The Versatility of Tin Float Glass A Modern Architectural Marvel

Tin float glass, a significant innovation in glass manufacturing, has revolutionized the way architects and designers approach modern building projects. This type of glass is produced through a process known as floating, where molten glass is poured onto molten tin. The process not only results in smooth and flat surfaces but also enhances the glass's intrinsic properties, making it an ideal choice for a wide range of applications in contemporary architecture.

One of the most notable advantages of tin float glass is its exceptional clarity and transparency. The result of the float process is a glass that is vastly free of imperfections and distortions, allowing for optimal light transmission. This characteristic is particularly beneficial in both residential and commercial buildings, where natural light is highly coveted. By utilizing tin float glass in large windows and facades, architects can create bright and welcoming spaces that connect the indoors with the outdoors, fostering a sense of openness and tranquility.

Additionally, tin float glass offers remarkable durability and strength. The manufacturing process enhances its resistance to scratches, impacts, and environmental wear, making it suitable for high-traffic areas. This durability does not compromise its aesthetic appeal; in fact, the sleek, modern look of tin float glass can elevate the design of any structure. From skyscrapers to single-family homes, this type of glass is frequently employed in curtain walls, partitions, and glass doors, seamlessly integrating functionality with style.

Energy efficiency is another major benefit of tin float glass. Many manufacturers now produce variants with low-emissivity (low-E) coatings that reflect heat while allowing natural light to penetrate. This feature significantly reduces the need for artificial lighting and climate control, leading to a decrease in energy consumption. Consequently, buildings featuring tin float glass can achieve higher energy efficiency ratings, promoting sustainability and reducing their carbon footprint.

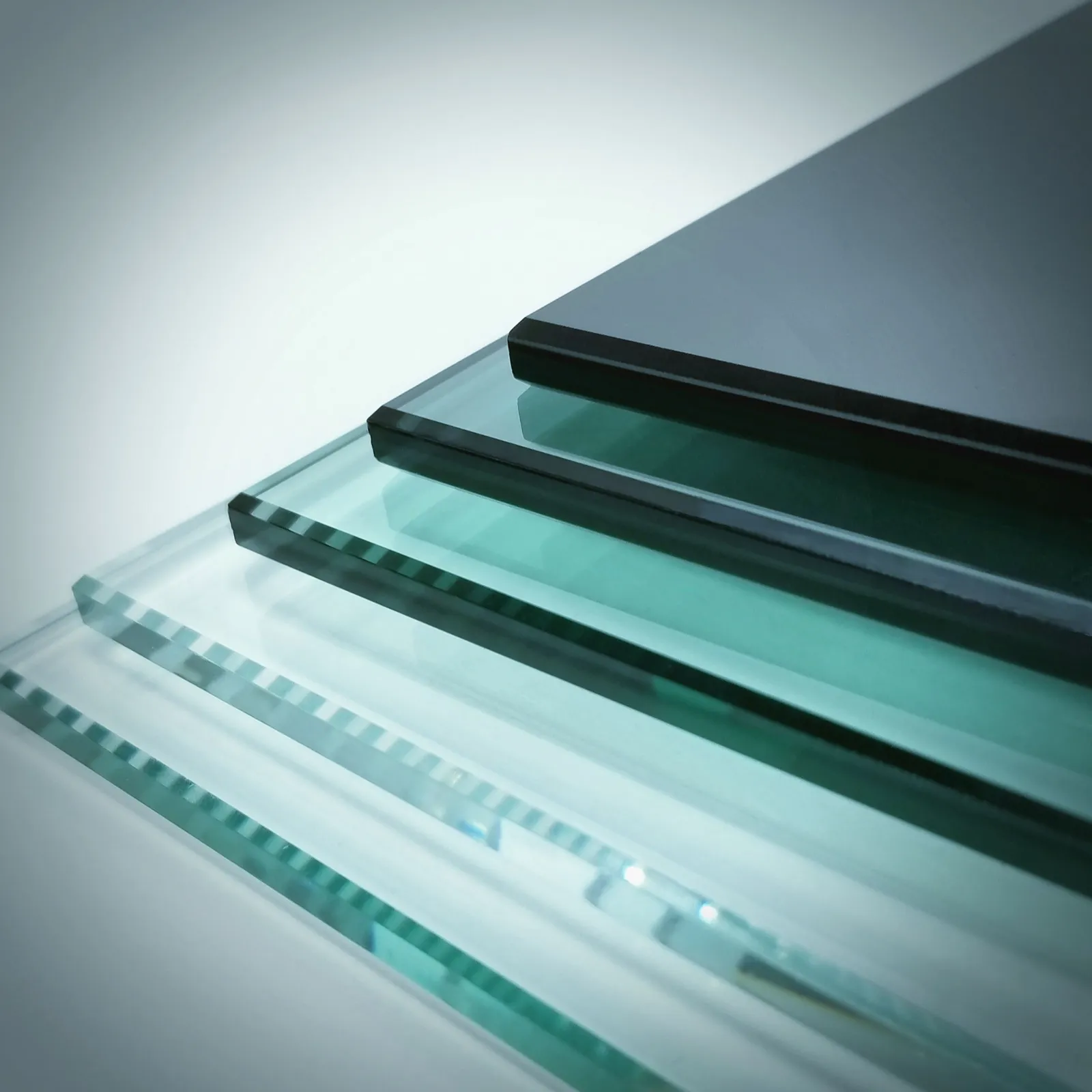

Moreover, the adaptability of tin float glass extends beyond its physical properties. It is available in various thicknesses and sizes, making it customizable for specific design needs. Whether used in sleek, minimalist designs or more intricate architectural forms, tin float glass can suit diverse aesthetic preferences. It can be treated with tints or films to control glare, enhance privacy, or even incorporate smart technology, such as switchable glass that changes transparency with the flick of a switch.

Finally, the ease of fabrication and installation associated with tin float glass cannot be overlooked. The manufacturing process ensures consistent quality, which simplifies the logistics from production to application. This efficiency helps architects and builders meet project timelines while maintaining high standards of workmanship.

In conclusion, tin float glass stands as a testament to modern engineering and design. Its remarkable qualities—clarity, durability, energy efficiency, adaptability, and ease of use—make it an essential material in contemporary architecture. As architects continue to push the boundaries of design, the use of tin float glass will undoubtedly play a pivotal role in shaping the skylines of the future, proving that beauty and functionality can coexist harmoniously in our built environment.