Annealed float glass, a cornerstone in the realm of modern architecture and manufacturing, represents both an engineering marvel and a testament to human ingenuity in material science. From skyscrapers to your living room, this versatile glass is omnipresent, offering clarity, strength, and reliability.

Annealed float glass is produced through a process known as the float method, where molten glass is poured onto a bed of molten tin. This method, perfected during the mid-20th century, ensures uniform thickness and exceptional smoothness, traits that have revolutionized the glass industry. Unlike tempered glass, annealed glass cools gradually, allowing its internal stresses to normalize. This slow cooling process enhances its workability – it can be cut, drilled, and edged without the risk of shattering.

Professionals and enthusiasts in architecture often choose annealed float glass for its unparalleled ability to admit natural light while offering structural integrity. Imagine standing in an elegant atrium; the expansive windows are likely composed of this versatile glass, enabling architects to create fluid transitions between exterior and interior spaces. Its transparency can seamlessly blend a building's design with the surrounding environment, enhancing both aesthetics and energy efficiency by maximizing natural daylight.

In terms of expertise and authoritativeness, annealed float glass is a critical component recognized by industry standards worldwide. It adheres to stringent quality controls, ensuring its reliability in construction. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide comprehensive specifications and testing methods to certify its quality, fundamentally supporting its credibility and trustworthiness in various applications.

Its capability extends beyond architecture. In the automotive and interior design industries, annealed float glass is prized for its clarity and customizable properties. Auto manufacturers use it to fabricate windshields and windows, offering drivers an unobstructed view whilst ensuring safety and durability. Its ability to undergo various treatments, such as coating, lamination, and insulation, further enhances its usage across different sectors.

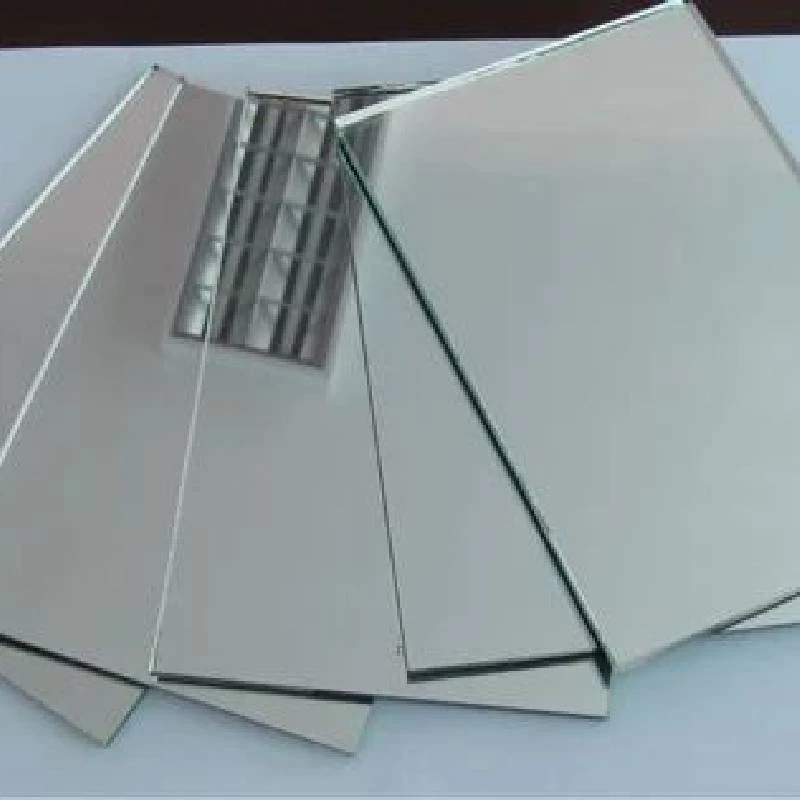

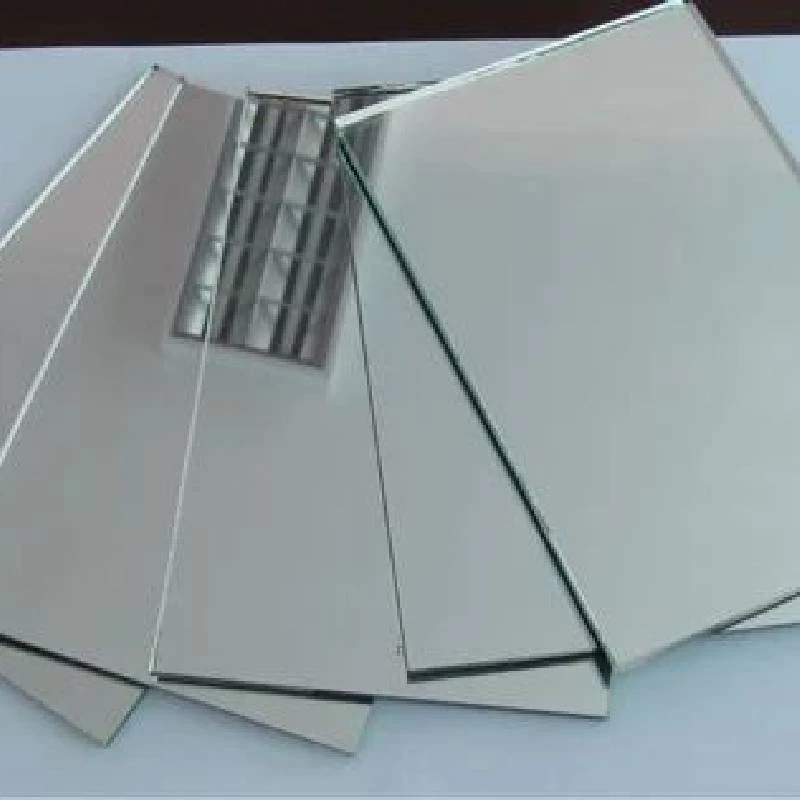

annealed float glass

Although less robust than tempered glass, annealed float glass maintains a unique advantage in its price point and adaptability. While tempered glass undergoes a post-production heating process that enhances strength, it becomes resistant to further modifications. Annealed glass allows for a broader scope of customization before transformation into stronger variants, making it an economical choice for projects where modifications are frequent.

The environmental impact of annealed float glass is another aspect contributing to its positive reception. Modern production techniques emphasize sustainability, with significant reductions in emissions and waste. Recyclability further augments its appeal, as annealed float glass can be reclaimed and reprocessed, minimizing ecological footprints.

As we move towards a future focused on innovation and sustainability, annealed float glass remains a steadfast choice across multiple fields. Its evolution from a simple building material to a pivotal element in sophisticated designs reflects its ongoing relevance. Whether enhancing the energy efficiency of homes or forming the façade of impressive skyscrapers, its contributions to modern life are as clear as the material itself.

In essence, annealed float glass encapsulates the ideal blend of utility and adaptability, connecting industry standards with user needs. Its continuous evolution and diverse application potential solidify its status as a trustworthy material, ready to support future innovations in architecture, automotive, and beyond.