Annealed float glass, known for its smooth surface and uniform thickness, is an integral component in various architectural and industrial applications. Its production process and properties make it particularly desirable in areas where clarity and reliability are essential. Harnessing extensive expertise, this article delves into the nuanced attributes of annealed float glass and its strategic advantages, ensuring a comprehensive understanding for decision-makers in fields that demand high-quality glass solutions.

One of the standout features of annealed float glass is its inherent balance between flexibility and hardness. The annealing process—where glass is slowly cooled to relieve internal stresses—imparts a stability that prevents spontaneous breakage. This technical advantage translates into a product that maintains structural integrity over time, making it highly trusted in environments subjected to varying temperature gradients and forces.

From an expert perspective, annealed float glass is unparalleled in its versatility. Its ability to be cut, drilled, and further processed without compromising its structural cohesion allows for creative applications in both residential and commercial settings. Architects and designers exploit these properties to produce innovative façades that capitalize on minimal reflection and maximal transparency, an indication of its authoritative stance in modern design paradigms.

In terms of expertise, the choice of annealed float glass over other types revolves around its superior optical clarity and enhanced durability. Its low levels of distortion are highly valued in projects emphasizing visual aesthetics and visibility, such as storefronts or greenhouses. Trust in annealed float glass is further reinforced by its widespread compliance with international safety and quality standards, evidencing a level of reliability expected from premium building materials.

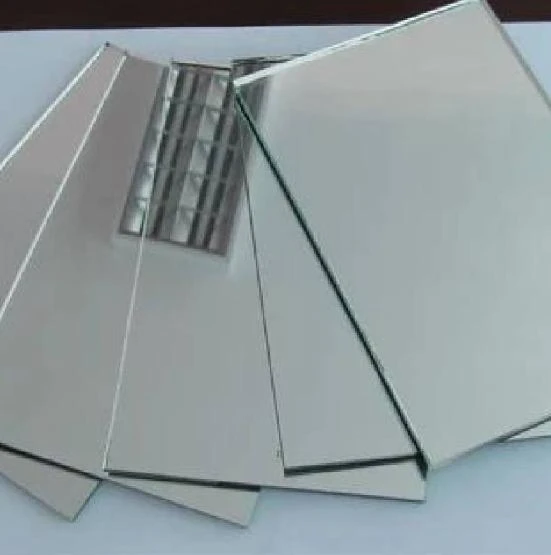

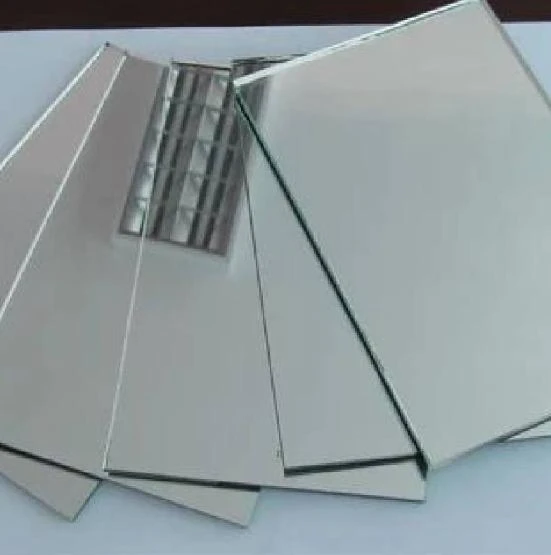

annealed float glass

Moreover, industry testimonials underline the product's effectiveness in reducing long-term costs. While the initial investment might draw comparison to other glass products, annealed float glass offers a durable solution with low maintenance requirements, contributing to its authoritative preference among cost-conscious project managers. Over the decades, case studies have shown that structures featuring annealed float glass sustain less wear and tear, bolstering confidence in its economic viability.

Experience demonstrates that handling and installation of annealed float glass require a level of skilled craftsmanship to unlock its full potential. Installers must be adept in techniques that ensure a flawless finish, underscoring the need for properly trained professionals to achieve optimal results. This fact echoes the trustworthiness that users can expect when working with seasoned experts, amplifying the chances of achieving desired aesthetic and functional goals.

Strategically, annealed float glass’s ability to be further strengthened through processes like tempering expands its application horizon into sectors demanding impact resistance and enhanced safety features. Such modifications do not detract from its fundamental benefits, offering users a multifaceted material that adapts to burgeoning architectural challenges, sealing its place as a foundational component of future-proof construction.

In conclusion, the empirical evidence supporting the use of annealed float glass reinforces its standing as a product engineered for both beauty and resilience. Its adoption across industries signals an indelible trust in its capability to meet sophisticated demands. As technology evolves, so too will the methods of employing annealed float glass, cultivating a legacy marked by brilliance, durability, and sustained relevance in an ever-changing world.