In the rapidly evolving world of glass technology, 3mm float glass stands out as a remarkable product offering a blend of aesthetic appeal, functionality, and durability. As a thin, flat, and clear sheet of glass, 3mm float glass is produced through the float process, whereby molten glass is floated on a bed of molten tin. This unique production method endows the glass with a uniform thickness and a flawless surface, making it an ideal choice for a wide range of applications across different industries.

One of the primary applications of 3mm float glass is in the realm of interior design and architecture. Its sleek and minimalist appearance is highly sought after in modern interior spaces. It is often used for decorative elements, such as tabletops, cabinet doors, and shelving, providing a visually appealing and contemporary look. For architects and designers, 3mm float glass offers versatility in design without compromising on the integrity of the structure. Its thinness contributes to the creation of elegant and refined spaces, allowing for more creative freedom when it comes to designing open and light-filled environments.

From a functional standpoint, 3mm float glass is well-regarded for its optical clarity and light transmission properties. These characteristics make it a popular choice for applications where unobstructed visibility is crucial. For instance, it is an excellent material for picture frames, providing a clear view of the enclosed artwork or photographs without distorting colors or details. Similarly, in the automotive industry, 3mm float glass is used in vehicle windows and windshields, ensuring safety while delivering optimal visibility for drivers and passengers.

Moreover, the strength-to-weight ratio of 3mm float glass is exceptional. Despite its relatively thin profile, it offers considerable strength and resistance to thermal expansion, making it suitable for various temperature-controlled environments. Its ability to withstand temperature variations without cracking or breaking ensures that it is a reliable material for both indoor and outdoor applications. This property is particularly advantageous in conservatories or greenhouses, where temperature control and light transmission are vital for plant growth.

Another notable application of 3mm float glass is in the electronics industry. Its precision and smoothness are critical for the production of high-quality screens and displays. As technology advances, the demand for thinner, lighter, and more efficient displays increases, making 3mm float glass an invaluable component in the manufacturing of electronic devices such as smartphones, tablets, and laptops. The glass serves as a protective layer over the delicate electronic components, safeguarding them from dust, moisture, and scratches, all while allowing users to interact seamlessly with their devices.

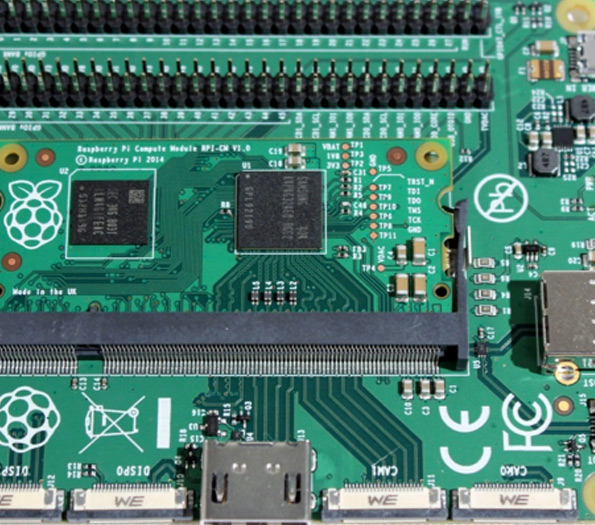

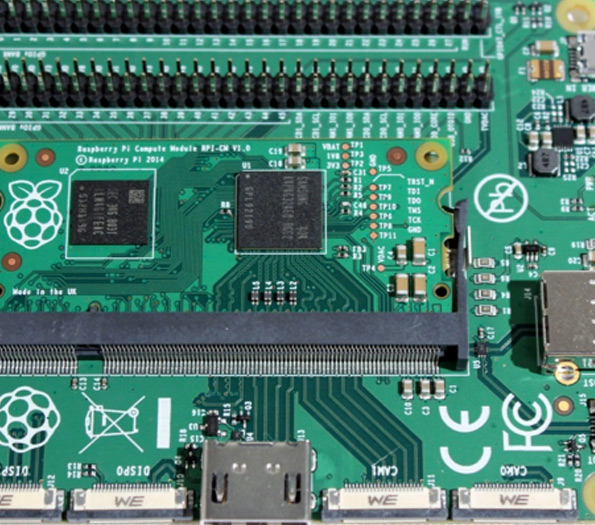

3mm float glass

The production of 3mm float glass also highlights its commitment to quality and sustainability. Manufacturers adhere to stringent quality control measures, ensuring that each sheet of glass meets the highest standards of clarity, durability, and safety. Furthermore,

the float glass process is more environmentally friendly compared to other glass-making methods. It requires less energy, produces minimal waste, and supports recycling efforts within the industry. By choosing 3mm float glass, consumers and businesses are not only investing in a superior product but also contributing to the global push towards sustainable and eco-friendly manufacturing practices.

In terms of expertise, the manufacturing of 3mm float glass is a highly specialized field requiring skilled professionals with an in-depth understanding of glass chemistry and engineering. The production process is both an art and a science, involving precise control over temperature, timing, and atmospheric conditions. This expertise ensures that the end product is of exceptional quality, characterized by its uniform thickness and smooth finish. Moreover, ongoing research and development efforts within the industry are continually improving the properties and applications of 3mm float glass, reaffirming its place as a leading material in the glass market.

Authorities, such as the International Commission on Glass and various national standards organizations, govern the production and application of float glass, including the 3mm variant. These organizations establish guidelines and standards that ensure the safety, reliability, and environmental impact of float glass products. Compliance with such standards not only enhances trust among consumers and industry professionals but also reinforces the credibility and authority of manufacturers who adhere to these rigorous requirements.

In conclusion, 3mm float glass is an outstanding material celebrated for its excellent optical properties, strength, versatility, and sustainable production. Its applications span numerous industries, from interior design and architecture to electronics and automotive engineering, proving its indispensability in modern technology and design. For those seeking a high-quality glass product that marries functionality with aesthetics, 3mm float glass remains an unparalleled choice.