The Reflective Glass Factory A Glimpse into Innovation and Craftsmanship

In the heart of an industrious landscape lies a reflective glass factory, a realm where innovation meets craftsmanship, and where ordinary materials are transformed into extraordinary products. Reflective glass, known for its unique ability to reflect light while allowing for visibility, plays a crucial role in architecture, automotive design, and interior decoration. This article takes you through the journey of a reflective glass factory, exploring its processes, products, and the impact it has on our environment and society.

The Art of Glassmaking

The art of glassmaking is an ancient craft that has evolved dramatically over the years. At the reflective glass factory, the process begins with the selection of raw materials—primarily silica sand, soda ash, and limestone. These ingredients are meticulously measured and mixed to create a homogeneous batch known as glass feed. This mixture is then heated to extreme temperatures in a furnace that can reach upwards of 1,700 degrees Celsius. As the materials melt, they transform into a viscous liquid, ready to be shaped into various forms.

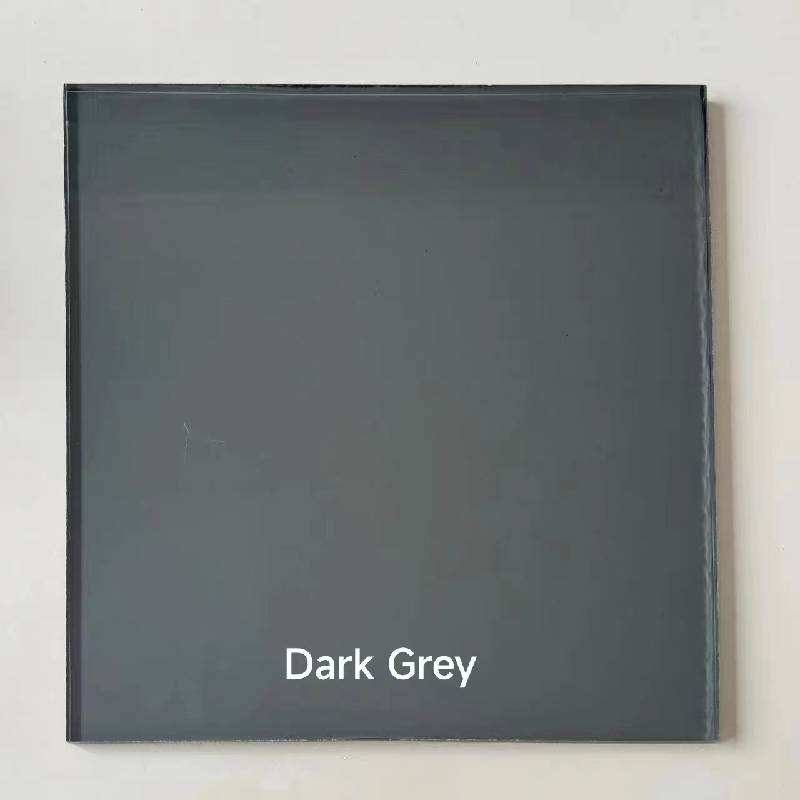

Once the glass is molten, it is poured into molds or formed using advanced machinery to create sheets of reflective glass. The reflective quality is achieved through the application of a metal coating, typically aluminum or silver, which is deposited onto one side of the glass in a vacuum chamber. This thin layer reflects light and enhances the aesthetic appeal of the glass, offering a sleek, modern finish that is highly sought after in contemporary design.

Quality Control and Precision

Quality control is paramount in the production of reflective glass. After the initial formation, each sheet undergoes rigorous testing to ensure it meets industry standards for clarity, durability, and reflection. Technicians inspect every inch of the glass for imperfections, such as bubbles or scratches. Any defective pieces are discarded or recycled, emphasizing the factory's commitment to quality and sustainability.

Moreover, the factory utilizes state-of-the-art technology to streamline the manufacturing process. Computerized cutting machines and automated handling systems improve efficiency and accuracy, allowing for faster production times without compromising quality. This technological integration not only enhances productivity but also reduces waste, making the factory an environmentally conscious operation.

An Eco-Friendly Approach

As environmental concerns grow, the reflective glass factory has embraced sustainable practices. The factory has implemented processes to minimize its carbon footprint, such as using recycled glass in the manufacturing process. In fact, recycled glass can be re-melted and reformed with minimal energy consumption, thus conserving natural resources and reducing landfill waste.

Additionally, the reflective properties of the glass contribute to energy efficiency in buildings. Reflective glass reduces heat gain from sunlight, helping to maintain comfortable interior temperatures while lowering the energy consumption of air conditioning systems. This innovative product is not just a testament to technological advancement; it also represents a commitment to creating greener, more sustainable architectural solutions.

Applications and Impact

Reflective glass is versatile, and its applications span across various sectors. In architecture, it enhances the aesthetic appeal of skyscrapers, office buildings, and homes. It provides privacy without sacrificing natural light, making it a popular choice for modern construction. In the automotive industry, reflective glass improves safety and comfort by reducing glare for drivers while providing a sleek exterior finish for vehicles.

The impact of reflective glass extends to interior design, where it is used in mirrors, furniture, and decorative elements. The ability to create illusions of space and light makes reflective glass a favorite among interior designers looking to elevate their projects.

Conclusion

The reflective glass factory stands as a beacon of innovation and craftsmanship in the modern industrial landscape. Through advanced technology, stringent quality control, and eco-friendly practices, it not only produces high-quality glass products but also contributes to a sustainable future. As the demand for reflective glass continues to rise, this factory exemplifies how the fusion of tradition and innovation can lead to remarkable advancements in design and environmental stewardship. The reflective glass factory is not just a place of business; it is a testament to the potential of human creativity and responsibility in shaping our world.