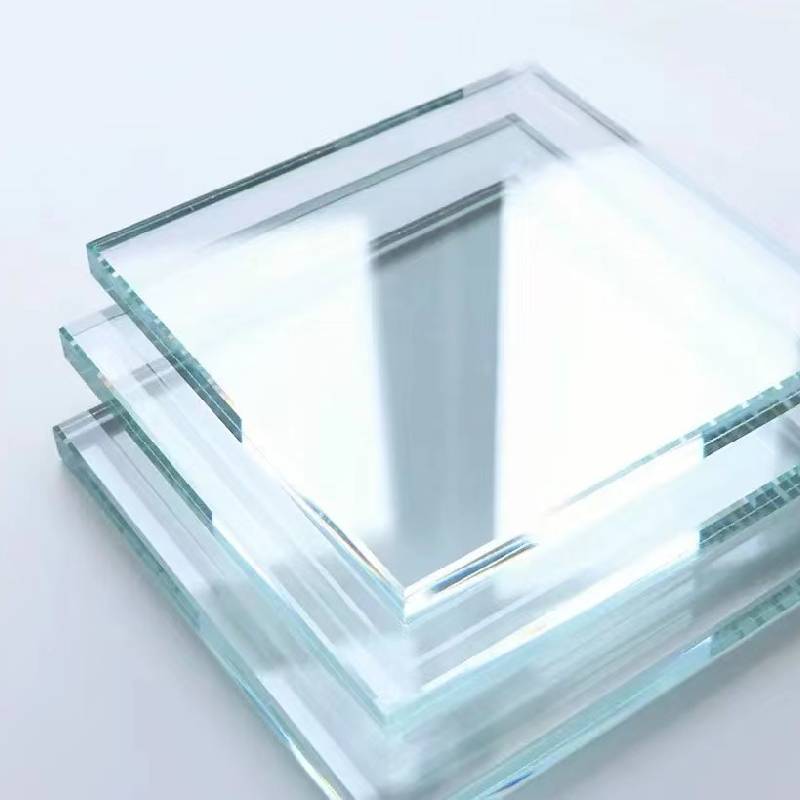

In a world increasingly driven by aesthetics, performance, and sustainability, the demand for materials that offer unparalleled clarity and efficiency has never been higher. Among these, ultra clear glass stands out as a revolutionary material, transforming architectural designs, solar energy solutions, and high-end product displays. This in-depth guide explores the multifaceted aspects of this extraordinary material, from its innovative manufacturing processes to its diverse applications, technical advantages, and the crucial factors in selecting a reliable supplier.

The global glass industry is witnessing a significant shift towards high-performance products. Traditional clear float glass, while versatile, contains a noticeable green tint, particularly visible at the edges or in thicker panels, due to its iron content. This inherent characteristic limits its application in scenarios demanding true color neutrality and maximum light transmission.

Enter ultra clear glass, also known as low iron ultra clear glass or extra clear float glass. This specialized product minimizes the ferrous oxide content present in the raw materials, resulting in a glass that boasts exceptional light transmittance and virtually eliminates the green tint. This innovation is not merely an aesthetic upgrade; it’s a functional revolution, addressing critical needs in:

The market trend indicates a sustained growth in demand for ultra clear glass, driven by stricter energy efficiency regulations, the expansion of renewable energy infrastructure, and evolving architectural preferences for minimalist and brightly lit spaces. The increasing awareness of environmental benefits, such as reduced need for artificial lighting, further fuels this demand.

The superior performance of ultra clear glass is quantifiable. Its distinguishing features lie in its optical properties, primarily driven by its ultra-low iron content. Below is a comparison of typical technical parameters between standard clear float glass and ultra clear float glass:

| Property | Ultra Clear Glass (Product: Ultra Clear Glass) | Standard Clear Glass | Unit |

|---|---|---|---|

| Iron Content (Fe2O3) | <0.01% | ~0.10% | % by weight |

| Visible Light Transmittance (3mm) | ≥91.5% | ~89% | % |

| Solar Energy Transmittance (3mm) | ≥90% | ~86% | % |

| UV Transmittance (3mm) | ~65-70% | ~55-60% | % |

| Color Rendition Index (CRI) | >99 | ~95 | Index |

| Thickness Range | 2mm - 19mm | 2mm - 19mm | mm |

| Density | 2.5 g/cm³ | 2.5 g/cm³ | g/cm³ |

| Mohs Hardness | 6-7 | 6-7 | - |

Note: Specific values may vary slightly based on manufacturing process and precise composition. Data based on typical industry standards and testing protocols.

The production of ultra clear glass, specifically low iron ultra clear glass, is a testament to advanced material science and engineering precision. The core difference from standard float glass lies in the careful selection and processing of raw materials to drastically reduce iron impurities.

[Image/Video Placeholder: Ultra Clear Glass Manufacturing Process Flow]

(A typical manufacturing process would involve a continuous flow from raw material preparation, melting, floating on a tin bath, annealing in a lehr, cutting, and finally quality inspection. Each step requires precise control to achieve the desired clarity and properties of ultra clear glass.)

The journey begins with meticulously selected raw materials. Unlike standard glass, which uses sand with a higher iron content, ultra clear glass demands high-purity silica sand, limestone, dolomite, and soda ash, all with exceptionally low iron oxide (Fe2O3) levels, typically below 0.01%. These ingredients are precisely weighed and mixed to form the "batch." This careful selection of product material is the foundation of its superior clarity.

The batch is fed into a massive furnace, where it is heated to extremely high temperatures (around 1600°C - 1700°C). This high-temperature environment facilitates the complete melting of the raw materials into a molten glass "frit." Advanced melting techniques and precise temperature control ensure homogeneity and further reduce impurities.

The molten glass then flows from the furnace onto a bath of molten tin. This is the "float" process, which is critical for achieving the perfectly flat and parallel surfaces characteristic of high-quality flat glass. The glass floats on the tin, achieving uniform thickness and a naturally fire-polished surface without any grinding or polishing.

As the glass ribbon moves along the tin bath, it gradually cools down in a controlled environment called a "lehr." This annealing process slowly reduces the temperature, removing internal stresses that could lead to cracking or shattering. This step is crucial for the glass's structural integrity and strength, ensuring a long use life.

Once cooled, the continuous glass ribbon is cut into desired sizes. Each sheet undergoes stringent quality control. This includes optical inspection for defects, measurement of thickness, and verification of light transmittance using spectrophotometers. Adherence to international inspection standards like ISO 9001 and ANSI Z97.1 is paramount here, ensuring the final product quality meets the highest benchmarks.

For applications requiring enhanced safety and strength, the ultra clear glass can undergo further processing, such as tempering. Ultra clear tempered glass is heated to approximately 700°C and then rapidly cooled, creating compressive stress on the surface. This process significantly increases the glass's resistance to impact and thermal shock, and if broken, it shatters into small, blunt pieces, reducing injury risk. Other processes include lamination, coating, or edge working depending on the specific application.

The benefits of using ultra clear glass extend beyond mere aesthetics. Its unique properties offer substantial functional and economic advantages across various applications:

Modern architectural marvels often feature extensive use of ultra clear glass to maximize natural light and achieve a sleek, transparent aesthetic. This image exemplifies its application in contemporary building designs.

Selecting the right manufacturer for ultra clear glass is crucial to ensuring product quality and project success. While many suppliers exist, distinguishing between them requires a focus on several key aspects that speak to their authoritativeness and trustworthiness:

One of the significant advantages of working with an experienced ultra clear glass manufacturer like TPTOP Glass is the ability to offer highly customized solutions. Every project has unique requirements, and standard off-the-shelf products may not always suffice. Customization options for ultra transparent glass include:

Our engineering team works closely with architects, designers, and contractors to translate complex visions into tangible, high-performance glass solutions, ensuring perfect fit and optimal functionality for every unique application. We pride ourselves on the experience gained from successfully tackling diverse custom projects worldwide.

The versatility and performance of ultra clear glass have led to its widespread adoption across numerous sectors, proving its value through practical application. Here are examples of its impactful use:

The seamless integration of ultra clear glass in interior design enhances spatial openness and light flow. This image illustrates its use in creating bright, inviting contemporary spaces. Many contemporary interior designers leverage this glass to blur the lines between indoor and outdoor environments.

While glass may not be a primary structural material in all heavy industries, ultra clear glass finds niche yet critical applications where clarity and durability are paramount, even in demanding environments. This demonstrates its robust expertise and adaptability:

At TPTOP Glass, our commitment to trustworthiness is embedded in every stage, from production to post-sales support. We understand that investing in ultra clear glass is an investment in your project's success. Our dedication to quality and customer satisfaction is a cornerstone of our operations, building on decades of accumulated experience and industry authoritativeness.

Q1: What is the primary difference between standard clear glass and ultra clear glass?

A1: The primary difference lies in the iron content. Standard clear glass contains a higher percentage of iron oxide (Fe2O3), which gives it a noticeable green tint, especially when viewed from the edge or in thicker panels. Ultra clear glass (also known as low iron ultra clear glass or extra clear float glass) has significantly reduced iron content, resulting in exceptional clarity, higher light transmittance (typically over 91.5% for 3mm thickness), and true color neutrality, making it visually superior.

Q2: How is the "low iron" property achieved in ultra clear glass manufacturing?

A2: The "low iron" property is achieved primarily through the careful selection of raw materials. High-purity silica sand and other components with minimal iron oxide impurities are used. Advanced manufacturing processes also help in reducing any trace amounts of iron during the melting and refining stages of the float glass production, ensuring minimal residual ferrous oxide.

Q3: Can ultra clear glass be tempered or laminated?

A3: Yes, absolutely. Ultra clear glass can undergo various secondary processing methods. It can be tempered to produce ultra clear tempered glass for enhanced safety and strength (shattering into small, blunt pieces upon breakage). It can also be laminated to create laminated ultra clear glass for improved security, acoustic insulation, and UV protection, all while maintaining its superior optical clarity. These processes adhere to strict industry standards like EN 12150 for tempering.

Q4: What are the main applications for ultra clear glass?

A4: Its main applications include high-end architectural facades, skylights, balustrades, and interior partitions where maximum light penetration and true color rendition are desired. It's also extensively used in solar panels (as solar glass for improved efficiency), museum display cases, high-end furniture, retail showcases, and electronic displays due to its exceptional transparency and aesthetic appeal. Its versatility makes it suitable for any application demanding visual purity.

Q5: Does ultra clear glass offer better UV protection than standard glass?

A5: Inherently, the basic composition of ultra clear glass may offer similar or slightly higher UV transmittance compared to standard float glass because the iron content (which absorbs some UV) is reduced. However, for applications requiring significant UV protection, specialized UV-blocking coatings or laminates with UV-resistant interlayers (e.g., PVB, SGP) can be applied to ultra clear glass to achieve superior UV filtration (blocking up to 99% of UV rays) without compromising its visible light clarity.

Q6: What are the typical thickness options and installation standards for ultra clear glass?

A6: Ultra clear glass is typically available in a wide range of thicknesses, commonly from 2mm up to 19mm, catering to diverse structural and aesthetic needs. Installation standards vary by region and application; however, general guidelines follow codes like ASTM, ANSI (e.g., ANSI Z97.1 for safety glazing), EN (e.g., EN 12150 for tempered glass), and local building codes (e.g., International Building Code in the US). Proper glazing techniques, sealant selection, and frame compatibility are crucial for safe and long-lasting installations.

Q7: How does ultra clear glass contribute to energy efficiency in buildings?

A7: In buildings, ultra clear glass maximizes natural daylight penetration due to its high visible light transmittance. This reduces the reliance on artificial lighting, thereby lowering electricity consumption and associated energy costs. When used in insulated glass units (IGUs) with appropriate coatings (like low-e), it can also significantly improve thermal insulation, reducing heat loss in winter and heat gain in summer. This combination leads to a more stable indoor climate and a substantial reduction in HVAC (Heating, Ventilation, and Air Conditioning) energy consumption, contributing to LEED certifications and green building initiatives.

Ready to elevate your project with the unparalleled clarity and performance of Ultra Clear Glass?

Contact TPTOP Glass for Custom Solutions!