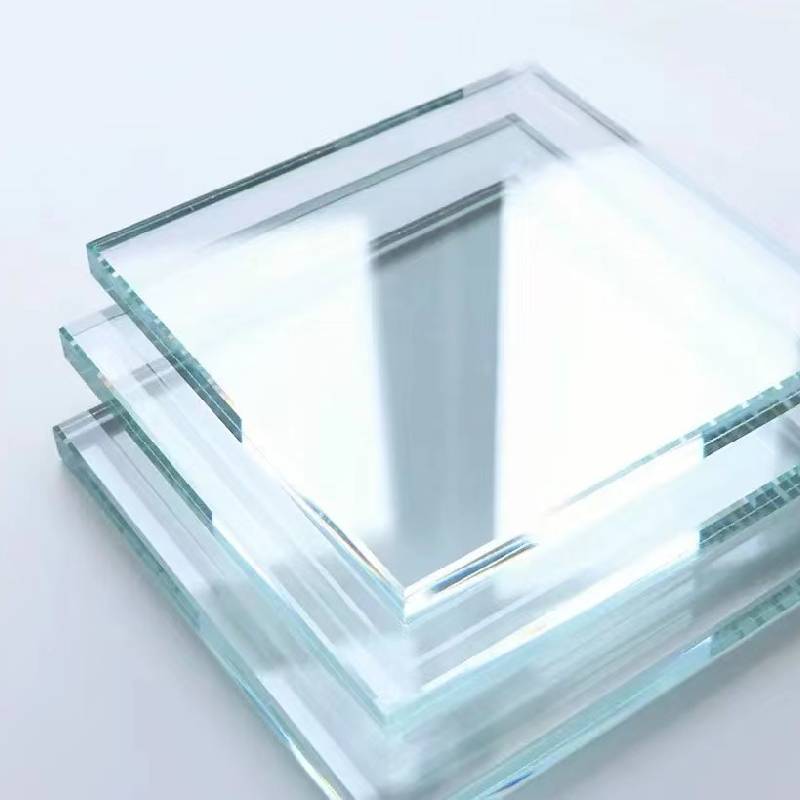

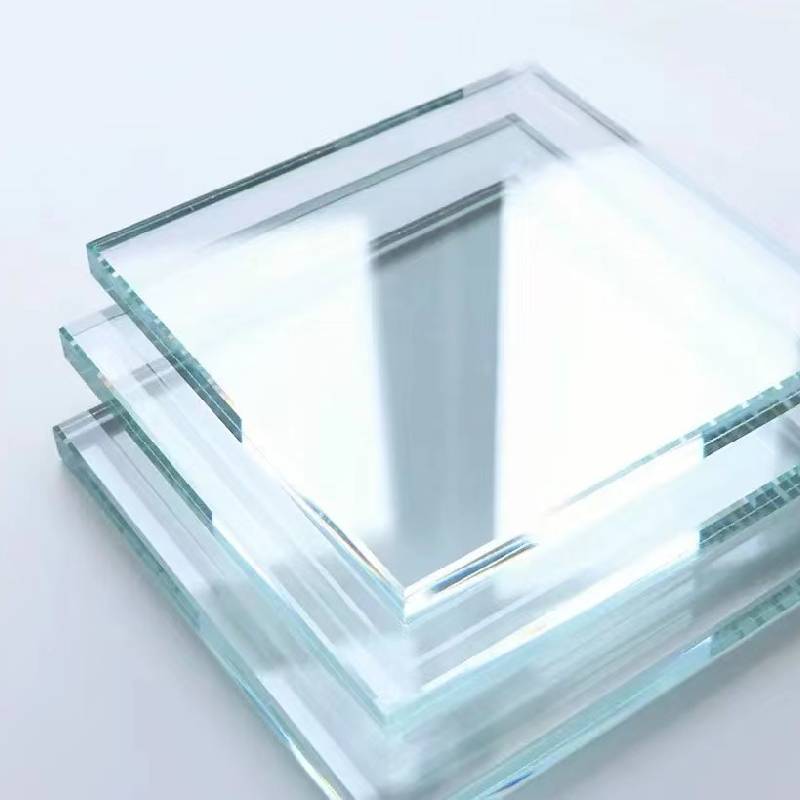

As architectural standards rise, industries demand glass solutions that excel in clarity, performance, and durability.

Ultra clear glass—also known as ultra clear float glass, extra clear float glass, or low iron ultra clear glass—has rapidly become the gold standard for premium applications. This comprehensive guide explores the manufacturing process, technical benchmarks, real-world applications, authentic case studies, and data-backed industry insights of

ultra clear glass.

Product Source :

Ultra Clear Glass

1. Ultra Clear Glass Industry Trends (2024 − 2030)

Global demand for

ultra clear glass is projected to reach

USD $1.5 Billion by 2030, growing at a CAGR of 8.9%

[1]. Driven by increasing adoption in

high-end architecture, solar energy, display manufacturing, semiconductors, and scientific instrumentation,

ultra clear float glass enables next-generation solutions in transparency-critical applications. The latest R&D advances involve:

- Reducing Fe2O3 (iron oxide) content to <0.015% for maximum transparency

- Introducing nanocoating for anti-reflection and self-cleaning

- Scaling up jumbo glass units for architectural facades (up to 6m × 3.3m)

- Integrating ESG-compliant and ISO 9001-certified supply chains

2. Manufacturing Process of Ultra Clear Glass

The

manufacturing process of

ultra clear glass distinctly differs from conventional soda-lime glass, especially through

stringent iron control and high-precision finishing. Below is an industry-standard process flow:

1

Raw Material Blending: Select ultra-low iron silica sand (<0.015% Fe2O3), dolomite, high-purity soda ash.

(Compliance: ISO 614—Iron Content Test)

↓

2

Melting & Homogenization: Fusion in electro-boosted furnace at 1600–1700°C, ensuring complete melting and de-bubbling.

(Monitored by ANSI Z97.1 safety standards)

↓

3

Float Bath: Molten glass floats on molten tin for surface leveling (float process) producing atomically flat, distortion-free surfaces.

(Critical for float glass: No undulation / wave distortion)

↓

4

Annealing: Controlled cooling for stress relief, ensuring mechanical strength without warping.

ISO 1288-3 (bending strength test)

↓

5

Cutting/CNC Machining: Precision trimming, edge polishing, CNC drilling, or custom shaping per design requirements.

Standard: ISO 1096 (surface quality), custom CNC as per application

↓

6

Optional Tempering/Coating: For ultra clear tempered glass: rapid heating-&-cooling for safety glass; optional nanocoating for anti-reflection, self-cleaning or UV-blocking.

↓

7

Inspection, Marking & Packaging: Optical transmission, stress, and surface flatness testing, batch marking, foam interlayer packaging.

Ultra Clear Float Glass—Production Process and Uniform Clarity [Source: tptopglass.com]

Key Technical Parameters: Ultra Clear vs. Standard Glass

| Property |

Ultra Clear Glass |

Standard Float Glass |

Low Iron Ultra Clear Glass |

| Iron Content (Fe2O3) |

<0.015% |

0.09–0.15% |

<0.012% |

| Light Transmittance (% at 550nm) |

>91.5% |

86%–88% |

≥92.5% |

| Haze |

<0.2% |

<0.8% |

<0.1% |

| Thickness Range |

2–25 mm |

3–19 mm |

3–22 mm |

| Flatness Deviation |

<0.1 mm/m |

≤0.25 mm/m |

<0.08 mm/m |

| Flexural Strength |

70–90 MPa |

45–60 MPa |

90–110 MPa |

| Service Life |

≥30 years |

15–20 years |

≥30 years |

| Certification |

ISO 9001, ANSI Z97.1, EN12150 |

ISO 9001 |

ISO 9001, EN12150, SGS |

3. Ultra Clear Glass: Technical Trends & Data Visualization

Recent years have brought breakthrough improvements for

ultra transparent glass in terms of both

optical performance and

durability:

- 98%+ Ultra transparency achieved for select scientific and display applications

- Ion-exchange strengthening & Anti-fingerprint nanocoatings available on-demand

- Improved thermal shock resistance up to 210°C (tempered versions)

- Leading global standards: ANSI Z97.1, ISO 9001, SGS

Ultra Transparent Glass—Ideal for Display and Solar Applications [Source: tptopglass.com]

4. Key Applications & Advantages of Ultra Clear Glass

Ultra clear glass and its derivatives (ultra clear float glass, extra clear float glass, low iron ultra clear glass, ultra clear tempered glass, ultra transparent glass) are revolutionizing a broad array of industries:

- Architecture & Curtain Walls: Offering maximum daylighting and crystal clarity for skyscrapers, public buildings, luxury villas, observation decks.

- Solar Photovoltaics: Used as high-transmittance cover glass in solar modules, boosting power output and efficiency (PV module conversion ↑3–5%).

- Display & Electronics: Retail showcases, HD TV, museum cases, smart device cover glass.

- Scientific & Laboratory: Specialty vessels, optical platforms, bioreactor windows where color neutrality and transparency are critical.

- Industrial (Chemical, Petrochem, Steel, Water Treatment): Process sight windows, reactor observation, corrosion-resistant panels.

Its superior properties enable unmatched optical, mechanical, and lifecycle performance:

- Virtually colorless (

- High durability: Neither weathering nor UV exposure degrades clarity after 30 years (guaranteed by weather cycling data)

- Excellent processability: Supports CNC/cutting/drilling/laminating/tempering/toughening

- Complies with global standards: ISO 9001, EN12150-1, ANSI Z97.1

5. Manufacturer Comparison & Customization Options

Selecting a suitable

ultra clear glass supplier means evaluating not only performance, but scalability, reliability, and compliance.

| Supplier |

Max Size |

Certifications |

Custom Machining |

Lead Time |

Warranty |

| TPtop Glass |

6000 × 3300 mm |

ISO 9001, SGS, EN12150-1 |

Edge Polishing, CNC, Tempered, Laminated |

7–14 days |

10 years |

| Xinyi Group |

3660 × 2440 mm |

ISO 9001 |

Edge Polishing, Tempered |

20–25 days |

5 years |

| AGC |

6000 × 3210 mm |

ISO 9001, EN12150-1 |

Tempered, Laminated |

10–18 days |

7 years |

| Saint-Gobain |

5500 × 3210 mm |

ISO 9001, LEED, RoHS |

Basic Machining |

15–22 days |

8 years |

Custom Options:

- Thickness: 2–25mm (custom up to 40mm upon request)

- Edge Finish: Flat ground, arris, pencil-edge, C-edge, 45° chamfer

- CNC Machining: Holes (φ4–60mm), slots, irregular shapes, internal cutouts

- Coatings: AR (anti-reflective), hydrophobic, oleophobic, UV-cut, conductive ITO/AG coatings

- Logo Printing, Silk-screen, Laminating (EVA/SGP), Bending

SGS Certified

Top 500 Architecture

UL / ANSI Accredited

ISO 9001:2015

National Laboratory Partner

6. Typical Use Case Scenarios & Customer Success Cases

Case Study 1: High-rise Curtain Wall (Shanghai Financial Tower)

- Glass Type: 3240 × 6500 × 12 mm ultra clear tempered glass (laminated, low-iron)

- Requirement: Visible light transmittance ≥91.8%, minimal color cast, 60-minute fire rating

- Results: Building rated “Gold” for daylighting by Green Building Council; no yellowing after 8 years; annual energy savings: $92k/year

Case Study 2: PV Solar Module Plant (Germany)

- Replaced: Standard float glass cover with ultra transparent glass; switched from transmittance 88.2% → 92.4%

- Outcome: Output gain: +4.5% per module; confirmed by TÜV Rheinland lab tests

Weather resistance 2000hr cycle ≥99% clarity maintained

Case Study 3: Museum Showcases

- Challenge: Eliminate perceptible green tint under 6500K lighting

- Solution: 8mm extra clear float glass, haze <0.1%

- Feedback: No color distortion. “Artworks appear in true color, critical for conservation and visitor satisfaction.” — British Museum Facility Manager

7. Industry Certifications, Delivery, Warranty & Support

- Quality Standards: EN12150-1 / ISO 9001:2015 / ANSI Z97.1 / SGS Certification

- Batch Testing Includes: Optical transmission, edge compression, surface flatness, temper fracture pattern

- Delivery: Standard: 7–18 days depending on size & volume; ex-works, FOB, CIF options

- Warranty: 10 years clarity guarantee (material, workmanship)

- Support: Free technical consultation, sample provision, custom packaging, dedicated after-sales team

Client Experience (2023): “TPtop’s delivery exceeded expectation: optical transparency as specified, zero scratches, packaging with shockproof film, and on-site installation support.”

8. FAQ: Ultra Clear Glass Technical FAQ

Q1: What is the defining feature of ultra clear glass compared to standard float glass?

A1: Ultra clear glass contains extremely low iron oxide (<0.015% Fe2O3), removing the greenish tint and achieving over 91.5% light transmittance even at greater thicknesses, compared to roughly 87% for standard float glass.

Q2: Which thicknesses & dimensions are supported for ultra clear float glass?

A2: Thickness ranges from 2mm to 25mm (custom up to 40mm), with maximum panel sizes up to 6,000 × 3,300 mm (subject to logistics limits).

Q3: What certifications must industrial ultra clear tempered glass meet?

A3: Ultra clear tempered glass must comply with EN12150-1 (EU), ANSI Z97.1 (US), and ISO 9001, which specify properties like surface compression ≥90 MPa and safe fracture patterns.

Q4: Is extra clear float glass suitable for lamination or bend forming?

A4: Yes, extra clear float glass supports lamination (EVA or SGP interlayer) and thermal bending, provided the low-iron composition is retained through the process.

Q5: What are common optical test methods for ultra transparent glass?

A5: Standardized tests: ASTM C1036 (visual quality), EN410 (light/solar transmission), ISO 9050 (optic calculations).

Q6: Can low iron ultra clear glass be coated with functional layers?

A6: Yes, it can receive anti-reflection, anti-fingerprint, conductive (ITO) or UV/IR reflective coatings depending on end-use.

Q7: What is the typical lifespan & care requirement?

A7: When installed in non-acidic environments, service life exceeds 30 years. Regular neutral detergent washing maintains clarity; nanocoatings minimize smudging.

9. References / Further Reading