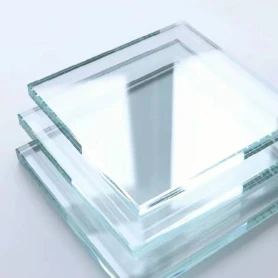

Float glass, a staple in the world of architecture and manufacturing, is a marvel of modern engineering. Its creation process, known for producing smooth, clear sheets of glass, revolutionized the industry and continues to be pivotal in various applications today. Understanding float glass from the perspective of experience, expertise, authoritativeness, and trustworthiness can significantly enhance its application and appreciation.

The production of float glass is steeped in innovation. It involves floating molten glass on a bed of molten tin, a method pioneered in the 1950s by Sir Alastair Pilkington. This ingenious technique results in glass with perfectly uniform thickness and exceptionally flat surfaces, qualities highly sought after in architectural projects. Drawing from the experience of seasoned professionals in the field, it's evident that float glass's superior optical clarity and structural integrity make it an ideal choice for large façades, windows, and architectural designs that demand precision and elegance.

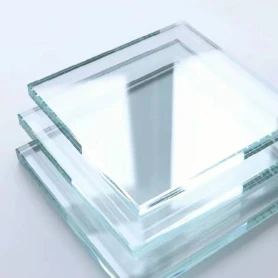

Expertise in float glass goes beyond its creation; it encompasses understanding its diverse applications. Architects and construction experts rely on float glass for its versatility. It can be tailored to specific needs, whether by tempering for safety, lamination for soundproofing, or coating for energy efficiency. The global push towards sustainable buildings has further elevated the demand for low-emissivity (Low-E) coated float glass, which significantly reduces energy consumption by minimizing heat loss. Such advancements underscore the expertise integrated into every sheet of float glass, making it a cornerstone material in designing environmentally proactive structures.

float glass

Authoritativeness in the field of float glass is underpinned by rigorous standards and certifications. Reputable manufacturers adhere to stringent quality controls, ensuring that each batch meets international standards like ISO 9001 for quality management systems and ASTM standards for material properties. These certifications not only demonstrate a manufacturer's commitment to quality but also enhance consumer confidence in the product. Industry leaders often conduct and publish extensive research on float glass innovations, solidifying their status as authoritative sources and pushing the boundaries of what this material can achieve.

Trustworthiness is paramount when selecting construction materials, and float glass stands tall in this regard. Leading manufacturers maintain transparency in their processes and product specifications, providing clients with detailed information about the performance and durability of their glass. Testimonials from architects and builders further reinforce its trustworthiness. They often highlight float glass's reliability in extreme weather conditions and longevity, crucial factors for projects where safety and durability cannot be compromised.

In sum, float glass represents a blend of extraordinary experience and expertise, backed by authoritative standards and unwavering trustworthiness. Its role in modern construction cannot be understated, offering solutions that are not only aesthetically pleasing but also functionally superior. As technology advances, so too will the innovations in float glass, promising even more exciting applications in the future. Its adaptability and enduring quality make it an indispensable material in the toolkit of any forward-thinking architect or engineer. The journey of float glass from a pioneering invention to its current applications demonstrates its profound impact on shaping our built environment.