Glass is one of the most versatile materials used in modern manufacturing, from household items to complex industrial applications. Whether it’s for windows, containers, or intricate designs, glass is integral to many industries. Glass manufacturers play a pivotal role in producing this essential material, while glass suppliers ensure that the material reaches the market in a variety of forms. In this article, we’ll explore the role of glass manufacturers, glass suppliers, glass factories, and glass wholesale manufacturers, highlighting their significance in the glass industry and their contributions to various sectors.

Glass manufacturers are the key players in the creation of glass products. They are responsible for turning raw materials like silica sand, soda ash, and limestone into the glass that is used in a wide range of applications. These manufacturers use specialized techniques such as melting, molding, and blowing to form glass into everything from common household products to sophisticated, high-performance materials used in industries like construction, automotive, and electronics.

The process starts in a high-temperature furnace where raw materials are melted into a liquid. Once molten, the glass can be shaped into molds or blown into specific shapes depending on the end product. The precision required in this stage is essential to ensure the glass has the desired properties, such as clarity, strength, and flexibility. Many glass manufacturers also incorporate cutting-edge technology to ensure their products meet stringent industry standards.

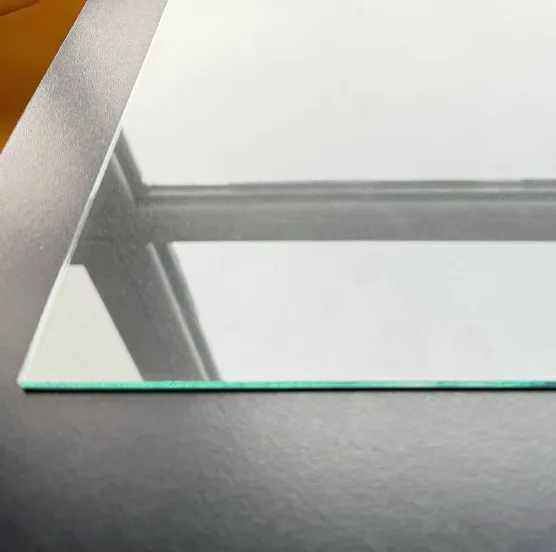

In addition to producing standard glass types, many glass manufacturers are also engaged in the creation of specialized glass. For example, in the automotive industry, manufacturers produce tempered glass, which is strengthened to prevent breakage, and laminated glass, which enhances safety by preventing shattering. In the electronics industry, manufacturers produce thin, lightweight glass for use in devices like smartphones and tablets. Glass manufacturers thus meet the demands of various industries, ensuring their products are suitable for a multitude of applications.

While glass manufacturers are responsible for producing glass products, glass suppliers are the vital link that connects manufacturers with the market. Glass suppliers are businesses that purchase glass from manufacturers and then sell it to customers such as wholesalers, retailers, or end consumers. Suppliers often hold large inventories of various types of glass, from simple window glass to specialized types for the automotive or construction industries.

A glass supplier not only ensures a steady supply of glass products to the market but also offers valuable services such as transportation, packaging, and delivery. For large-scale orders, a glass supplier may provide tailored solutions for specific needs, such as custom cutting or design services. This can be particularly useful for industries like construction, where precise dimensions and specifications are required.

Additionally, glass suppliers are often experts in sourcing a variety of glass types and grades. They can provide advice and recommendations to customers based on their needs, ensuring that they receive the correct type of glass for their projects. Whether it's tempered, laminated, or energy-efficient glass, glass suppliers play a crucial role in meeting the diverse needs of the market.

A glass factory is the place where the manufacturing process comes to life. This is where raw materials are transformed into the finished glass products that are used in industries across the world. In a glass factory, teams of skilled workers operate high-tech machinery and furnaces that melt, mold, and shape glass into a wide array of products.

The process in a glass factory begins with the preparation of raw materials, followed by melting them in specialized furnaces. Once the glass is in a molten state, it can be formed into a variety of shapes, such as flat sheets for windows, containers for food and beverages, or even intricate designs for decorative pieces. The factory also ensures that the glass undergoes the necessary cooling processes to avoid cracks or other defects.

One of the key advantages of a glass factory is the ability to mass-produce glass products at scale. Large factories are designed to produce significant quantities of glass, making it an efficient solution for both local and international markets. As demand for glass grows, glass factories are able to expand their operations and introduce new techniques to meet evolving industry standards.

Moreover, glass factories are constantly innovating to improve the quality and functionality of the glass produced. For example, many factories now use advanced technologies like automated inspection systems to detect imperfections in the glass before it is shipped out, ensuring high-quality standards are met for every order.

Glass wholesale manufacturers are specialized companies that focus on producing large quantities of glass for distribution to wholesalers, retailers, or direct customers in bulk. These manufacturers often cater to large-scale projects, such as the construction of commercial buildings, infrastructure, or manufacturing plants, where large quantities of glass are required.

Working with glass wholesale manufacturers has several advantages, including cost savings through bulk orders and the ability to customize orders to meet specific project requirements. These manufacturers typically offer a range of glass types, such as tempered, laminated, or insulated glass, and can work closely with clients to ensure the glass meets the necessary specifications for each application.

Moreover, glass wholesale manufacturers often provide flexible production schedules to meet tight deadlines. In industries where time is of the essence, having a reliable wholesale manufacturer ensures that glass is delivered on time, preventing delays in construction or manufacturing projects. Additionally, these manufacturers may offer additional services, such as cutting, shaping, and treating the glass, allowing for a comprehensive solution to bulk orders.

By working with glass wholesale manufacturers, businesses can streamline their supply chain, ensuring that they have a steady and reliable source of glass for large projects. These manufacturers are equipped to handle large orders and provide consistent quality, making them an essential part of the glass industry.

Glass manufacturers produce a wide variety of glass types, including tempered glass, laminated glass, and energy-efficient glass, for use in industries such as construction, automotive, and electronics.

Glass suppliers ensure quality by sourcing glass from trusted glass manufacturers, conducting rigorous inspections, and offering customized solutions to meet client specifications.

A glass factory is the facility where glass is produced, while glass manufacturers refers to the companies or businesses that oversee the production process and create the glass products.

Buying from glass wholesale manufacturers offers the advantage of bulk pricing, customization options, and timely delivery for large-scale projects.

Working with a glass supplier ensures reliable access to various glass products, transportation, and additional services like custom cutting or packaging for your project needs.