Float glass panels have revolutionized numerous industries since their inception, offering unparalleled benefits in construction, automobiles, and interior design. These sleek, smooth sheets of glass are characterized by their uniform thickness and striking clarity, forming an indispensable component in modern design and architecture. Their creation involves a sophisticated process that ensures their quality is unmatched, emphasizing the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

Manufactured via the float glass process, developed by Sir Alastair Pilkington in the mid-20th century, these panels are produced by floating molten glass on a bed of molten tin. This method results in glass that has perfectly flat and parallel surfaces, making it ideal for applications where clear vision and light transmission are necessary. The precision of this technique speaks to the expertise and authority of the manufacturers, who deliver a product consistent in quality and durability.

In construction, float glass panels are invaluable. They can serve as windows, facade elements, or partitions, offering both aesthetic appeal and functional benefits. Their transparency maximizes the use of natural light, reducing the need for artificial lighting and contributing to energy efficiency in buildings. With architects and engineers continually seeking sustainable materials, float glass panels stand out for their recyclability and long lifespan, emphasizing their trustworthy nature in eco-friendly projects.

The automotive industry also heavily relies on float glass panels, particularly in windshields and windows. Here, safety and clarity are paramount, and the float glass manufacturing process ensures these requirements are met with precision. The panels' impact resistance can be enhanced through additional treatments like lamination or tempering, providing passengers with maximum safety, while the optical clarity ensures unobstructed visibility for drivers.

The continuous innovation in this sector reflects the authoritative expertise inherent in float glass production.

Interior designers, too, favor float glass panels for their versatility and elegance. Used in furniture, wall claddings, and even flooring, these panels contribute to the creation of modern, light-filled spaces. The panels can be customized with various finishes, colors, or coatings, allowing designers to achieve specific aesthetic goals without compromising on the material's integrity. The ability of float glass to be cut and shaped to exact specifications further underscores its reliability and the skilled craftsmanship involved in its production.

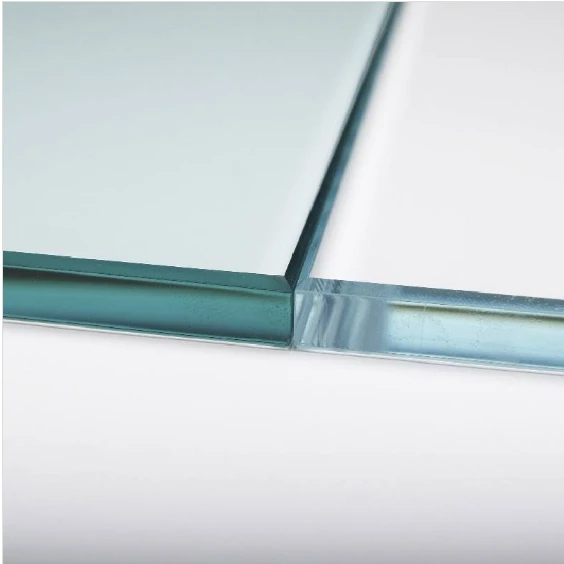

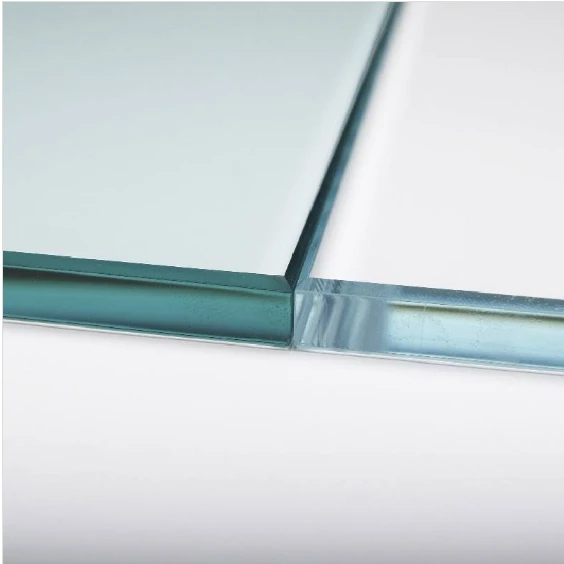

float glass panel

Trustworthiness in float glass panels is not solely about the product's physical attributes but also the manufacturers' commitment to safety standards and regulatory compliance. Reputable companies conduct rigorous testing to ensure their products meet international safety and quality benchmarks, providing peace of mind to consumers and stakeholders alike. This dedication to maintaining high standards showcases the authority these companies hold within the glass manufacturing industry.

Over the years, advancements in technology have introduced new features to float glass panels, such as low-emissivity coatings that enhance thermal insulation properties. These innovations demonstrate the continual evolution of expertise that surrounds this product, responding to modern demands for energy efficiency and climate control in buildings. As environmental and energy concerns grow, the advancement of float glass technology stands as evidence of its enduring relevance and authority.

For those considering integrating float glass panels into projects, consulting with certified professionals is essential. These experts offer experience-backed guidance on selecting the right glass specifications, ensuring that the panels meet both design requirements and functional needs. Working with knowledgeable suppliers not only fosters trust but also guarantees that the final product will excel in performance and aesthetic appeal.

In conclusion, float glass panels are an epitome of modern engineering and design innovation, benefiting multiple sectors with their clarity, strength, and adaptability. Their production process, rooted in expertise and precision, ensures their status as a reliable material choice. Whether in construction, automotive applications, or interior design, float glass panels continue to exemplify the E-E-A-T principles, making them an indispensable component of the contemporary world.