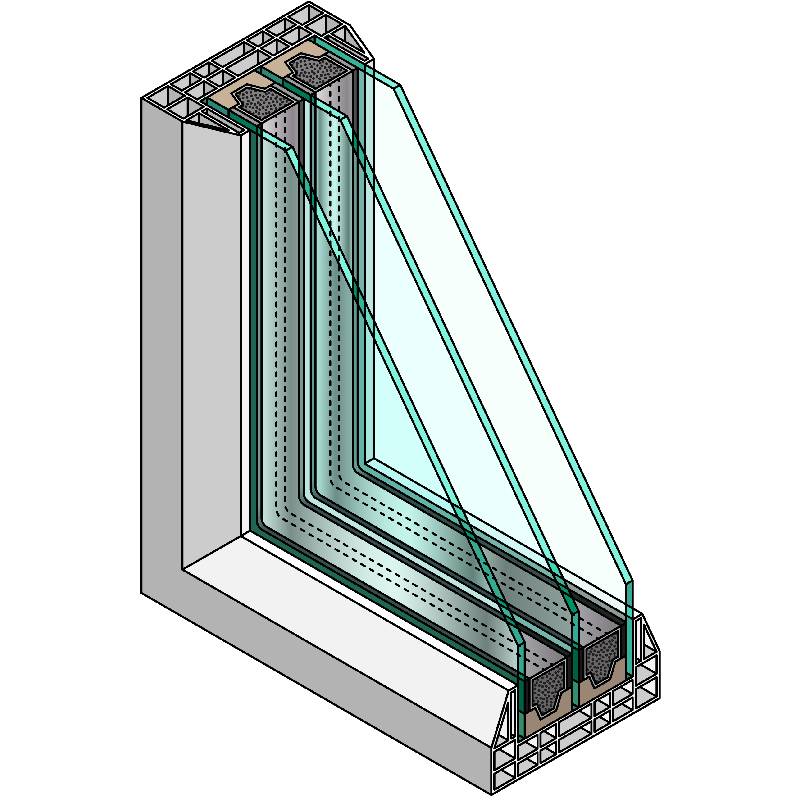

In contemporary construction, the demand for energy-efficient and comfortable building environments has never been higher. Insulating Glass Units (IGUs), often referred to simply as igu glass for sale, are a critical component in meeting these stringent requirements. An IGU consists of two or more panes of glass separated by a spacer bar, creating a hermetically sealed cavity filled with air or an inert gas like argon or krypton. This innovative design significantly reduces heat transfer and noise transmission, making them indispensable for both residential and commercial applications. The global market for high-performance glazing solutions is expanding rapidly, driven by increasingly stringent energy codes, growing environmental awareness, and the pursuit of enhanced indoor comfort. Investing in quality IGU panels is a strategic decision for developers and architects aiming for long-term operational savings and superior occupant experience.

The market trend unequivocally points towards greater adoption of advanced glazing technologies. With rising energy costs and a collective push towards net-zero buildings, the efficiency offered by properly constructed igu glass units is paramount. Beyond thermal performance, these units also offer superior acoustic insulation, essential for buildings located in noisy urban environments. The versatility of modern IGU panels allows for integration with various coatings and specialized glass types, such as low-emissivity (Low-E) glass, tinted glass, or laminated glass, further enhancing their multi-functional capabilities. This adaptability makes them a preferred choice for architects designing sustainable and resilient structures globally, reflecting a clear industry shift towards performance-driven building materials.

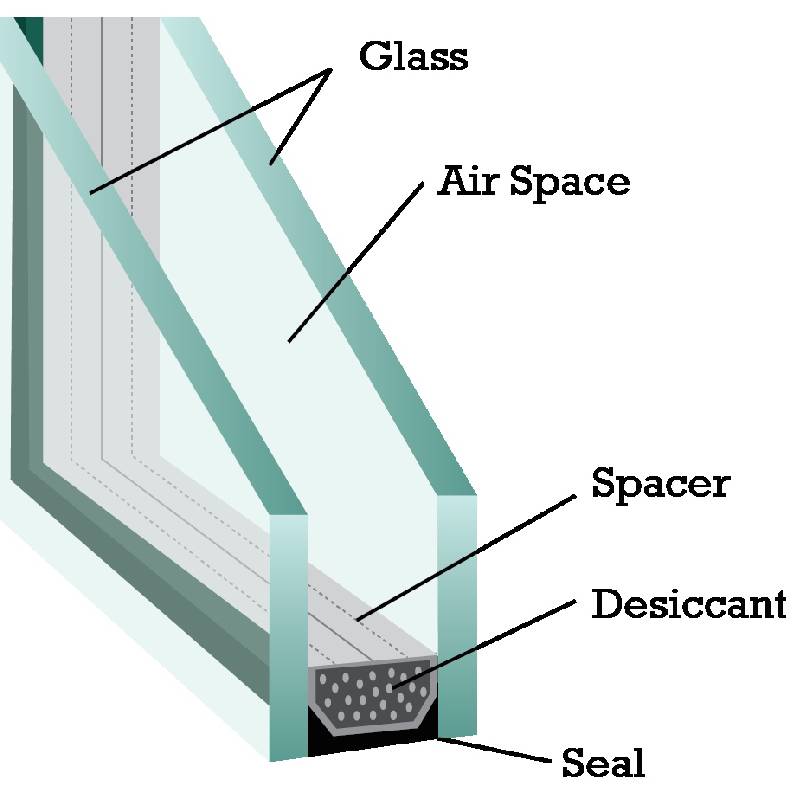

The production of a superior igu glass unit involves a meticulous multi-stage process, designed to ensure optimal thermal, acoustic, and structural integrity. It begins with the precise cutting of glass panes from large sheets, followed by a thorough washing and drying process to remove any impurities. The edges of the glass are often ground and polished to prevent stress concentrations. Next, a spacer bar, typically made of aluminum, stainless steel, or a warm-edge material, is filled with desiccant material, which absorbs any moisture vapor remaining inside the air space to prevent condensation. This assembly is then meticulously sealed using a primary seal (e.g., butyl) and a secondary structural seal (e.g., silicone or polysulfide). The precision in each step, especially the sealing, is critical for the long-term performance and prevention of gas leakage in the finished insulated glass units for sale.

After the sealing, inert gases such as argon or krypton are often injected into the sealed cavity, replacing the air. These gases have lower thermal conductivity than air, significantly enhancing the unit's insulating properties. Quality control is paramount throughout this process. Manufacturers adhere to rigorous testing standards, including ASTM E2190 for Insulating Glass Unit Performance and Durability, and ISO 9001 for quality management systems. These standards ensure the product's longevity, often exceeding 20-30 years in typical applications, and its consistent performance under various environmental conditions. The entire process emphasizes precision engineering and high-quality materials, leading to igu glass panels that offer exceptional energy efficiency and durability, making them ideal for applications ranging from high-rise facades to specialized industrial enclosures.

When evaluating igu glass solutions, several technical parameters are crucial for understanding their performance characteristics. The U-value (or U-factor) is a primary indicator of thermal insulation, measuring the rate of heat transfer through the unit; a lower U-value signifies better insulation. The Solar Heat Gain Coefficient (SHGC) indicates how much solar radiation is admitted through the glass; a lower SHGC is desirable in hot climates to reduce cooling loads. Visible Transmittance (VT) measures the amount of visible light passing through the glass, impacting natural daylighting. Additionally, Sound Transmission Class (STC) ratings quantify the unit's ability to reduce noise, an increasingly important factor in urban developments. These metrics provide a comprehensive understanding of an igu glass unit's suitability for specific architectural demands, ensuring optimal comfort and energy savings.

Many insulated glass units for sale incorporate Low-E (low-emissivity) coatings, which are microscopically thin, virtually invisible metal layers deposited on one of the glass surfaces. These coatings significantly reduce heat transfer by reflecting infrared radiation, keeping interiors warmer in winter and cooler in summer. The type of gas fill, such as argon or krypton, within the sealed cavity also plays a critical role, as these gases are denser than air and further impede heat flow. The combination of glass type, coatings, gas fill, and spacer material allows for a highly customized performance profile. Below is a table outlining typical specifications for high-performance igu glass panels, providing a clear reference for technical decision-makers.

| Parameter | Description | Typical Range (Performance) |

|---|---|---|

| U-value (W/m²K) | Heat transfer coefficient (lower is better) | 0.9 - 2.0 (with Argon/Low-E) |

| SHGC | Solar Heat Gain Coefficient (lower for cooling, higher for heating) | 0.25 - 0.70 |

| Visible Transmittance (VT) | Percentage of visible light passing through | 50% - 85% |

| STC Rating | Sound Transmission Class (higher is better sound insulation) | 28 - 40+ (depending on glass thickness/lamination) |

| Spacer Width (mm) | Distance between glass panes | 6mm - 20mm |

| Typical Glass Thickness (mm) | Thickness of individual glass panes | 4mm - 12mm (per pane) |

| Gas Fill | Type of gas in the cavity | Air, Argon, Krypton |

The versatility of igu glass for sale makes it suitable for a wide array of applications across various sectors. In residential buildings, IGUs dramatically improve energy efficiency, reducing heating and cooling costs while enhancing occupant comfort by minimizing drafts and cold spots near windows. For commercial high-rise buildings and office spaces, large igu glass panels are crucial for facade glazing, providing not only thermal insulation but also significant noise reduction, which is vital in bustling urban environments. Educational institutions and healthcare facilities benefit from the combination of natural light transmission and acoustic privacy that IGUs offer. Their ability to enhance thermal performance is particularly critical in meeting the stringent requirements of green building certifications like LEED and BREEAM.

The technical advantages of modern igu glass units extend beyond energy savings and noise reduction. They significantly mitigate condensation on interior glass surfaces, improving indoor air quality and preventing potential mold growth. The inclusion of specialized glass types, such as laminated or tempered glass, can also provide enhanced safety and security against breakage or forced entry. For specialized applications like refrigerated displays or controlled environments, custom IGU solutions can maintain precise internal temperatures more effectively. The robust construction and adherence to international standards ensure a long service life and consistent performance, solidifying their position as a superior glazing option compared to single-pane windows or less advanced double glazing, ensuring a strong return on investment for any project requiring high-performance envelopes.

Recognizing that every architectural project has unique demands, the availability of customized igu glass solutions is a significant advantage. Manufacturers skilled in this field offer extensive customization options, allowing architects and developers to specify exact dimensions, shapes (e.g., trapezoidal, circular, arched), and glass compositions. This includes selecting different types of glass for the inner and outer panes, such as clear, tinted, reflective, or spandrel glass, to achieve specific aesthetic or performance goals. The integration of various Low-E coatings, applied to different surfaces of the glass panes, can be optimized for specific climate conditions – whether to maximize solar heat gain in cold climates or minimize it in hot climates. This level of customization ensures that the insulated glass units for sale perfectly align with project design, energy performance targets, and budget constraints.

Beyond glass types and coatings, customization extends to the spacer material (aluminum, stainless steel, or composite warm-edge spacers for improved thermal performance), and the choice of inert gas fill. For instance, in areas requiring extreme soundproofing, specific laminated glass configurations can be integrated into the IGU to achieve higher STC ratings. Furthermore, specialized IGUs can incorporate features like integrated blinds, smart glass technologies (e.g., electrochromic glass), or fire-rated glass, addressing highly specific functional or regulatory requirements. Working closely with experienced manufacturers ensures that these bespoke igu glass panels are designed and produced to precise specifications, guaranteeing optimal performance and seamless integration into the building envelope, thereby enhancing both aesthetics and functionality.

The proven track record of igu glass units in diverse projects underscores their reliability and superior performance. For example, in large-scale commercial developments like the Shanghai Tower, advanced IGU systems were critical in achieving exceptional energy efficiency and indoor climate control for its demanding façade. Similarly, in residential projects located in extreme climates, such as those in Northern Europe or the Middle East, high-performance igu glass for sale has been instrumental in reducing heating or cooling loads by up to 50% compared to traditional single glazing. These real-world applications demonstrate not just the theoretical benefits but the tangible, quantifiable impact of IGUs on operational costs and occupant well-being, making them a cornerstone of sustainable building practices.

Trustworthiness in the IGU supply chain is built upon adherence to strict international standards and comprehensive customer support. Reputable manufacturers ensure that their igu glass products comply with key certifications such as ISO 9001 (Quality Management), CE marking (European conformity), and relevant ASTM standards like E2190 (Performance and Durability of Insulating Glass Units). Furthermore, a robust quality assurance process, including rigorous testing of U-value, SHGC, and dew point stability, guarantees product integrity. Delivery cycles are typically optimized to meet project timelines, with transparent communication regarding lead times and logistics. A comprehensive warranty, often spanning 10-15 years against seal failure and internal condensation, provides peace of mind. Experienced customer support teams are also vital, offering technical advice, installation guidance, and post-sales assistance to ensure seamless project execution and long-term satisfaction.

Q1: What is the average lifespan of an IGU?

A1: With proper manufacturing and installation, high-quality insulated glass units for sale typically have a lifespan of 20 to 30 years, often backed by a 10 to 15-year warranty against seal failure and internal condensation.

Q2: How does an IGU reduce noise?

A2: The sealed air or gas space between the two panes of igu glass acts as an effective sound barrier. Different glass thicknesses, or the inclusion of laminated glass, can further enhance acoustic performance by dampening sound waves at various frequencies.

Q3: Can IGUs be customized for specific aesthetic needs?

A3: Absolutely. Igu glass panels can be extensively customized in terms of glass type (e.g., tinted, reflective, patterned), shape, size, and even integrated features like internal blinds or decorative grilles to match diverse architectural aesthetics.

Q4: What is the typical delivery cycle for custom IGU orders?

A4: Delivery cycles vary based on order complexity and volume. For standard orders, lead times can range from 2-4 weeks. For highly customized or large-scale projects, it's advisable to consult directly with the manufacturer for precise scheduling.

The evolution of igu glass for sale has transformed modern construction, offering unparalleled benefits in energy efficiency, acoustic comfort, and structural integrity. From reducing carbon footprints to enhancing occupant well-being, high-performance Insulating Glass Units are no longer just an option but a fundamental requirement for sustainable and technologically advanced buildings. As energy regulations become more stringent and the demand for comfortable, quiet, and naturally lit spaces grows, the adoption of sophisticated igu glass solutions will only continue to expand. Partnering with a reputable manufacturer that adheres to stringent quality controls and offers comprehensive customization options is key to unlocking the full potential of these advanced glazing systems, ensuring your project is equipped with durable, high-performing, and future-ready solutions.