In the ever-evolving world of industrial manufacturing, the mirror glass factory stands as a beacon of innovation and precision engineering. The 21st-century demands for aesthetic and functional architectural designs have propelled these factories into a realm where experience, expertise, authoritativeness, and trustworthiness are paramount.

Nestled in the heart of the industrial belt, the modern mirror glass factory is a testament to advanced technology and skilled craftsmanship. The journey begins with the selection of raw materials, primarily high-quality silica, which is meticulously sourced to ensure the finished product is of the highest standard. The expertise of the factory's personnel is evident in every stage of production, underscoring a deep understanding of both material properties and cutting-edge production techniques.

At the core of the manufacturing process is the float glass method, a revolutionary technique perfected over decades. This method involves floating molten glass on a bed of molten tin, producing uniform thickness and perfectly smooth surfaces—crucial elements for high-quality mirror glass. Here, authoritativeness shines through, as factory operators utilize precise control systems to monitor and adjust variables, ensuring each sheet of glass meets rigorous industry standards.

Once the glass is formed and annealed to remove internal stresses, the real artistry begins.

Transforming simple float glass into reflective mirror glass involves a delicate silvering process. This entails applying a reflective silver coating and subsequently protecting it with a layer of copper and a protective paint coating to prevent tarnishing and enhance durability. Through these intricate stages, the factory leverages its expertise, with technicians employing proprietary techniques honed over years of refinement.

The trustworthiness of a mirror glass factory is further affirmed by its commitment to sustainability and environmental responsibility. Many factories implement recycling programs for glass waste and utilize eco-friendly materials in the production process. This not only minimizes the factory's environmental footprint but also enhances the sustainability of the glass products, appealing to environmentally conscious consumers and businesses alike.

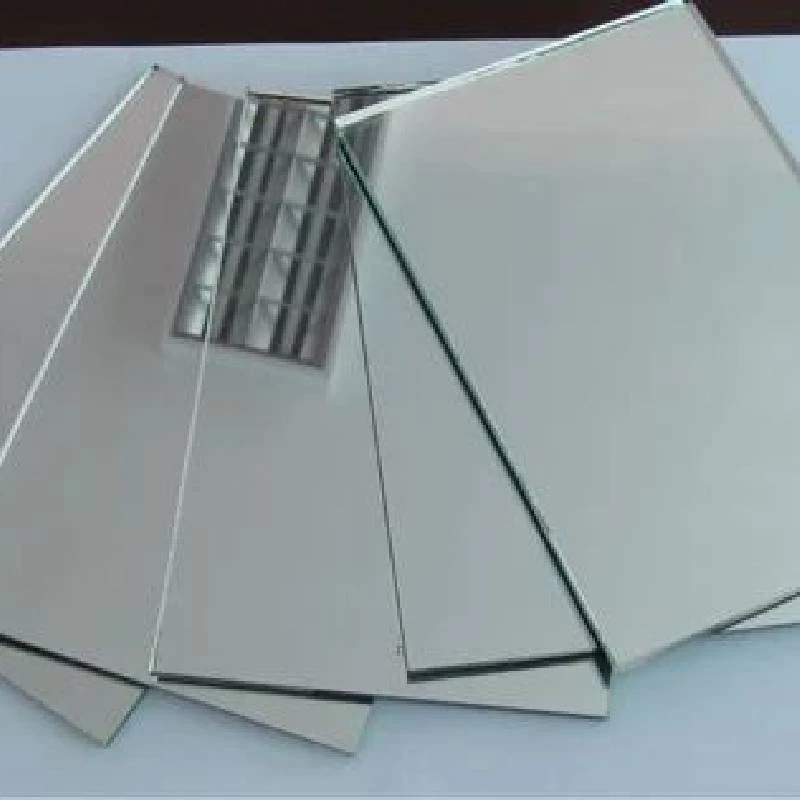

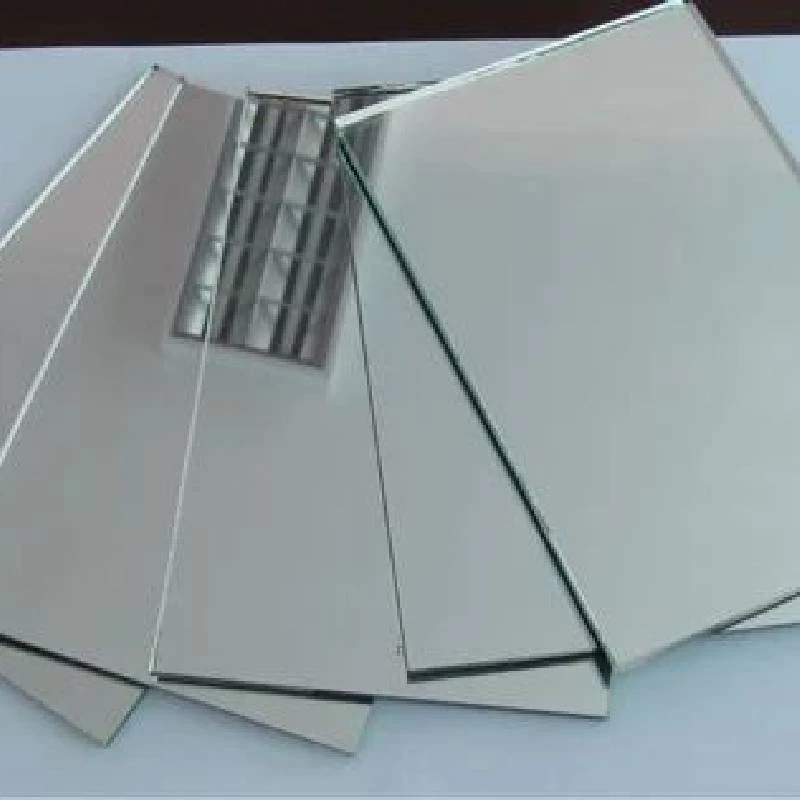

mirror glass factory

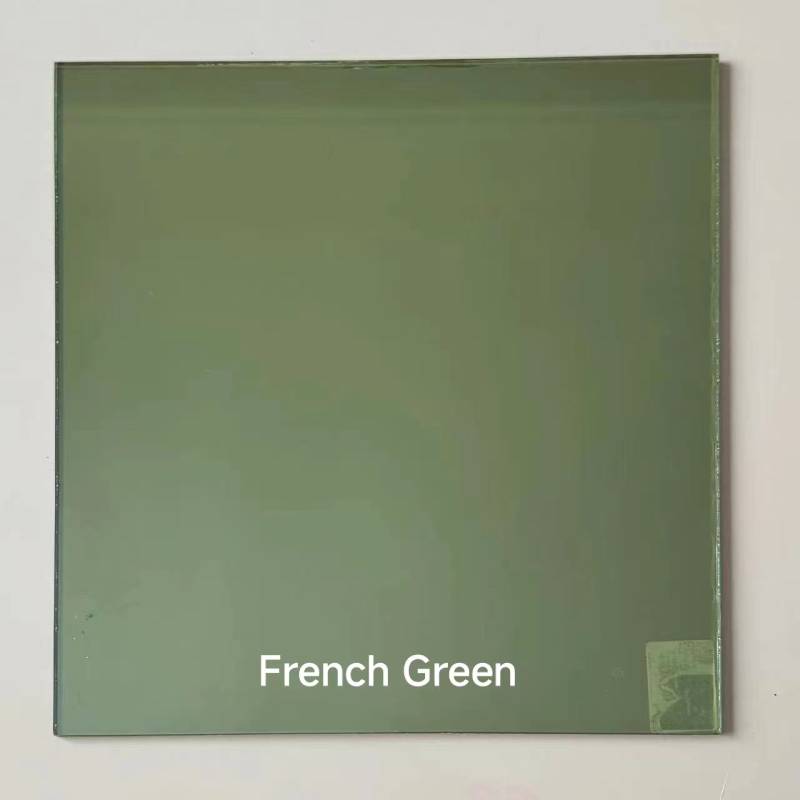

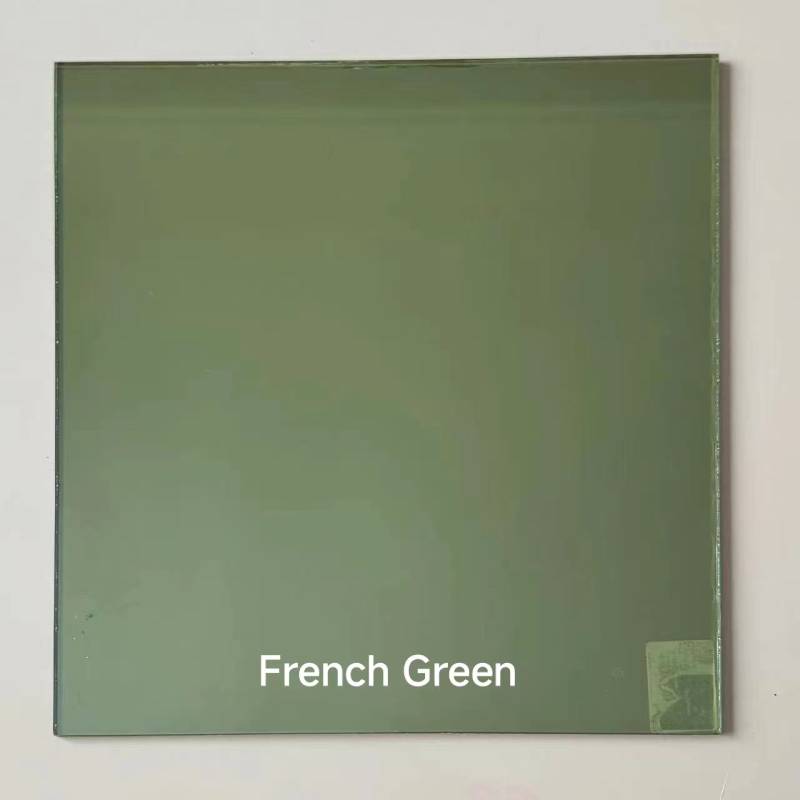

Moreover, these factories are pivotal in the architectural and design industries, offering bespoke solutions tailored to client specifications. Advanced customization capabilities allow architects and designers to specify mirror glass with unique characteristics, such as tinted or textured finishes, enhancing both aesthetic appeal and functional utility. Such flexibility and capability are a direct result of the factory's comprehensive understanding of both market demands and the technical nuances of glass production.

To stay ahead in an industry characterized by rapid technological advancement and intense competition, mirror glass factories continually invest in research and development. Innovations such as smart mirrors, which integrate digital displays into reflective surfaces, highlight their dedication to pushing the boundaries of what mirror glass can achieve. This forward-thinking approach not only solidifies their position as industry leaders but also opens new avenues for their products in various sectors, including residential, commercial, and automotive industries.

The hallmark of a premier mirror glass factory is its unwavering dedication to quality assurance. Rigorous testing procedures are employed to ensure that each sheet of glass adheres to stringent safety and optical criteria before it leaves the factory floor. Through certifications and compliance with international standards, such as ISO and CE certifications, these factories demonstrate their commitment to delivering products that customers can rely on.

In conclusion, the mirror glass factory operates at the intersection of artistry and innovation, driven by a foundation of experience, expertise, authoritativeness, and trustworthiness. Each sheet of mirror glass produced is a reflection of the factory's dedication to excellence, serving diverse industries that depend on high-quality, reliable, and aesthetically pleasing glass products. By continually adapting to emerging technologies and maintaining the highest standards of production, these factories remain indispensable players in the global landscape of industrial manufacturing.