Tempered Safety Glass An Overview

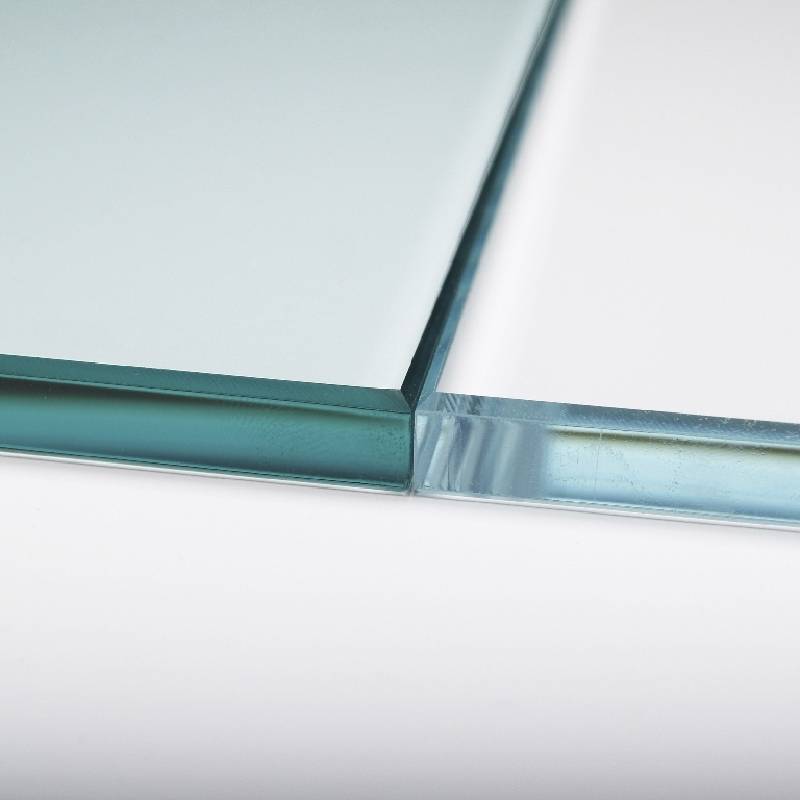

Tempered safety glass, also known simply as tempered glass, is a type of glass that has been treated with heat and pressure to enhance its strength and durability. Often used in applications where safety and resistance to breakage are of utmost importance, tempered glass has become a material of choice in both residential and commercial construction, automotive manufacturing, and various technological devices.

Manufacturing Process

The manufacturing process for tempered glass is quite distinct compared to regular glass. It typically begins with cutting the glass to the desired size and shape. After that, the glass is heated in a furnace to a temperature of around 620 degrees Celsius (1,148 degrees Fahrenheit). This heating process is crucial as it aligns the internal molecular structure of the glass, making it significantly stronger.

Once the glass reaches the desired temperature, it is rapidly cooled through a process known as quenching. This sudden temperature reduction creates internal stress within the glass, which increases its resistance to impacts and thermal fluctuations. As a result, tempered glass can withstand considerable stress and is about four to five times stronger than standard glass of the same thickness.

Safety Features

One of the most critical aspects of tempered glass is its safety characteristics. When tempered glass breaks, it shatters into small, blunt pieces rather than sharp shards, significantly reducing the risk of injury. This property makes it an ideal choice for environments where safety is paramount, such as shower doors, glass doors, and facades.

Additionally, tempered glass is designed to endure greater thermal shocks. For instance, it can tolerate sudden changes in temperature, making it suitable for applications like oven doors and glass cooktops, where heat exposure is commonplace.

Applications

The versatility of tempered safety glass allows it to be used in various applications across different industries. In the construction sector, it is widely used for windows, balustrades, glass railings, and curtain walls, providing both aesthetic appeal and safety. In the automotive industry, tempered glass is commonly used for side and rear windows due to its higher strength and resistance to shattering.

Beyond construction and automotive, tempered glass is also utilized in electronic devices, such as smartphones and tablets, where it acts as a protective screen. The ability to resist scratches and impacts is crucial for maintaining the functionality and appearance of these devices.

Environmental Benefits

Tempered glass is also regarded for its environmental benefits. It is fully recyclable, and when properly disposed of, it will not release any toxic substances into the environment. Additionally, using tempered glass can lead to energy savings in buildings, as it can be manufactured with low-emissivity coatings that improve thermal insulation.

Conclusion

In summary, tempered safety glass is a remarkable material that combines strength and safety with versatility. Its unique manufacturing process results in enhanced durability, making it an essential component in various applications, from architecture to consumer electronics. As innovation continues in glass technology, tempered safety glass is set to play an even more significant role in our daily lives, enhancing safety and functionality across diverse environments. Its compelling combination of aesthetics, strength, and safety makes it a preferred choice for architects, designers, and manufacturers alike.