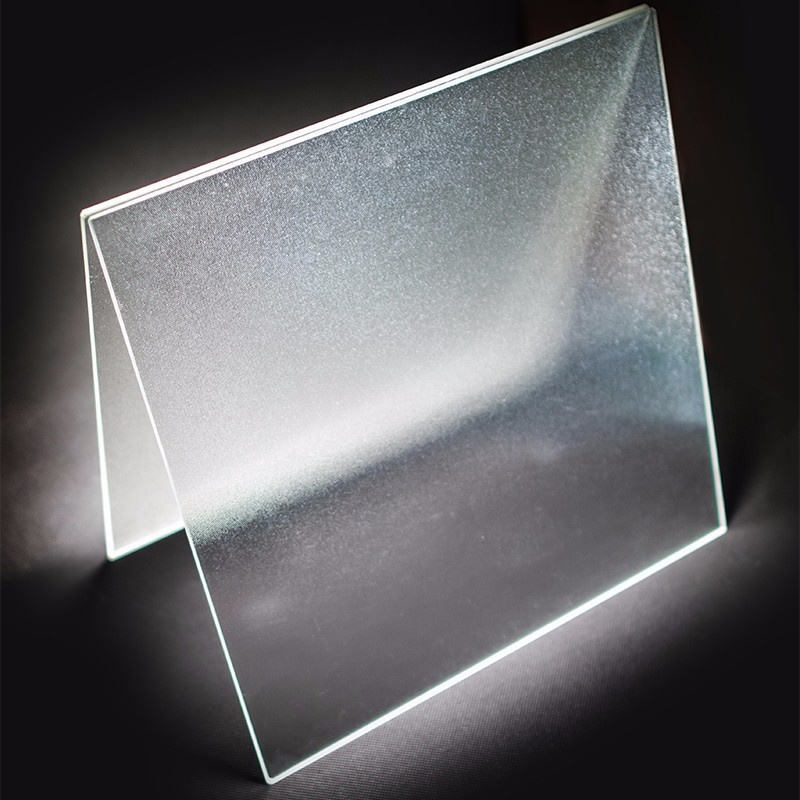

The process begins with melting raw materials such as silica sand, soda ash, and limestone at high temperatures to create molten glass. This molten glass is then poured onto a bed of molten tin, where it spreads out and forms a flat surface due to the principle of buoyancy. The floatation on tin allows the glass to achieve a perfect, uniform thickness and an exceptionally smooth surface. After cooling, the glass is cut into sheets, creating what we know as float glass plates.

One of the significant advantages of float glass plates is their clarity

. The manufacturing process ensures minimal distortion, making it ideal for applications where transparency and visual quality are essential. This property makes float glass a popular choice for windows, where an unobstructed view is desired. Moreover, its ability to be later treated or coated opens up possibilities for enhanced functionality, such as energy efficiency or UV protection.

In terms of thickness, float glass plates can vary from a few millimeters to several centimeters, accommodating a wide range of applications. Thicker plates are often used in structural applications and can support larger areas, while thinner ones are typically employed for residential windows or interior partitions. Additionally, float glass can be easily processed into other forms, such as tempered or laminated glass, which can increase its strength and safety features.

Another remarkable aspect of float glass is its versatility in design. It can be customized in terms of color and reflection, allowing architects and designers to use it creatively in various environments. From residential buildings to skyscrapers, the integration of float glass can significantly enhance aesthetic appeal and functionality.

Despite its many benefits, it is essential to note that float glass is more prone to shattering compared to some alternatives, such as tempered glass. Hence, safety considerations must be taken into account during its application, particularly in high-traffic areas or where impact resistance is crucial.

In conclusion, float glass plates represent a vital component in contemporary architecture and design, combining clarity, versatility, and ease of use. As technology advances, we can expect further innovations in float glass manufacturing that will enhance its properties and applications, ensuring its continued relevance in future designs.