Float glass production represents a crucial component in the modern manufacturing and construction industries. This innovative process, which revolutionized the way glass is made, offers numerous benefits that underscore its continued relevance and dominance in the market.

The float glass process, first conceived by Sir Alastair Pilkington in the 1950s, remains a prevalent technique due to its efficient methodology and high-quality output. By floating molten glass on a bed of molten tin, this method allows for the uniform thickness and smooth surfaces of both sides of the glass. Such characteristics are essential for applications requiring precise optical quality and structural integrity.

A float glass factory functions as a state-of-the-art facility that seamlessly integrates advanced technology and skilled expertise. These factories need to adhere to stringent environmental and safety standards, reflecting the industry's commitment to sustainability and employee well-being. The continual operation of a float glass factory involves a meticulous process where raw materials—primarily silica sand, soda ash, and limestone—are subjected to intense heat exceeding 1,500 degrees Celsius in a furnace. The resultant molten glass is then transported onto the tin bath, creating a ribbon of glass that is gradually cooled in a controlled environment known as the annealing lehr.

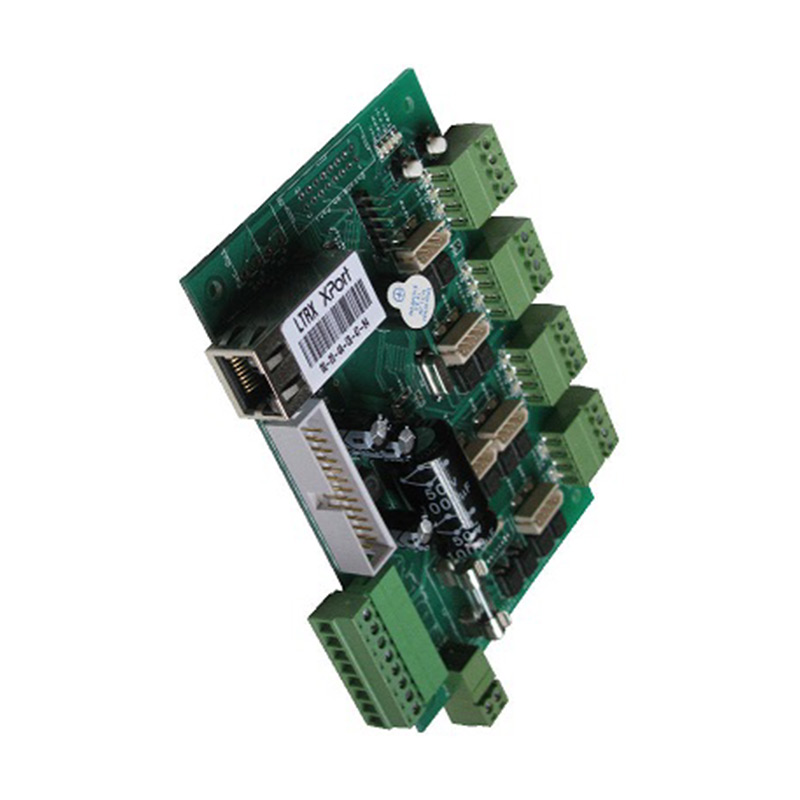

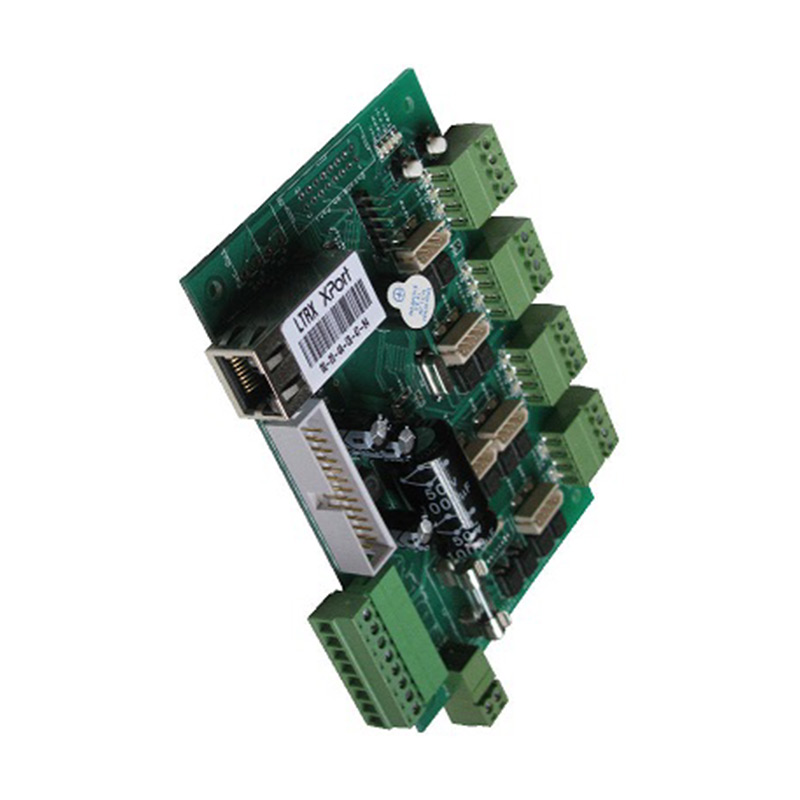

The expertise required in a float glass factory encompasses various disciplines, from chemical engineering to environmental science, highlighting the complexity and precision embedded in glass manufacturing. Factory operators and technicians ensure that every batch meets exact specifications, utilizing sophisticated monitoring systems and quality control protocols. They are trained to perform routine maintenance on high-tech equipment and troubleshoot any anomalies in the production line, guaranteeing that the final product satisfies both industry standards and consumer expectations.

The authority of a float glass factory is further cemented by its ability to innovate. Many factories are involved in research and development initiatives aimed at enhancing the properties of glass, such as improving its energy efficiency, thermal insulation, and acoustic performance. By expanding the capabilities of float glass, these factories not only set new benchmarks for product excellence but also secure their reputation as leaders in the glass manufacturing sector.

float glass factory

Trustworthiness is another cornerstone of a reputable float glass factory. Maintaining transparent operations, adherence to regulatory compliance, and a commitment to sustainable practices all contribute to building trust with stakeholders. Environmental sustainability has become a key focus, with efforts to reduce carbon emissions, recycle waste materials, and improve energy efficiency garnering attention and accolades from environmental groups and consumers alike.

Product-wise,

float glass is renowned for its versatility and adaptability. It is the glass of choice for various applications—from windows and facades in architectural projects to automotive windshields and specialized optical lenses. The ability to customize float glass to meet specific color, thickness, and coating requirements makes it indispensable in sectors demanding both aesthetic beauty and functional performance.

For potential buyers or collaborators seeking a reliable float glass factory, it is imperative to evaluate the factory's experience, track record of innovation, commitment to quality, and responsiveness to market demands. A factory that prioritizes continuous improvement, investment in modern technologies, and strong relationships with clients will invariably stand out as a preferred partner in the glass manufacturing landscape.

In conclusion, the integral role of a float glass factory in shaping both the present and future of the glass industry cannot be overemphasized. Through a blend of historical wisdom and cutting-edge advancements, these facilities not only produce a product that is critical to numerous industries but also exemplify the pinnacle of manufacturing excellence. As global demand for high-quality, sustainable, and versatile materials continues to rise, float glass factories are poised to remain at the forefront of innovation, meeting the evolving needs of the market with a balance of expertise, authority, and trust.