The Artistry of Patterned Glass A Journey Through the Factory

Nestled in the heart of an industrial district, the patterned glass factory stands as a testament to the intersection of art and industry

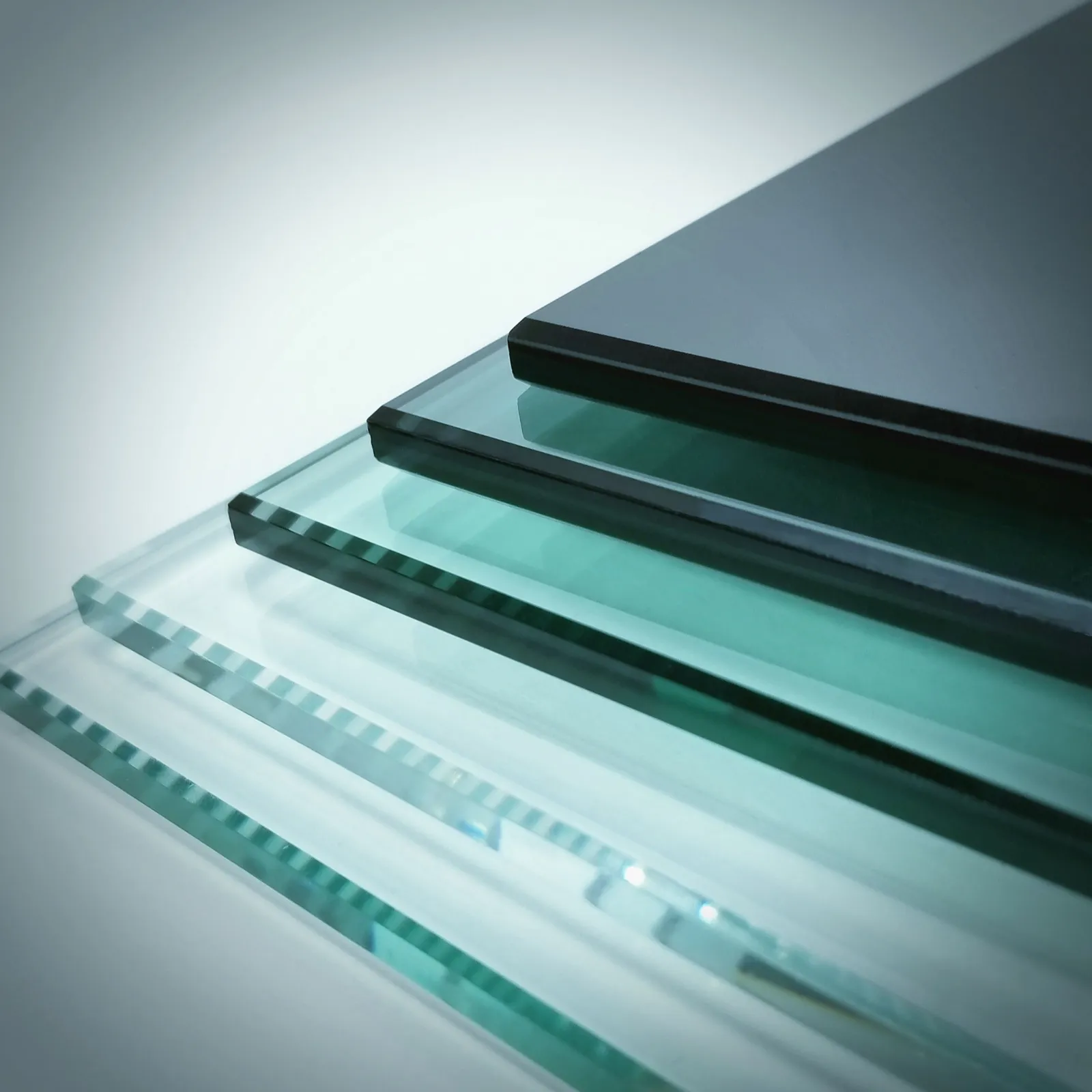

. As one approaches the facility, the sight of gleaming glass reflects the sun's rays, casting colorful patterns on the ground. This factory is not merely a production site; it is a sanctuary for creativity where skilled artisans transform raw materials into exquisite pieces of art.The journey begins in the raw materials section, where silica sand, soda ash, and limestone are carefully measured and blended. Each ingredient plays a crucial role in the glass-making process; the silica provides the basic structure, while soda ash lowers the melting point, and limestone adds stability. The precise combination ensures that the final product is not only beautiful but also durable.

Once the materials are mixed, they are placed into a massive furnace, heated to temperatures exceeding 1,700 degrees Celsius. This high-heat transformation turns the mixture into molten glass, a fascinating and captivating spectacle. Here, workers in protective gear monitor the process closely, ensuring that the molten glass achieves the perfect consistency before moving on to the shaping phase.

The shaping process is where the true artistry of the factory shines. Skilled glassblowers and mold makers work in tandem to create intricate patterns and designs. Using traditional techniques passed down through generations, they manipulate the molten glass, breathing life into it. The creation of patterned glass involves carefully crafted molds which apply textures and designs to the glass surface, ranging from elegant swirls to geometric shapes. Each piece is unique, telling its own story through the patterns that adorn its surface.

Once shaped, the glass must undergo a cooling process, known as annealing. This step is crucial, as it relieves internal stresses within the glass, ensuring its longevity. The annealing lehr, a long oven that cools the glass slowly and evenly, is filled with trays of newly formed pieces, each awaiting its turn to emerge as a polished product.

Finishing touches are applied after cooling. Craftsmen meticulously inspect each piece for quality, sanding edges, adding color, or applying a final polish to enhance brilliance. This attention to detail is what distinguishes patterned glass from ordinary glass; it is the harmony of creativity and craftsmanship.

The factory also embraces modern technology, adopting innovative techniques to expand its repertoire. Automated cutting machines work alongside artisans, allowing for precision and efficiency without sacrificing the human touch. Collaborations with designers and architects lead to the creation of bespoke items, from stunning glass facades for buildings to bespoke decorative pieces for homes.

In conclusion, the patterned glass factory is where tradition meets innovation. It is a place where artisans pour their heart and soul into every piece, ensuring that each creation is not just a product but a work of art. Visitors leave with a newfound appreciation for the beauty and complexity of patterned glass, recognizing that every shard carries a story, a reflection of the craftsmanship that brought it to life.