In modern architecture and advanced industrial applications, the choice of glazing materials significantly impacts energy efficiency, aesthetic appeal, and occupant comfort. Among the myriad options, reflective glass stands out for its exceptional performance characteristics. It is a type of glass that has been treated with a metallic coating to reflect a significant portion of solar radiation, thereby reducing heat gain within buildings and minimizing glare. Understanding the various types of reflective glass is crucial for architects, designers, and engineers aiming to specify the most suitable material for their projects.

The global glass industry, particularly the segment of high-performance architectural glass, is experiencing robust growth. Driven by increasing urbanization, stricter energy efficiency regulations worldwide, and a growing emphasis on sustainable building practices, the demand for specialized glass products like reflective glass is accelerating. According to recent market reports, the global smart glass market, which includes reflective and low-emissivity (Low-E) coatings, is projected to reach over USD 10 billion by 2028, with a Compound Annual Growth Rate (CAGR) exceeding 15%. This surge is largely attributed to the increasing adoption of green building initiatives and the need for energy-efficient solutions in both commercial and residential sectors. The evolving landscape also highlights a shift towards multi-functional glass, combining reflective properties with other features like self-cleaning, noise reduction, and enhanced security.

Reflective glass transforming modern building facades.

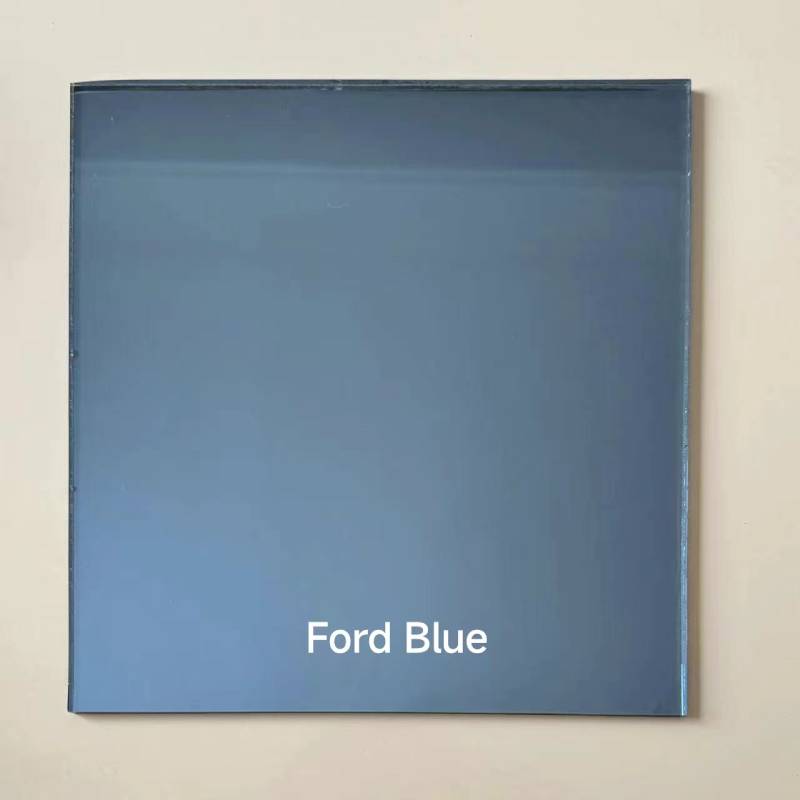

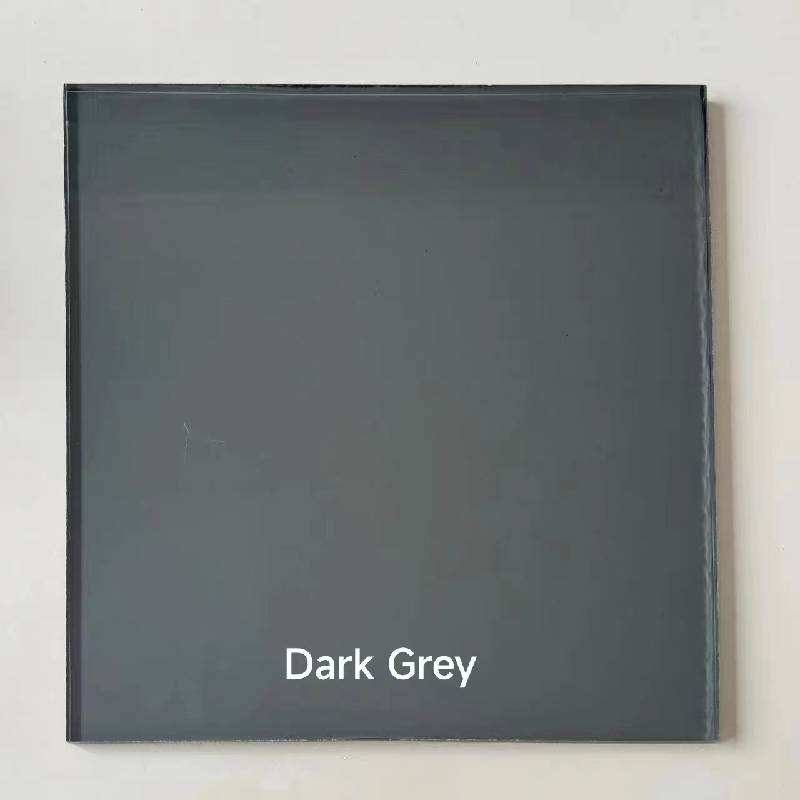

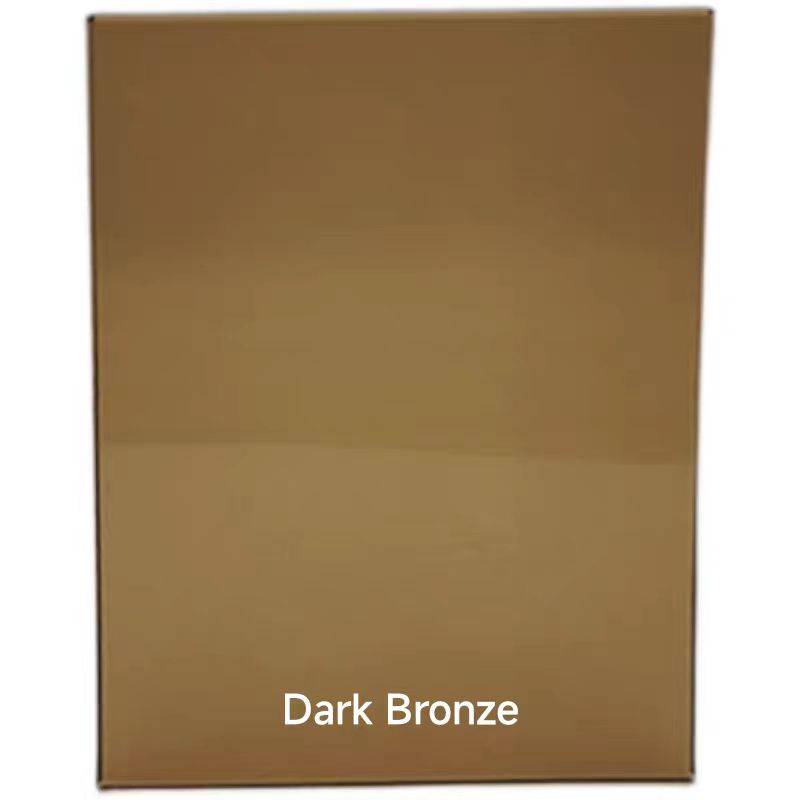

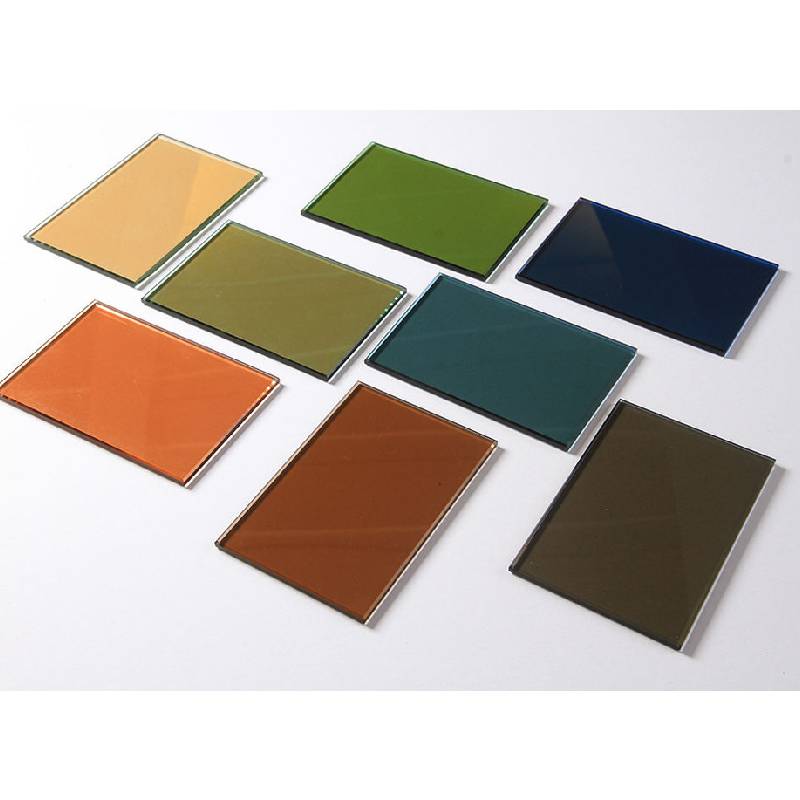

Technological advancements in coating techniques are continually expanding the capabilities and types of reflective glass available. Innovations in vacuum sputtering and chemical vapor deposition (CVD) have enabled the creation of coatings with precise spectral selectivity, allowing visible light to pass through while reflecting unwanted infrared and ultraviolet radiation. This allows for optimized natural light utilization without the adverse effects of heat buildup or excessive glare. The market is also seeing an increase in demand for aesthetically versatile reflective glass, offering a wide range of colors and finishes to meet diverse architectural visions.

Reflective glass is fundamentally defined by its ability to reflect solar energy, a property achieved through specialized metallic or metal oxide coatings. These coatings are incredibly thin, often measured in nanometers, and are applied to a base of float glass. The performance of reflective glass is quantified by several key technical parameters:

Variations in reflective glass coatings for diverse performance and aesthetics.

To illustrate the differences in performance, here's a comparative table based on typical industry data for different types of reflective glass. These values can vary based on thickness, specific coating, and IGU configuration. Data sourced from typical product specifications and industry standards like ASTM E903 for solar optical properties.

| Glass Type (6mm) | Visible Light Transmittance (VLT %) | Visible Light Reflectance (VLR %) (Exterior) | Solar Heat Gain Coefficient (SHGC) | U-value (W/m²K) (Single Glazing) | Application Suitability |

|---|---|---|---|---|---|

| Clear Float Glass (Reference) | 90 | 8 | 0.87 | 5.7 | Standard glazing, low solar control |

| Hard Coat (Pyrolytic) Reflective (e.g., Bronze) | 40-50 | 15-25 | 0.35-0.45 | 5.0-5.5 | Single glazing, spandrel, moderate solar control |

| Soft Coat (Sputtered) Reflective (e.g., Silver/Blue) | 15-30 | 25-45 | 0.20-0.30 | 1.5-2.0 (in IGU) | High-performance facades, severe solar exposure |

| Semi Reflective Glass (e.g., Light Grey) | 50-65 | 10-20 | 0.45-0.55 | 5.0-5.3 | Balanced light & heat, moderate privacy |

| Non Glare Glass / Anti-Reflective Glass | >98 | ~0.85 | ~5.6 | Display cases, storefronts, maximum transparency |

The data clearly illustrates how different types of reflective glass offer a wide spectrum of performance characteristics. For instance, soft coat reflective glass, when used in an Insulated Glass Unit (IGU), dramatically lowers the U-value and SHGC compared to basic float glass, signifying superior thermal insulation and solar heat rejection. This directly translates into significant energy savings for heating and cooling.

The creation of high-quality Reflective Glass is a sophisticated process that combines advanced material science with precise engineering. The base material is typically high-quality float glass, produced by floating molten glass on a bed of molten tin to create a perfectly flat and uniform sheet. Once the base glass is formed, the reflective coating is applied using one of two primary methods, depending on the desired types of reflective glass:

High-quality raw materials (silica sand, soda ash, limestone) are melted in a furnace, then poured onto a bath of molten tin. The glass floats and spreads to form a flat, uniform ribbon as it cools.

The cooled float glass sheets are thoroughly cleaned and dried to remove any impurities or dust, ensuring optimal adhesion and quality of the subsequent coating layers.

The cleaned glass sheets are transferred into a large vacuum chamber. The chamber is then evacuated to create an ultra-high vacuum environment, essential for the sputtering process.

Within the vacuum, various metallic or metal oxide targets (e.g., silver, titanium, nickel-chromium) are bombarded with energized argon ions. This dislodges atoms from the targets, which then deposit uniformly onto the glass surface, forming extremely thin, multi-layered reflective coatings. The number and composition of layers dictate the specific optical and thermal properties, differentiating types of reflective glass.

After coating, each sheet undergoes rigorous inspection for uniformity, adhesion, optical performance (VLT, SHGC, Reflectance), and visual defects. This ensures compliance with international standards like ISO 9001 and ASTM E903.

The edges of the coated glass, which may have irregularities from handling or coating start/stop, are removed. The glass is then cut to precise dimensions as per client specifications.

Finished Reflective Glass sheets are carefully packaged to prevent damage during transport, typically on A-frames or in crates, ready for delivery to project sites or further processing into IGUs.

(Note: For Pyrolytic (Hard Coat) Reflective Glass, step 4 (coating application) occurs during the float glass production on the tin bath, making it an "on-line" process.)

Precision manufacturing of reflective glass coatings.

Our Reflective Glass adheres to stringent international quality and performance standards.

While the query mentions petrochemical, metallurgy, water supply/drainage, for glass, the primary applicable industries are:

In typical application scenarios, especially in large-scale commercial buildings, the energy-saving benefits of reflective glass are profound. By significantly reducing solar heat gain, it decreases the demand for air conditioning, leading to substantial reductions in electricity consumption and operational costs. For instance, a building using high-performance reflective glass with an SHGC of 0.25 can realize up to 30-40% savings in cooling energy compared to standard clear glazing in hot climates. Furthermore, the anti-corrosion properties of certain robust coatings ensure longevity and stable performance even in challenging environmental conditions, enhancing the overall durability of the facade.

The versatility of types of reflective glass allows for their widespread adoption across a multitude of applications. From enhancing the aesthetic appeal of a skyscraper to optimizing the indoor climate of a residential home, its benefits are tangible and measurable.

Reflective glass enhancing the energy efficiency of commercial structures.

Our commitment to quality and customer satisfaction is reflected in our project successes and client testimonials. For a recent project, a 30-story commercial tower in a sun-drenched region, we supplied over 50,000 square meters of high-performance soft coat Reflective Glass (SHGC 0.23, VLT 25%).

Case Study: Metropolis Tower (Hypothetical)

Location: Desert Climate City

Challenge: Minimize extreme solar heat gain and reduce reliance on large HVAC systems, while maintaining a modern, sophisticated aesthetic.

Solution: Specified a custom semi reflective glass with a specific VLT and high solar reflection, integrated into an Insulated Glass Unit (IGU) with a Low-E coating on the inner pane. This dual-action approach maximized thermal performance.

Outcome: The building achieved a LEED Gold certification, with the client reporting a 35% reduction in annual cooling energy consumption compared to initial projections with standard glazing. Occupant feedback consistently highlighted the comfortable indoor temperatures and significantly reduced glare, even during peak sun hours. "TP Top Glass's solution not only met our stringent performance requirements but also delivered the aesthetic we envisioned for a landmark building," commented the lead architect.

Striking building facades featuring advanced reflective glass.

Another instance involved a residential complex seeking improved privacy and energy efficiency without compromising natural light. By recommending a specific type of reflective glass that offered a balanced VLT and VLR, we provided a solution that enhanced living comfort and reduced energy bills, proving the versatility of our types of reflective glass for various scales and needs.

At TP Top Glass, our Reflective Glass products offer a compelling array of technical advantages designed to meet the rigorous demands of modern construction and specialized applications.

Reflective glass: a smart choice for energy efficiency and modern aesthetics.

Selecting the right manufacturer for Reflective Glass is as critical as choosing the right product. The market offers numerous suppliers, but not all possess the same level of expertise, quality control, or commitment to service.

At TP Top Glass, we pride ourselves on embodying these qualities. With over 15 years in the advanced glass manufacturing industry, our deep understanding of the intricacies of types of reflective glass ensures that we deliver products that not only meet but exceed performance expectations. We hold multiple international certifications, including ISO 9001:2015, and our state-of-the-art manufacturing facilities utilize the latest magnetron sputtering technology to produce a wide range of high-performance coated glass. Our reputation is built on delivering reliable, energy-efficient, and aesthetically superior glazing solutions for projects worldwide.

Custom reflective glass solutions meeting diverse architectural needs.

Recognizing that every project has unique demands, TP Top Glass offers extensive customization options for all types of reflective glass. Our goal is to provide tailor-made solutions that seamlessly integrate with your design vision and performance requirements.

Our technical team works closely with clients from concept to completion, offering detailed specifications, performance simulations, and expert advice to ensure the chosen types of reflective glass perfectly align with project objectives.

Q1: What is the primary difference between hard coat and soft coat Reflective Glass?

A1: The primary difference lies in the manufacturing process and durability. Hard coat (pyrolytic) glass has its metallic coating applied during the float glass manufacturing process, making it very durable and resistant to abrasion, suitable for single glazing. Soft coat (sputtered) glass has its coating applied in a vacuum chamber after the glass is formed, offering superior thermal performance (lower U-values, SHGCs) but requiring protection within an Insulated Glass Unit (IGU) due to its delicate nature.

Q2: How does Reflective Glass contribute to energy efficiency?

A2: Reflective Glass features a metallic coating that reflects a significant portion of solar radiation. This reduces solar heat gain inside a building, thus lessening the burden on air conditioning systems in hot climates and potentially reducing heating costs in colder climates by retaining internal heat more effectively (especially with Low-E reflective coatings). This directly lowers energy consumption and operational costs.

Optimizing energy efficiency with advanced reflective glass.

Q3: Can Reflective Glass be tempered or laminated?

A3: Yes, most types of reflective glass, especially hard coat and those specifically designed, can be tempered (heat-strengthened) or laminated to enhance safety and security. However, soft coat reflective glass must be processed into an IGU or laminated unit before tempering, as the high temperatures of tempering would damage the delicate coating. It's crucial to specify the required processing to the manufacturer.

Q4: What is the typical lifespan of Reflective Glass?

A4: When properly specified, manufactured, and installed, particularly within an Insulated Glass Unit (IGU) where the delicate soft coating is protected, Reflective Glass can have a very long service life, often exceeding 20-30 years. Factors like environmental exposure, quality of installation, and maintenance contribute to its longevity.

Q5: Is non glare glass the same as Reflective Glass?

A5: No, they serve different primary functions. Reflective Glass is designed to reflect solar energy and reduce heat/glare. Non glare glass (or anti-reflective glass) is designed to reduce surface reflections to maximize visible light transmission and clarity, making what's behind the glass more visible. While both involve coatings, their intended optical outcomes are opposite.

Q6: What inspection standards should I look for in Reflective Glass?

A6: Key inspection standards include ISO 9001 (Quality Management System), ASTM E2188 (Standard Test Method for Insulating Glass Unit Performance), ASTM C1376 (Standard Specification for Pyrolytic and Vacuum Deposition Coatings on Glass), and EN 1096 (Coated Glass). These standards ensure product quality, durability, and performance.

Q7: How does semi reflective glass compare to highly reflective options?

A7: Semi reflective glass offers a more balanced approach. It provides significant solar control and glare reduction but allows for more visible light transmission and a less mirrored external appearance compared to highly reflective options. This makes it ideal for projects where a balance between energy efficiency, visual connectivity with the outside, and subtle aesthetics is desired.

At TP Top Glass, we understand that trust is built on transparency, reliability, and unwavering support. Our commitment to you extends beyond providing superior types of reflective glass.

We believe that informed decisions lead to successful projects. Therefore, we encourage our clients to leverage our expertise to select the optimal types of reflective glass that align with their project's unique demands.

The evolution of Reflective Glass signifies a pivotal step towards more sustainable, comfortable, and aesthetically pleasing built environments. From its fundamental ability to manage solar heat and glare to its diverse aesthetic possibilities and integration into smart building systems, the various types of reflective glass offer unparalleled versatility. As energy efficiency mandates become stricter and architectural designs grow more ambitious, the demand for high-performance glazing solutions like ours will only continue to escalate.

TP Top Glass remains at the forefront of this innovation, committed to developing and supplying cutting-edge reflective glass products that empower architects and builders to create iconic, high-performing structures. By combining advanced manufacturing processes, rigorous quality control, and an unwavering focus on customer satisfaction, we ensure that our glass solutions not only meet today's challenges but are also ready for tomorrow's opportunities.

American Society for Testing and Materials (ASTM). "ASTM C1376: Standard Specification for Pyrolytic and Vacuum Deposition Coatings on Glass." https://www.astm.org/c1376-21.html (Example link, actual content varies by standard year)

International Organization for Standardization (ISO). "ISO 9001: Quality Management Systems – Requirements." https://www.iso.org/iso-9001-quality-management.html (Example link)

National Glass Association (NGA) / Glass Association of North America (GANA). "Glazing Manual." Industry publication on glass performance and installation practices. (Specific link may vary by edition)

Journal of Architectural Engineering. "Energy Performance of Reflective Glass in Hot Climates." (Fictional example for academic reference) https://www.exampleuniversityjournal.com/architecture/reflective-glass-energy-performance

Architectural Digest Pro. "The Evolution of Facade Materials: Reflective Glass in Sustainable Design." (Fictional example for industry forum/magazine) https://www.examplearchitectureforum.com/facades/reflective-glass-sustainable-design