Tempered safety glass, commonly recognized for its strength and safety features, has become a vital material in various applications, including architecture, automotive, and even electronics. This specially treated form of glass is manufactured through a process of extreme heating and rapid cooling, which makes it significantly stronger than standard glass. Tempered safety glass is designed to endure both thermal stresses and mechanical impacts, making it an ideal choice for environments where safety and durability are paramount.

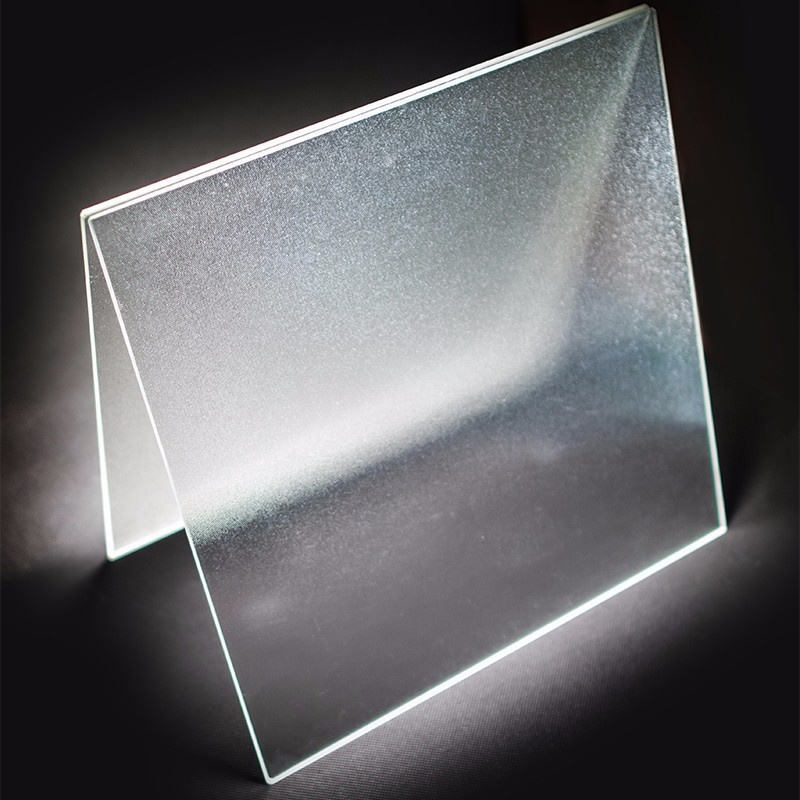

The process of creating tempered glass begins with the selection of high-quality raw materials. Once these materials are in place, the glass is heated to temperatures of around 600 degrees Celsius. This heating process alters the glass structure at a molecular level, improving its overall strength. After reaching the desired temperature, the glass is rapidly cooled. This rapid cooling is critical; it creates a state of compression on the surface of the glass while the interior remains under tension. This combination results in a material that can withstand impacts much better than regular glass; it is approximately four to five times stronger.

One of the significant advantages of tempered safety glass is its safety feature. When broken, tempered glass shatters into small, blunt pieces rather than sharp fragments. This characteristic greatly reduces the risk of injury, making it especially suitable for use in areas where human contact is likely, such as in buildings, vehicles, and shower enclosures. Manufacturers emphasize this safety characteristic in various applications, promoting tempered glass as a reliable choice for both residential and commercial projects.

In architecture, tempered safety glass serves multiple purposes

. It is often used for glass facades, skylights, and large windows, providing both aesthetic appeal and structural integrity. The glass can be treated with various tints or coatings to enhance energy efficiency, reduce glare, and block harmful UV rays. As sustainability becomes a crucial consideration in modern building practices, the energy-efficient capabilities of tempered glass are appealing to architects and builders alike.

In automotive applications, tempered glass is commonly used in side and rear windows. The strength of the glass ensures passenger safety, especially in the event of an accident. The shattering characteristic of tempered glass is beneficial here too, as it minimizes the likelihood of injury from sharp shards. In addition, advancements in glass technology have allowed for the integration of various features, such as tinting and sound insulation, further enhancing the driving experience.

Moreover, tempered safety glass is increasingly making its way into the world of electronics. From smartphone screens to tablet displays, the durability of tempered glass protects devices from scratches and impact. Manufacturers often treat the glass for additional resistance to breakage, ensuring that devices can withstand daily wear and tear.

In conclusion, tempered safety glass has established itself as an essential material across various industries. Its strength, safety features, and versatility make it an ideal choice for both practical and aesthetic applications. As technology advances, the uses for tempered glass will likely continue to expand, offering innovative solutions that prioritize safety and durability. Whether in architecture, automotive, or electronics, tempered safety glass proves to be a crucial element in enhancing modern living standards.