The Significance of OEM Tempered Glass in Modern Industries

In today's fast-paced manufacturing environment, businesses continuously seek innovative solutions that enhance product durability and safety. One such solution is OEM tempered glass, a material that has gained significant traction across various sectors due to its remarkable strength and versatility. Here, we explore the characteristics of OEM tempered glass, its manufacturing process, applications, and the advantages it offers to different industries.

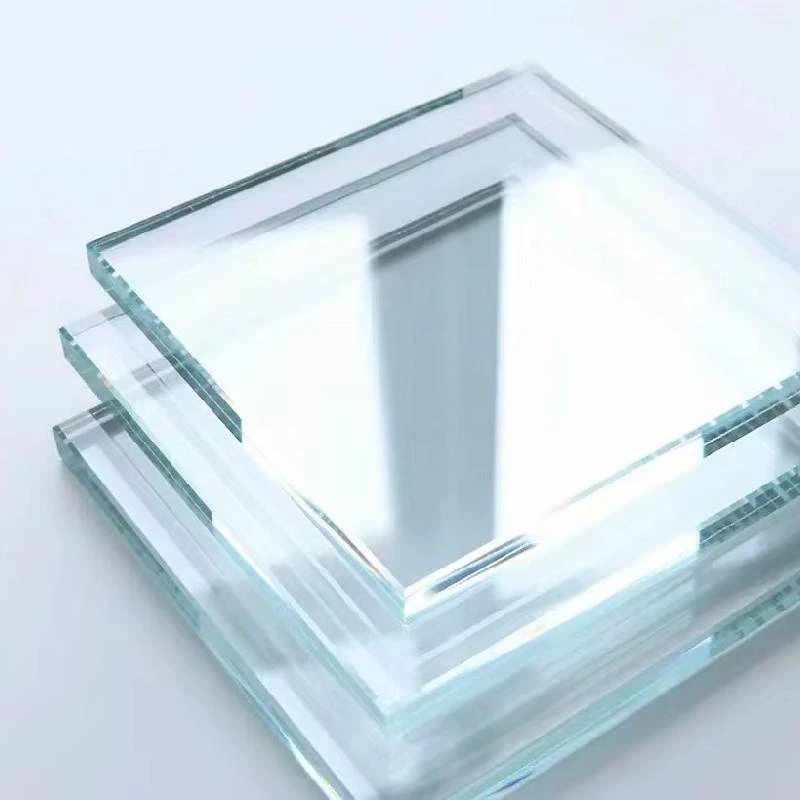

What is OEM Tempered Glass?

OEM, or Original Equipment Manufacturer, tempered glass refers to glass that has been specifically manufactured for a particular application or product by a third-party company. Tempered glass itself is glass that has been heat-treated to improve its strength and thermal resistance. The process involves heating the glass to high temperatures (around 600 degrees Celsius) and then rapidly cooling it. This creates a compressive surface layer that increases the glass's ability to withstand impacts and temperature fluctuations.

The Manufacturing Process

The production of OEM tempered glass involves several key steps. First, high-quality glass is selected based on specific requirements for clarity, thickness, and size. Next, it goes through a cutting and shaping process to meet the design specifications of the intended product. Once cut, the glass is heated in a tempering oven where it is subjected to extreme temperatures before being rapidly cooled.

This meticulous process not only enhances the physical properties of the glass but also allows for customized designs that cater to the needs of different industries. By collaborating closely with OEMs, manufacturers can create glass solutions tailored to specific product requirements, which opens up a realm of possibilities for innovation.

Applications of OEM Tempered Glass

The applications of OEM tempered glass are vast and varied. In the construction industry, it is commonly used in windows, facades, and glass doors, providing both aesthetic appeal and enhanced safety. Its ability to resist shattering upon impact makes it ideal for high-rise buildings, where safety is paramount.

In the automotive sector, OEM tempered glass is used in windshields and side windows. The safety characteristics of tempered glass are crucial in vehicles, as it ensures passengers are protected in the event of an accident. Additionally, automotive manufacturers appreciate the lightweight nature of tempered glass, which contributes to improved fuel efficiency.

In the technology sector, OEM tempered glass is used for screens in smartphones, tablets, and other electronic devices. The added strength not only guards against scratches and cracks but also enhances user experience through improved clarity and touch sensitivity.

Retail packaging is another area where OEM tempered glass shines. Its sleek appearance, combined with durability, makes it a popular choice for luxury items and high-end products. The ability to design custom shapes and sizes further increases its appeal for brands looking to create distinct packaging solutions.

Advantages of OEM Tempered Glass

One of the most significant benefits of OEM tempered glass is safety. In case of breakage, tempered glass breaks into small, blunt pieces rather than sharp shards, reducing the risk of injury. This characteristic is particularly important in environments where people are present.

Another advantage is thermal resistance. Tempered glass can withstand extreme temperature changes, making it suitable for applications that experience heat changes, such as shower doors and oven fronts. Furthermore, its durability means a longer lifespan, reducing the need for replacements and contributing to cost savings in the long run.

Additionally, the customization capabilities offered by OEM manufacturers allow businesses to innovate without limitations. Whether it's unique shapes, sizes, or finishes, the possibilities are virtually endless, enabling brands to differentiate themselves in the marketplace.

Conclusion

OEM tempered glass plays a pivotal role in modern manufacturing, contributing to safety, durability, and aesthetic appeal across various industries. As technology advances and innovative designs become more crucial, the demand for customized tempered glass solutions is likely to grow. By partnering with reliable OEMs, businesses can harness the power of tempered glass to enhance their product offerings and stay competitive in an ever-evolving market. The significance of OEM tempered glass cannot be understated—it's not just a material; it's a cornerstone of modern innovation.