In a world where clarity defines quality, ultra clear glass has emerged as a premium solution for modern architectural, technological, and decorative applications. It is the ideal material for high-end buildings, display showcases, solar energy panels, and frameless facades where maximum light transmission and aesthetic purity are paramount. With its extraordinarily low iron content and precision manufacturing process, ultra clear glass elevates visual impact and performance well beyond what standard float glass can offer.

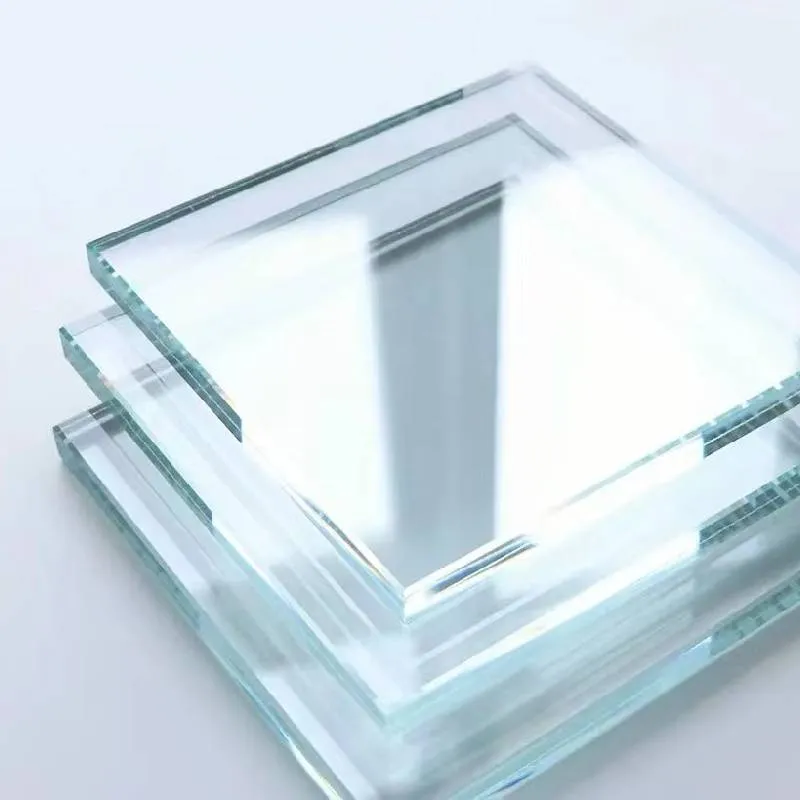

The most apparent distinction between ultra clear glass and ordinary float glass lies in its color neutrality and transparency. Standard glass often carries a greenish tint due to its natural iron oxide content. This becomes even more visible in thicker cuts, distorting both appearance and transmitted light. In contrast, ultra clear glass boasts an ultra-low iron content—typically less than 150 ppm—which significantly reduces this coloration, resulting in a truly neutral appearance even at greater thicknesses.

Thanks to its enhanced optical properties, ultra clear glass is ideal for applications like luxury storefronts, aquariums, solar panels, and museum showcases, where color distortion would compromise either function or aesthetic value. Whether used in double-glazing or laminated layers, ultra clear float glass maintains a consistent and vivid view, making it a superior alternative in any setting that values pristine transparency.

Creating high-performance ultra clear glass is a sophisticated process that begins with sourcing high-purity raw materials. The silica sand used in ultra clear glass production undergoes special refinement to remove impurities like ferric oxide. During float glass manufacturing, additional filtration systems and oxygen-controlled furnaces ensure no reintroduction of color-altering contaminants.

Precision annealing and surface polishing further improve optical clarity and flatness. As a result, the final ultra clear float glass product has a visible light transmittance of over 91%, compared to 83–87% for standard glass of similar thickness. These exceptional figures are not just numbers—they are what allow museums, hotels, and retail giants to present their spaces or products in the most vivid and undistorted form.

To ensure consistency, every batch of ultra clear glass is subject to automated light transmittance testing, haze measurement, and strain pattern inspections. These protocols make sure that buyers receive glass with unmatched brightness and uniformity, every time.

Transparency is more than just a selling point for ultra clear glass—it’s a measurable performance standard. High-end applications demand glass that can transmit as much visible light as possible while maintaining low reflectance and zero discoloration. For this reason, global buyers look for ultra clear glass with a minimum visible light transmittance of 91–92% at 4mm thickness.

Leading ultra clear glass manufacturers also ensure surface flatness deviation stays below 0.2mm/m and haze values under 0.3%, far surpassing regular float glass. These parameters are particularly important in architectural settings, such as curtain walls or interior partitions, where visual distortion or reflection warping can undermine the clean, minimalistic design intent.

For specialized use cases—such as photovoltaic panels or ultra-clear smart mirrors—select ultra clear glass grades even support anti-reflective or low-E coatings without compromising base clarity.

When considering ultra clear glass price, it's important to measure the cost in terms of value and longevity rather than just material expense. While ultra clear glass carries a higher price tag than conventional glass, the benefits in light transmission, durability, and design impact far outweigh the difference in cost.

Buyers across hospitality, retail, and real estate sectors view ultra clear glass as an investment in product presentation, property value, and user experience. It reduces the need for artificial lighting, enhances color fidelity for displayed objects, and adds an unmistakable level of luxury to any space.

Moreover, many ultra clear glass manufacturers offer additional value-added services such as custom cutting, tempering, laminated variants, UV control coatings, and edge finishing—all of which contribute to more efficient installation and longer life cycles.

Today’s architects and designers demand precision, and ultra clear float glass answers the call with unparalleled purity and structural versatility. Its ultra-flat surface makes it ideal for frameless designs, large-format facades, and digital displays that require distortion-free viewing angles.

What truly makes ultra clear float glass stand out is how it adapts to both aesthetic and functional goals. It provides an open, clean feel in modern interiors while allowing unobstructed visibility in exterior applications such as skywalks, greenhouses, and high-rise balconies. Its ability to transmit natural daylight without the green hue typical of standard glass creates a brighter, more inviting environment.

By choosing ultra clear glass from a reputable ultra clear glass manufacturer, clients unlock the full potential of modern glass technology, all while ensuring compliance with safety, UV, and optical performance standards.

Ultra clear glass has significantly lower iron content, eliminating the greenish tint and allowing over 91% light transmittance, compared to 83–87% in regular float glass.

Ultra clear glass is manufactured using ultra-pure silica sand and advanced filtration and float processes, ensuring minimal impurities and maximum optical clarity.

Top-grade ultra clear glass features visible light transmittance above 91% and haze levels below 0.3%, with strict quality control on flatness and surface uniformity.

Ultra clear float glass provides distortion-free views, high brightness, and structural integrity, making it perfect for frameless facades, partitions, and display applications.

Yes, the slightly higher ultra clear glass price is justified by its superior performance, longevity, and ability to enhance space value and visual impact.