Dead flat float glass, a marvel of modern manufacturing, is a product of choice across numerous industries due to its unparalleled smoothness, clarity, and versatility. This type of glass is produced through a meticulous process that ensures a perfectly uniform surface, making it ideal for a variety of applications. Whether used in architectural projects, automotive sectors, or interior design, dead flat float glass not only offers exceptional aesthetics but also performance and reliability.

One of the defining characteristics of dead flat float glass is its impeccable surface quality, achieved through the float glass process. During this process, molten glass is poured onto a bed of molten tin, allowing it to spread evenly. The natural forces of gravity and surface tension create a glass sheet that is almost perfectly flat and possesses a mirror-like finish. This level of flatness is crucial for industries that demand precision and clarity, such as in the production of high-definition screens and optical devices.

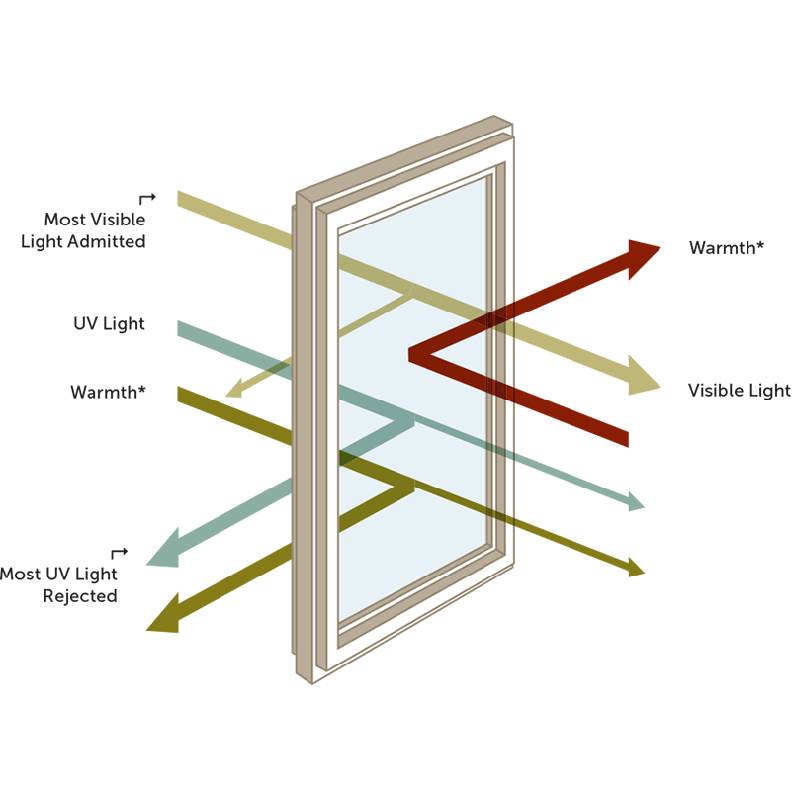

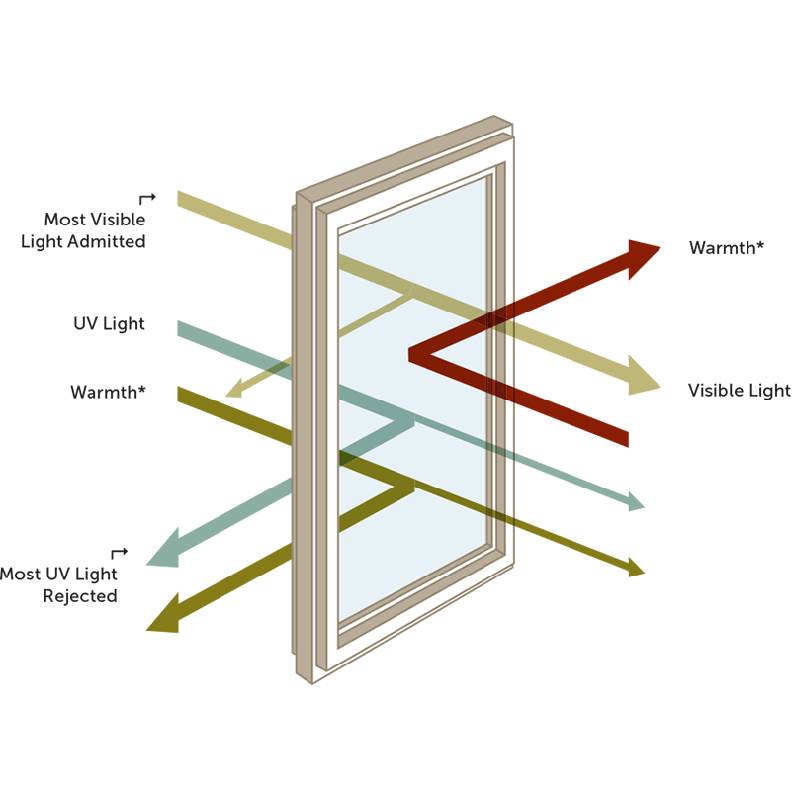

In the architectural world, dead flat float glass is often the material of choice for modern buildings seeking a sleek, contemporary style. Its ability to maximize natural light while offering unobstructed views makes it an excellent option for windows, facades, and curtain walls. The uniformity of the glass not only enhances aesthetic appeal but also contributes to energy efficiency by supporting modern glazing technologies that control the solar heat gain and provide superior insulation.

Beyond aesthetics, dead flat float glass is lauded for its structural integrity and durability. This makes it a go-to material for safety and security applications, including tempered or laminated glass, which withstands impact and provides shatter resistance. It also supports sophisticated treatments like coatings that can improve thermal performance or add decorative effects without compromising transparency.

dead flat float glass

The automotive industry benefits from dead flat float glass in a multitude of ways. High-quality glass is essential for windshields, side, and rear windows to assure clear visibility and protect passengers. The precision flatness of the float glass ensures that there are no distortions, thus providing drivers with an accurate perspective of their surroundings. When combined with advanced interlayers, it also enhances acoustic insulation, contributing to a quieter and more comfortable ride.

In interior design, dead flat float glass offers a versatile medium for creating elegant and functional spaces. Its adaptability allows it to be used in tabletops, shelving, and mirrors, where clarity and smooth edges are paramount. Additionally, its surface can be treated with various finishes for privacy, such as frosting or sandblasting, adding texture and interest without sacrificing light transmission.

From a sustainability perspective, dead flat float glass also aligns with eco-friendly practices. The manufacturing process has evolved to reduce emissions and energy consumption, reflecting the industry's commitment to environmental responsibility. Furthermore, glass is a fully recyclable material, supporting circular economy objectives and reducing the ecological footprint.

Ultimately, dead flat float glass remains an indispensable material due to its combination of aesthetic appeal, functionality, and environmental responsibility. Its use across various domains exemplifies how a seemingly simple material can enhance everyday life while embracing cutting-edge technology and design innovation. For any project demanding precision, elegance, and strength, dead flat float glass stands out as a superior choice, trusted by architects, engineers, and designers around the globe.