Aluminum Alloy Mirrors A Reflection of Innovation

Aluminum alloy mirrors are at the forefront of technological advancements in reflective surfaces, merging the lightweight properties of aluminum with the strength and versatility of alloy formulations. These mirrors have found applications across various industries, including aerospace, automotive, solar energy, and decorative arts. Their unique attributes make them an attractive alternative to traditional glass mirrors, offering numerous advantages that cater to modern needs.

One of the primary benefits of aluminum alloy mirrors is their lightweight nature. Traditional glass mirrors can be cumbersome, making them less suitable for applications where weight is a critical factor, such as in aircraft or vehicles. In contrast, aluminum alloy mirrors are significantly lighter while maintaining structural integrity. This weight reduction can lead to fuel efficiency improvements in transportation, as well as ease of handling and installation.

Corrosion resistance is another standout feature of aluminum alloy mirrors. Aluminum, when alloyed with other metals like magnesium or silicon, becomes inherently resistant to oxidation. This resistance allows mirrors to maintain their reflective quality over time, even when exposed to harsh environmental conditions. As a result, they are ideal for outdoor applications and industries such as solar energy, where durability is paramount. Companies working with solar collectors often utilize aluminum alloy mirrors to reflect sunlight efficiently while ensuring longevity.

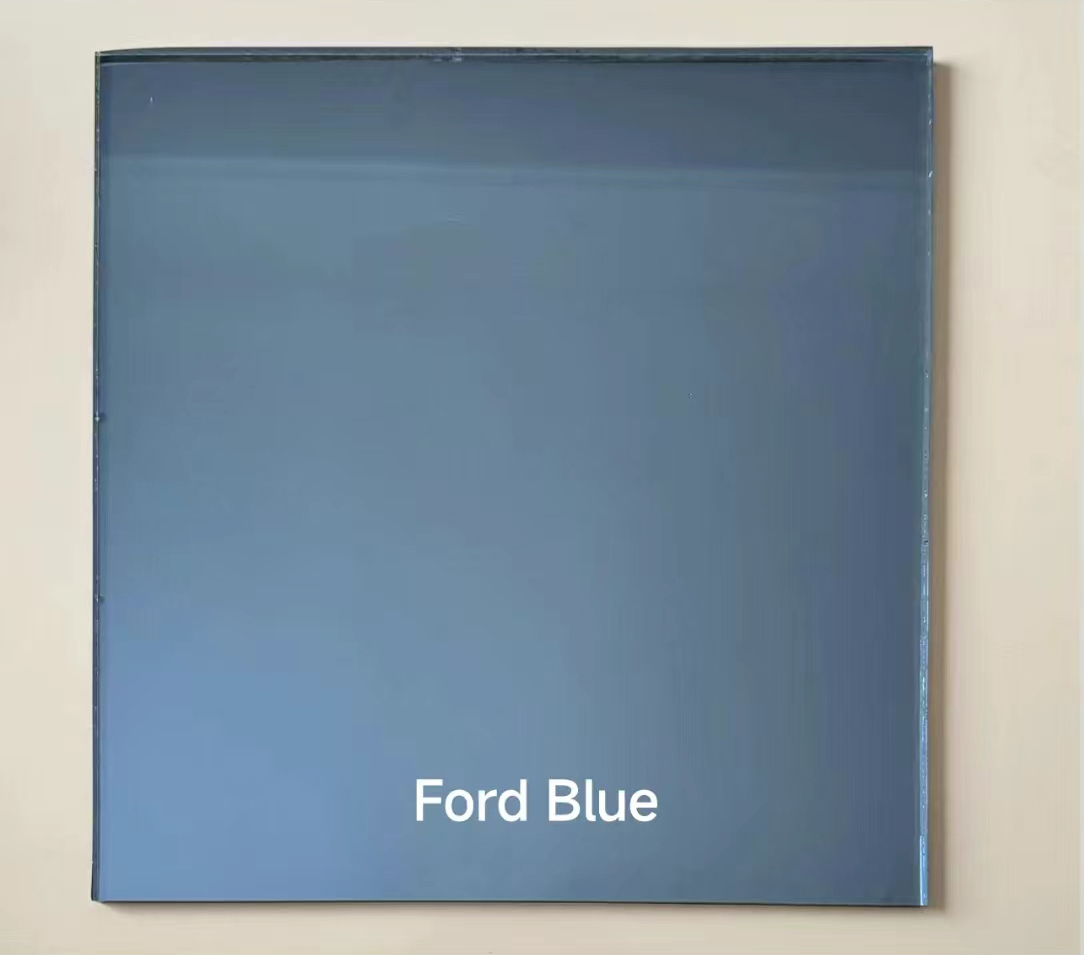

The versatility in design and manufacturing processes further enhances the appeal of aluminum alloy mirrors. These mirrors can be produced in various shapes and sizes, accommodating diverse requirements. Advanced manufacturing techniques such as CNC machining and precision casting allow for highly intricate designs, which can be tailored to specific applications. Additionally, aluminum can be easily anodized or coated, providing options for aesthetic and functional finishes.

Aluminum alloy mirrors also exhibit superior thermal conductivity. This property is particularly advantageous in applications where temperature regulation is critical. For instance, in solar power systems, maintaining optimal temperatures enhances the efficiency of energy capture. The ability to reflect and dissipate heat effectively makes aluminum alloy mirrors a preferred choice in thermal management.

Moreover, these mirrors contribute to sustainability efforts. Aluminum is one of the most recyclable materials available, with the potential to be recycled indefinitely without degradation of its properties. This eco-friendly aspect is gaining importance as industries strive to reduce their carbon footprint and promote responsible resource management. By utilizing aluminum alloy mirrors, companies can support sustainability initiatives while enjoying the functional benefits these mirrors offer.

In the decorative arts, aluminum alloy mirrors are gaining popularity for their contemporary aesthetic appeal. Designers appreciate the sleek, modern look these mirrors provide, which can enhance interior spaces while maintaining an air of sophistication. With the ability to customize finishes and shapes, aluminum alloy mirrors can serve as striking focal points in homes and commercial settings.

In conclusion, aluminum alloy mirrors represent a harmonious blend of innovation, functionality, and sustainability. Their lightweight, corrosion-resistant attributes, combined with versatility in design and thermal management capabilities, make them an ideal choice for a multitude of applications. As industries continue to prioritize efficiency and environmental responsibility, the use of aluminum alloy mirrors is poised to expand, reflecting a future where innovation resonates across various realms.