Understanding Clear Float Glass Manufacturers A Comprehensive Overview

Clear float glass, renowned for its optical clarity and versatility, plays a critical role in various applications, from residential and commercial buildings to automotive manufacturing and decorative products. As the demand for high-quality glass continues to rise worldwide, clear float glass manufacturers have evolved to provide products that meet the needs of modern construction and design.

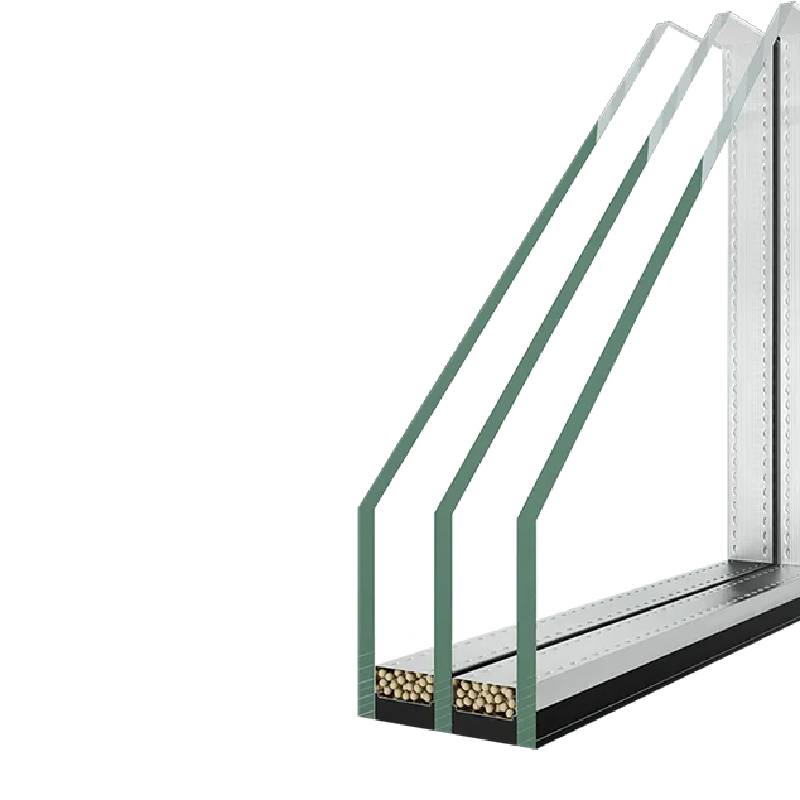

Float glass manufacturing is a process that entails melting raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten glass is then floated on a layer of molten tin, creating a flat, smooth surface on both sides. Once cooled and annealed, the glass maintains its clarity and uniform thickness, making it an ideal choice for windows, facades, mirrors, and more.

One of the key factors influencing the choice of a clear float glass manufacturer is their commitment to quality. Top manufacturers adhere to strict industry standards, ensuring their products are free from defects such as bubbles or distortions, which can compromise the aesthetic and functional qualities of the glass. Many companies also invest in cutting-edge technology to automate production processes, enhancing precision and efficiency while reducing waste.

Sustainability is another important consideration. As environmental concerns grow, clear float glass manufacturers are increasingly adopting eco-friendly practices. This includes employing recycled materials in their production processes and implementing energy-efficient technologies to minimize their carbon footprint. By prioritizing sustainability, manufacturers not only contribute to environmental conservation but also appeal to a growing market of eco-conscious consumers.

Furthermore, the customization offered by clear float glass manufacturers is noteworthy. With advancements in glass technology, manufacturers can provide various finishes, tints, and coatings that enhance the glass's performance, such as low-emissivity (Low-E) coatings that improve thermal insulation and reduce energy consumption in buildings. This customization allows architects and designers to achieve specific aesthetics and functional requirements in their projects.

Collaboration with manufacturers is vital for builders and designers looking to leverage the benefits of clear float glass. Establishing strong partnerships can lead to innovative solutions that enhance project outcomes. Many manufacturers offer expert guidance and insights based on years of experience, assisting clients in selecting the right types of glass for their specific applications.

In conclusion, clear float glass manufacturers play a vital role in the construction and design industries, combining quality, sustainability, and customization to meet the diverse needs of modern projects. As the market continues to evolve, these manufacturers will be pivotal in driving innovations that benefit both consumers and the environment. Whether for residential, commercial, or industrial purposes, choosing the right clear float glass manufacturer is essential to achieving the desired results in any project.