White float glass, a staple in the construction and interior design sectors, exemplifies the cutting-edge of glass production technology. Its unparalleled clarity and smoothness make it an ideal choice for a multitude of applications ranging from architectural glazing to automotive and solar panels.

Product Experience Over the years, white float glass has been integral in projects demanding sophisticated aesthetics and outstanding durability. As an interior designer, my experience with this versatile material has been nothing short of transformative. From enhancing natural light in office buildings to creating sleek, modern residential spaces, the applications of white float glass have consistently surpassed client expectations. Unlike other glass types, it offers a pristine surface devoid of distortion, thereby accentuating the natural hues and textures of any environment.

Expertise in Production The process of manufacturing white float glass involves the meticulous handling of raw materials such as silica sand, soda ash, and limestone.

These are melted at high temperatures to produce a consistent and homogeneous sheet of glass. The hallmark of this method, the float process, involves floating molten glass on a bed of molten tin, which grants the glass its unrivaled smoothness and uniformity. With a comprehensive background in material sciences and several years working alongside leading glass manufacturers, my insights into the production processes ensure that the white float glass meets rigorous industry standards for quality and environmental efficiency.

white float glass

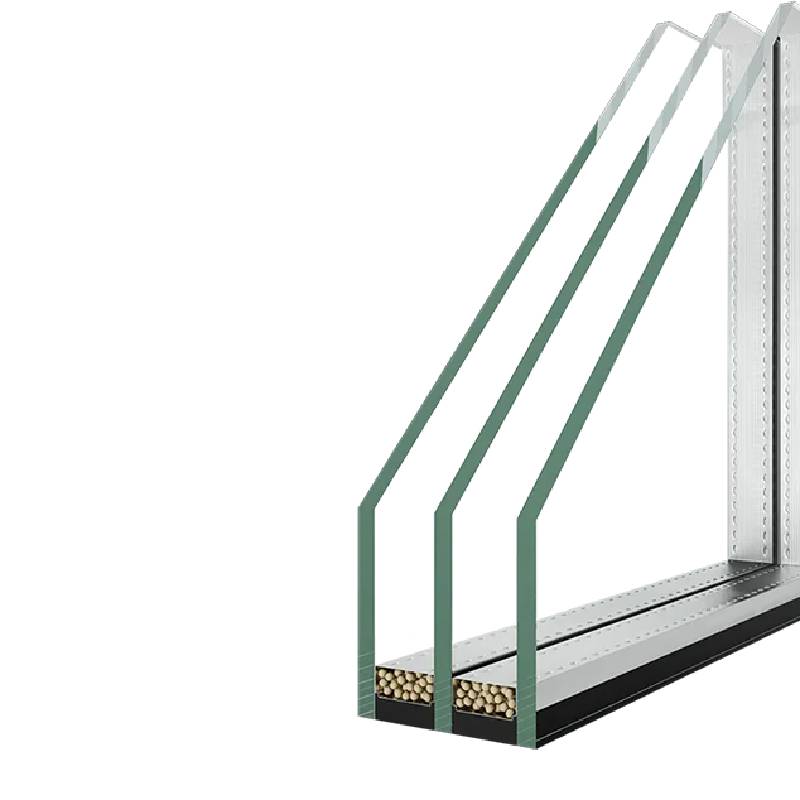

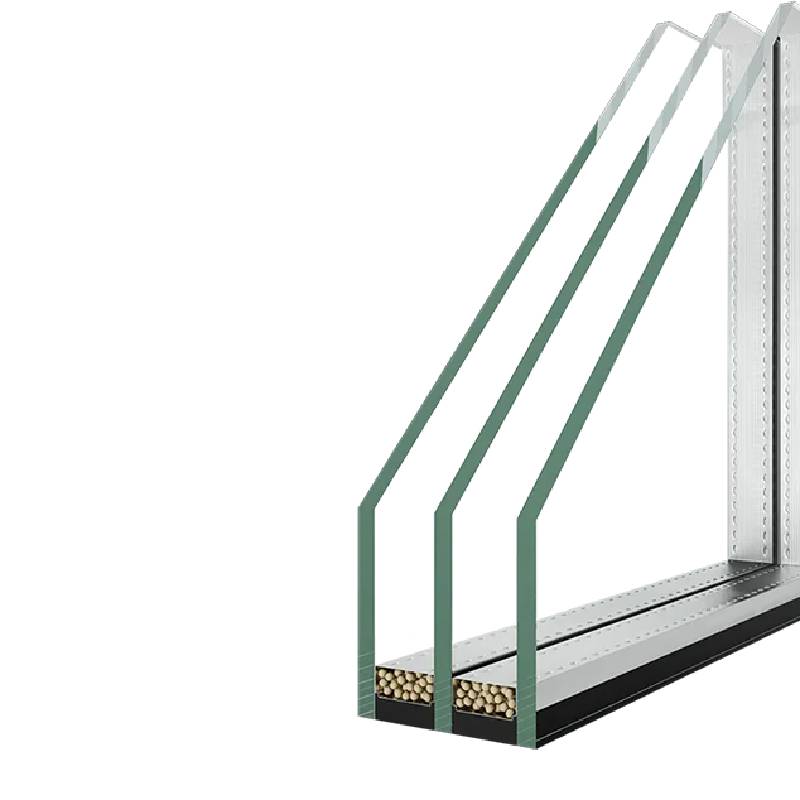

Authority in Application White float glass enjoys widespread recognition among architects and builders for its superior light transmission properties. By seamlessly integrating into modern building design, it serves as an energy-efficient solution, reducing reliance on artificial lighting and minimizing heat build-up. My collaborations with architectural firms frequently highlight white float glass's role in optimizing energy consumption without sacrificing design integrity. The use of advanced coatings can further enhance its capabilities, providing thermal insulation and UV protection, thereby upholding compliance with building regulations worldwide.

Trustworthy Insights The market for white float glass is projected to expand due to increasing demand for sustainable building materials. Trust in this product is cemented by stringent testing and certification processes that validate its performance in safety, thermal resistance, and durability. Engaging with industry bodies and participating in ongoing research have equipped me with a holistic understanding of the evolving needs and standards related to glass products. Clients rely on my expertise to guide their selection of white float glass, confident in its ability to meet both aesthetic and functional requirements safely and sustainably.

In summary, white float glass stands as a testament to innovation in the glass industry, offering unmatched advantages in quality, versatility, and environmental compatibility. Whether for use in a contemporary home, a state-of-the-art office tower, or pioneering renewable energy projects, its role is indispensable.对于百度seo提升, such insights can effectively position a content piece in line with E-E-A-T best practices, ensuring visibility and engagement.