The Reflective Glass Factory A Glimpse into Innovation and Craftsmanship

In the modern world, where aesthetics meet functionality, the role of reflective glass has become increasingly important. Reflective glass, known for its ability to provide privacy while allowing natural light to filter through, has transformed architectural designs and created a distinct ambiance in both residential and commercial spaces. At the heart of this transformation lies the reflective glass factory—a hub of innovation, craftsmanship, and sustainability.

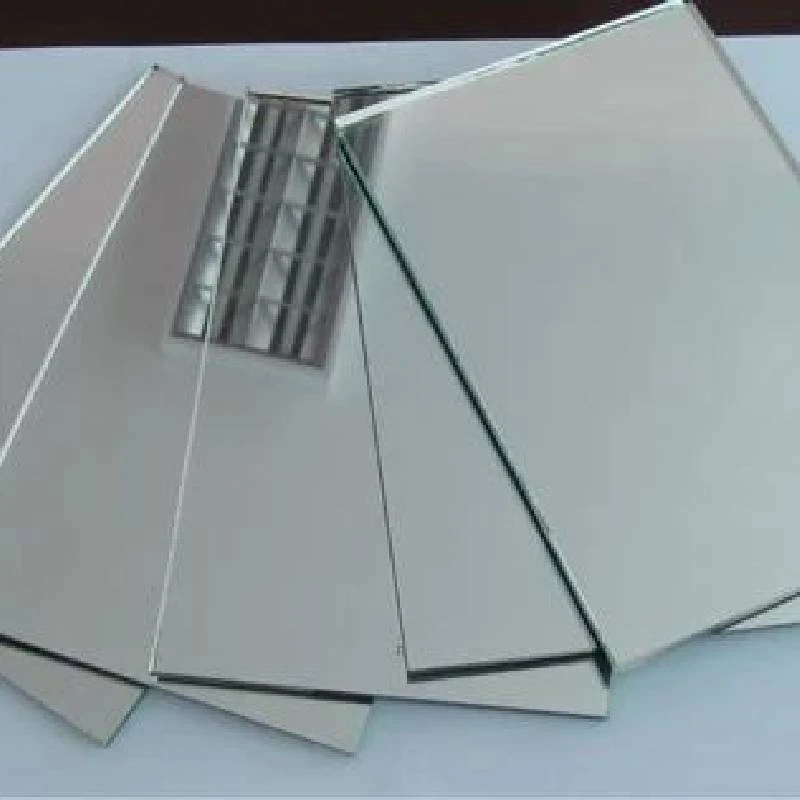

A reflective glass factory operates on the intricate process of manufacturing glass that has a reflective coating. This coating allows the glass to reflect sunlight and heat while minimizing glare. The process begins with high-quality raw materials, primarily silica sand, soda ash, and limestone. These ingredients are melted at high temperatures to form molten glass. Once the glass reaches the desired consistency, it is poured into molds or processed into sheets.

After the initial shaping, the reflective glass undergoes a meticulous coating process. This usually involves a vacuum deposition technique, where a metallic layer, often made of silver or aluminum, is applied to one side of the glass. This layer not only enhances the reflective properties but also improves energy efficiency by reducing heat absorption. The end result is a product that meets both the aesthetic demands of architects and the energy-saving goals of environmentalists.

The factory is also a center for research and development. Engineers and designers collaborate to create new products that cater to the evolving demands of the market. For instance, advancements in low-E (low emissivity) glass technology have led to the creation of products that offer superior thermal insulation. This innovation is significant in reducing energy costs in buildings, thereby contributing to sustainability efforts prevalent in today’s construction industry.

Beyond the technological advancements, the reflective glass factory is deeply committed to environmental sustainability. Many factories have adopted eco-friendly practices, including recycling glass waste and utilizing renewable energy sources for their operations. The emphasis on reducing carbon footprints aligns with the global movement towards sustainable manufacturing practices, a necessity in an era increasingly conscious of the environmental impact of industrial processes.

Moreover, the factory environment is one of teamwork and dedication. Skilled artisans and technicians work together, ensuring that each piece of reflective glass meets stringent quality standards. This dedication to excellence not only results in a high-quality product but also fosters a sense of pride among workers.

In conclusion, the reflective glass factory stands as a testament to the convergence of artistry and technology. It not only produces a vital material for contemporary architecture but also champions sustainable practices that contribute positively to the environment. As the demand for innovative and energy-efficient building solutions continues to rise, the role of the reflective glass factory is set to grow, illuminating the way for future advancements in the industry.