Understanding Float Glass Types A Comprehensive Overview

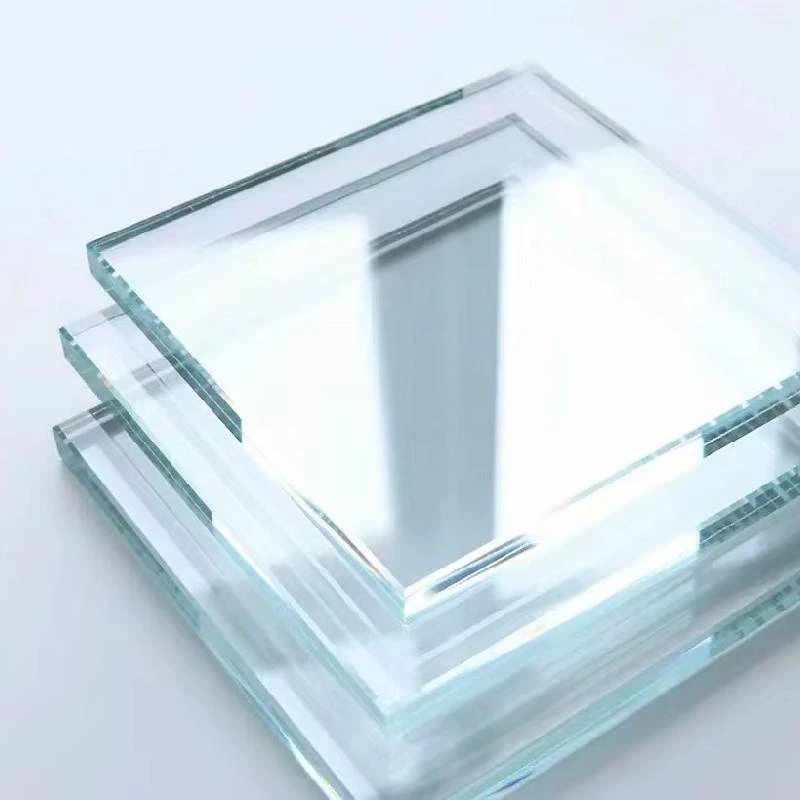

Float glass is a type of flat glass that is widely used in construction, automotive, and various industrial applications due to its exceptional clarity, smooth surfaces, and versatility. The manufacturing process of float glass, which involves floating molten glass on top of molten tin, results in a product with uniform thickness and minimal distortion. As demand for glass products continues to grow, understanding the different types of float glass becomes increasingly important. This article explores the various types of float glass, their characteristics, and applications.

1. Standard Float Glass

Standard float glass is the most common type, characterized by its clear, colorless appearance. It has a light transmission rate of around 90% and is mostly used in windows and facades of buildings. Due to its smooth surface, standard float glass is excellent for applications where optical clarity is important. However, it can be vulnerable to breakage and thermal stress, leading to a need for alternative types of glass in more demanding environments.

2. Low-E Glass

Low-emissivity (Low-E) glass is a specialized type of float glass that has a thin metallic coating applied to one side. This coating reflects heat and reduces UV rays without compromising light transmission. Low-E glass is highly effective in improving energy efficiency in buildings. It is commonly used in residential and commercial windows to reduce heating and cooling costs, thus contributing to sustainable architectural designs.

3. Tinted Float Glass

Tinted float glass is produced by adding colorants to the glass mixture during manufacturing, imparting a hue that can reduce glare and regulate light transmission. Common tints include bronze, grey, and green, which can also provide privacy to building occupants. Tinted glass is popular for commercial buildings, where control over sunlight and aesthetics is crucial. In addition, it can enhance the overall energy performance of a structure by decreasing solar heat gain.

Frosted float glass is created by sandblasting or acid etching standard float glass to create a translucent finish. This texture diffuses light while maintaining privacy, making it ideal for bathroom windows, conference rooms, and decorative applications. Frosted glass can also provide an aesthetic appeal, offering a modern look without compromising natural light.

5. Laminated Float Glass

Laminated float glass consists of two or more layers of glass bonded together by a layer of polyvinyl butyral (PVB). This type of glass is designed to enhance safety and security, as it holds together even when shattered, preventing dangerous shards from scattering. Laminated glass is widely used in automobile windshields and in areas where safety is a primary concern, such as in schools and public buildings.

6. Tempered Glass

Tempered float glass is heat-treated to increase its strength and thermal resistance. The tempering process involves heating the glass to high temperatures and then rapidly cooling it. This treatment makes tempered glass five to six times stronger than standard glass. When broken, it shatters into small, blunt pieces rather than sharp shards, reducing the risk of injury. It is used in applications like shower doors, glass doors, and facades, where strength and safety are critical.

7. Obscured Glass

Obscured float glass is ideal for applications requiring privacy while still allowing light to pass through. This type of glass is often used in residential settings, particularly for bathroom windows. It can be manufactured using various techniques, including frosted or etched patterns, that enhance aesthetic appeal while maintaining functionality.

Conclusion

Understanding the different types of float glass is essential for selecting the right product for specific applications. From standard float glass to specialized varieties like Low-E and laminated glass, each type offers unique benefits that cater to the diverse needs of the construction and manufacturing industries. As technology continues to advance, innovations in float glass production will likely unveil even more options, further expanding its applications in modern architecture and design. Whether for energy efficiency, safety, aesthetics, or privacy, float glass remains a critical material in our daily lives.