Understanding Annealed Float Glass Properties, Production, and Applications

Annealed float glass is a fundamental material widely used in the construction, automotive, and decorative industries. Understanding its properties, production processes, and various applications can provide valuable insights into its significance in modern society.

What is Annealed Float Glass?

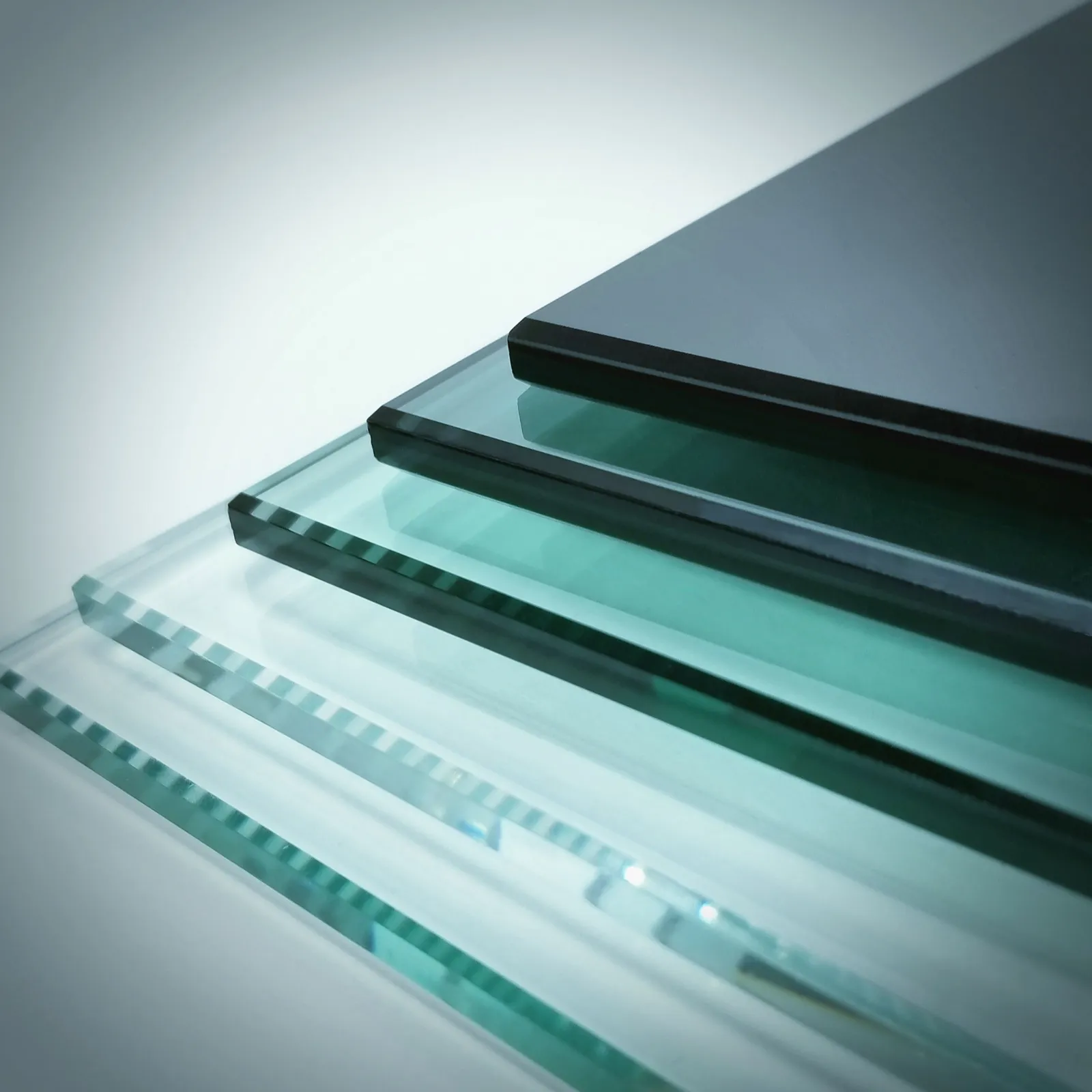

Annealed float glass is produced through the float glass process, which involves melting raw materials such as silica sand, soda ash, and limestone in a furnace to create molten glass. This molten glass is then poured onto a bed of molten tin, where it spreads out and forms a flat, uniform sheet. The term float refers to this process, as the glass floats on the surface of the molten tin, allowing for a smooth and even finish.

Once the glass has formed, it undergoes an annealing process, where it is slowly cooled in a controlled environment. This gradual cooling is critical, as it helps relieve internal stresses that may have developed during the heating phase. The result is a durable, flat glass product that exhibits excellent optical clarity and is suitable for various applications.

Properties of Annealed Float Glass

Annealed float glass is known for its numerous favorable properties, making it a popular choice across different industries. Some of these properties include

1. Clarity and Transparency Annealed float glass provides high levels of optical clarity, making it ideal for applications where visibility is crucial, such as windows and display cases.

2. Flatness The float process results in a remarkably flat surface, which is essential for applications requiring precision and aesthetics.

3. Chemical Resistance The glass is resistant to many chemicals, making it suitable for use in various environments without degrading its properties.

5. Cost-Effectiveness Compared to other glass processing techniques, the float process is relatively cost-effective, allowing for mass production at reasonable prices.

Applications of Annealed Float Glass

Given its desirable properties, annealed float glass finds use in a myriad of applications

1. Architectural Applications It is extensively used in building facades, windows, and doors. Its aesthetic appeal and ability to be treated with coatings for UV protection or energy efficiency enhance its functionality in modern architecture.

2. Automotive Glass Annealed float glass is used in producing various vehicle windows due to its clarity and flatness. While tougher glass options like tempered glass are often used for safety, annealed float glass can serve effectively in less critical applications.

3. Interior Design The glass is popular in interior design elements such as mirrors, tabletops, and decorative panels, contributing to modern aesthetics while being functional.

4. Display Cases Retail environments utilize annealed float glass for display cases, ensuring that products are showcased clearly without distortion.

5. Industrial Uses It is also used in various industrial applications, including partitions and protective barriers.

Conclusion

In summary, annealed float glass is a versatile and essential material characterized by its clarity, flatness, and workability. Its production through the float process and subsequent annealing creates a product with various beneficial properties that make it suitable for a wide range of applications. From architectural uses to automotive components and decorative elements, annealed float glass continues to play a vital role in modern life, embodying functionality and aesthetic appeal. As technology advances, the potential for innovative applications of annealed float glass will likely expand, highlighting its enduring significance in multiple industries.