When considering the purchase of 4mm float glass, understanding the pricing dynamics and the value proposition of this product is essential. As a tangible element of the modern building industry, 4mm float glass is a versatile material with applications ranging from residential windows to industrial projects. Here’s an in-depth analysis of the factors influencing its price, from production methods to market demand, offering an expert’s view on maximizing your investment.

Float glass production is a sophisticated process that synthesizes raw materials like silica sand, soda ash, and limestone at high temperatures to form a smooth, uniform sheet of glass. The float method, pioneered in the 1950s, involves the molten glass being floated on a bed of molten tin, ensuring a consistent thickness and flawless surface. This method not only ensures quality but also affects pricing by streamlining production costs and increasing output efficiency.

Global market conditions significantly impact the price of 4mm float glass. Variations in energy costs, fluctuations in raw material availability, and international trade policies can lead to cost variations. For instance, an increase in fuel prices will invariably raise transportation costs, thereby affecting the end price of 4mm float glass. Additionally, tariffs and trade restrictions in major glass-producing regions can disrupt supply chains, leading to price hikes.

Sustainability is an increasingly influential factor in the glass industry. The shift towards eco-friendly and energy-efficient materials has driven research into advancing glass production techniques, potentially altering cost structures. Low-emissivity (Low-E) coatings, which improve insulation properties, may add to initial costs but provide long-term energy savings, showcasing the glass's value beyond its price tag.

The demand for 4mm float glass is augmented by its versatile applications. It is used in everything from glazed windows to solar panels and even in defining aesthetic features of modern architecture. This broad application range generally maintains a steady demand, bolstering economic stability within the market and offering some degree of price predictability.

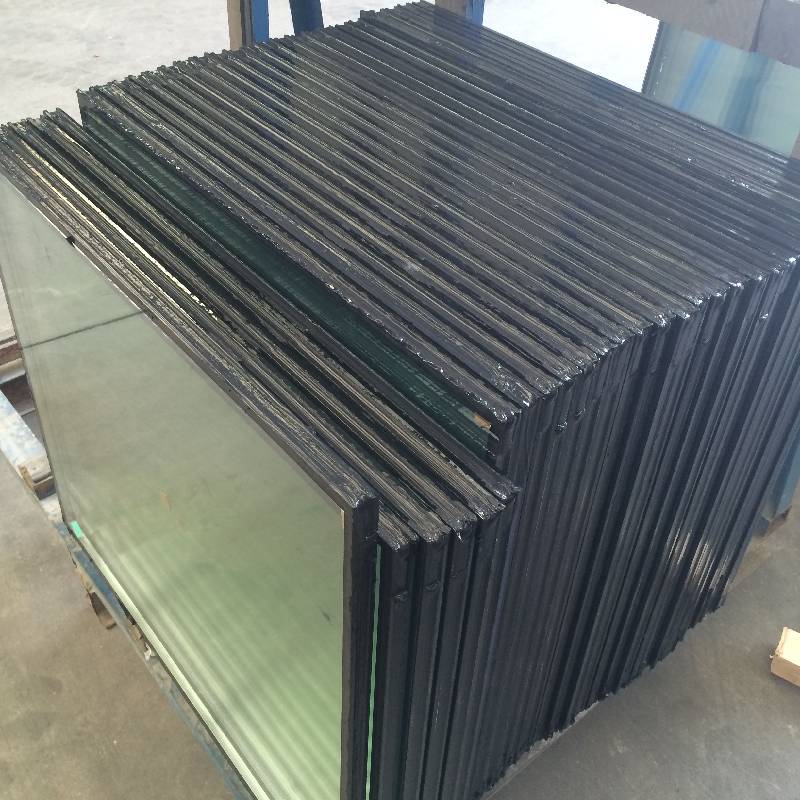

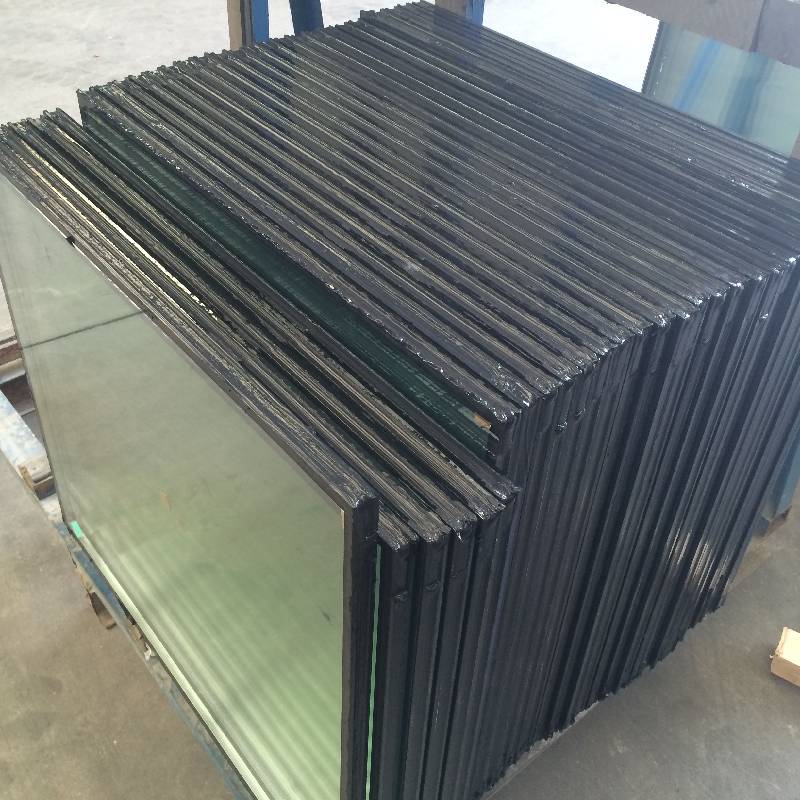

4mm float glass price

The expertise of suppliers and manufacturers also plays a pivotal role in pricing. Reputable suppliers with established manufacturing protocols and rigorous quality checks can command higher prices as they guarantee product consistency and reliability. This is crucial in industries where precision and quality control are non-negotiable, such as in the automotive or tech packaging sectors.

Purchasers can leverage market expertise and data-driven insights to make informed decisions. Keeping abreast of quarterly market reports, attending industry conferences, and engaging with industry thought leaders can offer a competitive edge. Furthermore, forming strategic alliances with suppliers through volume purchasing agreements or long-term purchasing contracts can result in favorable pricing adjustments.

Trustworthiness is a vital component when selecting a supplier for 4mm float glass. Verification of a supplier’s compliance with industry standards and their performance guarantees are vital. Suppliers committed to sustainability practices, quality management systems, and customer service excellence usually provide more reliable transactions, ensuring a level of trust and consistency in product delivery.

In conclusion, the price of 4mm float glass is shaped by diverse factors spanning production, market demands, and supplier reliability. By understanding these elements, businesses can make informed purchasing decisions that not only meet immediate needs but also align with long-term operational goals. Engaging with industry expertise, utilizing authoritative sources, and cultivating trust-based supplier relationships are strategies that can significantly enhance purchasing outcomes.