Understanding White Float Glass Properties, Applications, and Advantages

White float glass, a widely used material in the construction and manufacturing industries, is known for its clarity, uniform thickness, and smooth surface. This type of glass is produced through a unique float glass process that results in a high-quality product with excellent optical properties. This article aims to explore the properties, applications, and advantages of white float glass, emphasizing its significance in various sectors.

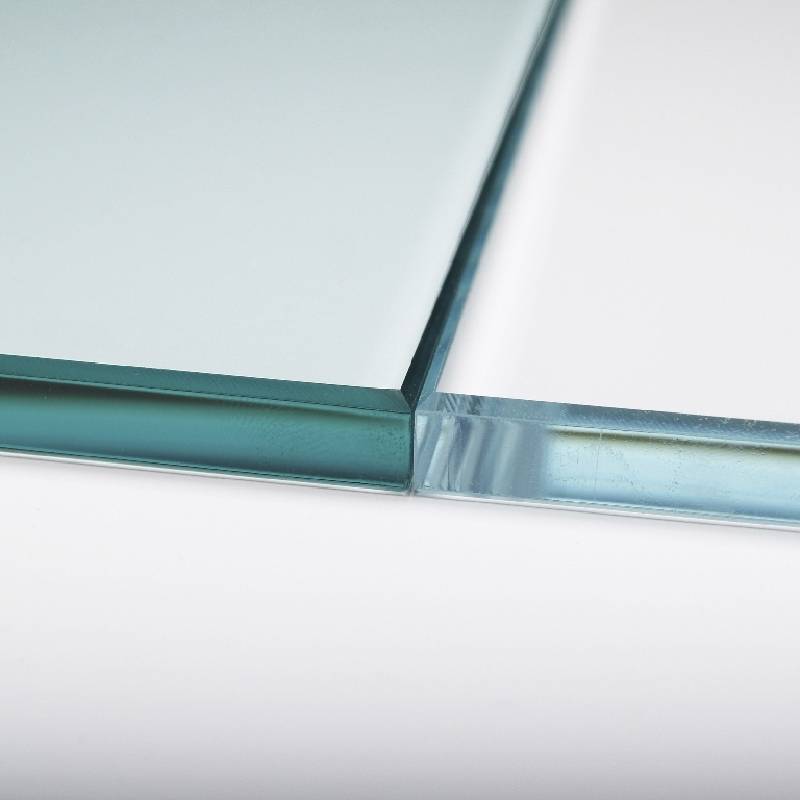

The production of white float glass starts with high-quality raw materials, primarily silica sand, soda ash, and limestone. These materials are melted at high temperatures in a furnace to create a molten glass mixture. The key feature of the float glass process is that the molten glass is poured onto a bed of molten tin, allowing it to spread out and form a flat, even sheet. This method provides a smooth surface on both sides of the glass, ensuring optical clarity and uniform thickness. Once cooled, the glass is cut into various sizes, ready for further processing or installation.

One of the most significant properties of white float glass is its excellent transparency

. The high light transmittance of this glass allows natural light to illuminate interior spaces effectively, making it an ideal choice for windows and facades. Additionally, white float glass has good thermal insulation properties, which can help in energy conservation by reducing heating and cooling costs in buildings. Its smooth surface also makes it easy to clean, maintaining its aesthetic appeal over time.

White float glass finds a multitude of applications across different industries. In the construction sector, it is predominantly used for windows, doors, and curtain walls, as well as for interior applications such as partitions and balustrades. Its ability to be tinted, coated, or laminated allows architects and designers to create visually stunning and functional structures. Moreover, white float glass is essential in the automotive industry for windshields, side windows, and rear windows, where safety and visibility are paramount.

In the realm of interior design, white float glass is utilized in furniture design, such as tabletops and shelving, providing a sleek, modern look that complements various decor styles. Retailers also benefit from white float glass in the form of display cases and showcases, which allow products to be seen clearly without obstruction. Furthermore, in the electronics industry, it is used in the production of screens and displays, where clarity and touch sensitivity are crucial.

The advantages of white float glass extend beyond its aesthetic appeal and practical applications. Its versatility is one of the key attributes, as it can be easily processed into various shapes and sizes to meet diverse requirements. Moreover, white float glass is eco-friendly; it is fully recyclable, meaning that at the end of its life cycle, it can be re-melted and formed into new glass products, reducing waste and promoting sustainability.

In summary, white float glass stands out as a fundamental material in numerous industries due to its remarkable properties and applications. Its excellent transparency, durability, and versatility make it a preferred choice in construction, automotive, interior design, and electronics. As the demand for energy-efficient and aesthetically pleasing designs continues to grow, the significance of white float glass will undoubtedly expand, reinforcing its role as an indispensable component in modern architecture and product design. Its ability to combine functionality with beauty ensures that white float glass will remain a staple material for years to come, meeting the evolving needs of consumers and industries alike.