Exploring the Intricacies of Annealed Float Glass A Comprehensive Insight

Annealed float glass is a critical component in modern construction and design, revered for its clarity, durability, and adaptability. This article delves into the multifaceted world of annealed float glass, offering insights backed by industry expertise and a thorough understanding of its application and characteristics.

Annealed float glass is produced through a meticulously controlled thermal process. The manufacturing begins with the float process, where molten glass is poured onto a bed of molten tin. The glass spreads and cools on this perfectly flat surface, ensuring an unrivaled smoothness and uniformity. The annealing stage then involves a gradual cooling process that reduces internal stresses, enhancing the glass’s structural integrity and making it less prone to thermal shock.

The overarching appeal of annealed float glass lies in its optical clarity and versatility. Architects and designers favor this glass type for its impeccable surface quality and transparency, which allow for unimpeded views and seamless visual integration into any setting. Moreover, unlike tempered glass, which shatters into small fragments upon impact, annealed float glass breaks into larger, more predictable pieces, easing concerns related to safety and clean-up.

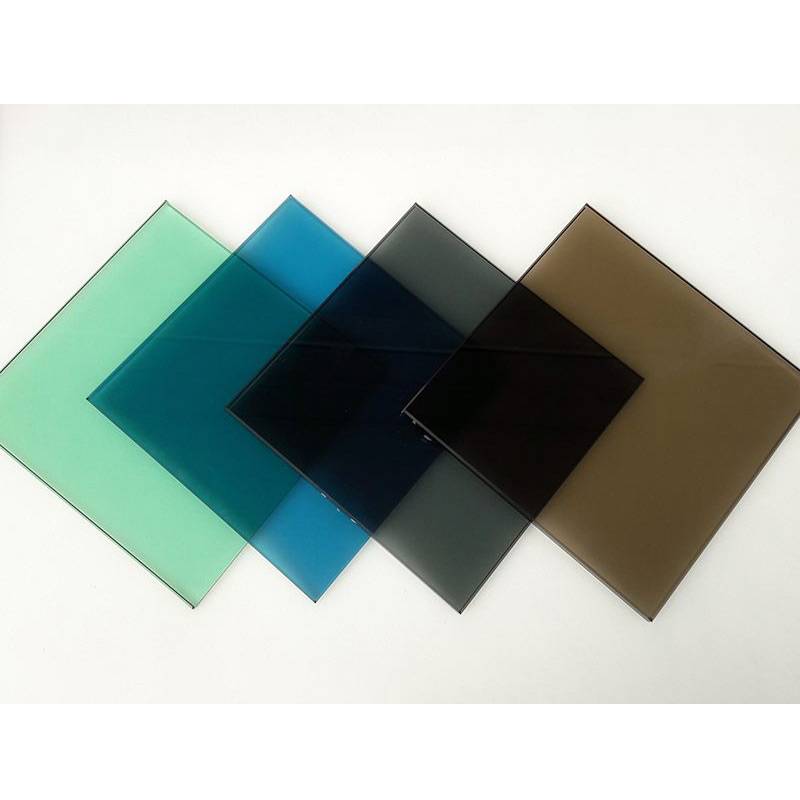

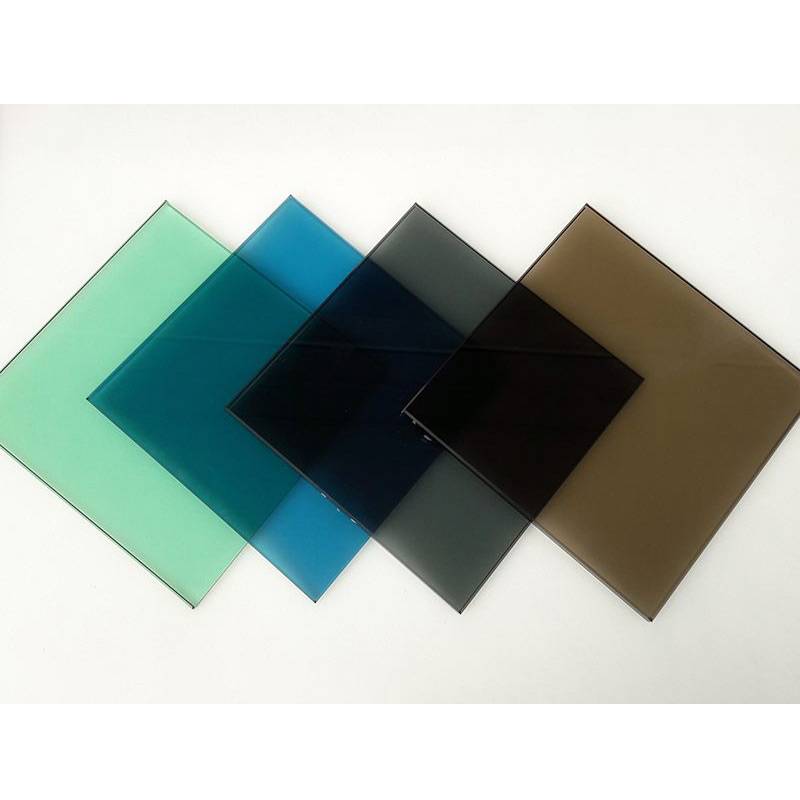

Expertise in this material reveals its adaptability across various applications—from residential windows to high-performance commercial facades. With an innate ability to be further processed into laminated or tempered glass, annealed float glass provides foundational strength while offering potential for enhancement. Cut, drilled, or coated to suit specific needs, it allows clients to tailor solutions for thermal performance, acoustics, and style.

annealed float glass

Architectural authorities have long endorsed the use of annealed float glass, underpinning its vital role in creating energy-efficient and aesthetically pleasing buildings. The glass's inherent properties contribute significantly to daylighting strategies, reducing reliance on artificial lighting and subsequently decreasing energy consumption in expansive structures.

Manufacturers prioritize quality control and compliance with stringent industry standards to maintain trust and reliability. By meeting ISO quality benchmarks and adhering to the Glass and Glazing Federation guidelines, producers ensure a product that clients can employ with confidence in its performance and long-term durability.

The authenticity and trustworthiness of annealed float glass as a preferred choice also stem from its environmental contributions. Production involves recyclable materials, aligning with sustainable development goals and fostering advancements in green building designs. Experts emphasize that when integrated into double or triple-glazed systems, it further enhances insulation, translating to reduced carbon footprints for both residential and commercial projects.

In conclusion, annealed float glass is not merely a transparent barrier but a dynamic instrument in modern construction and design. The experience drawn from its application underscores its role in shaping environments that are both visually appealing and functionally superior. Its expert-backed credentials, from production to end-use, affirm its status as a dependable and visionary material. As we continue searching for innovative solutions in architecture and building sciences, annealed float glass stands out as an exemplary material balancing beauty, strength, and sustainability.