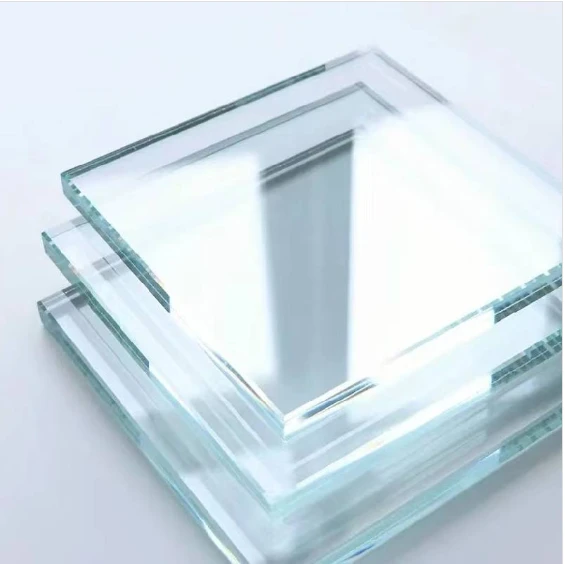

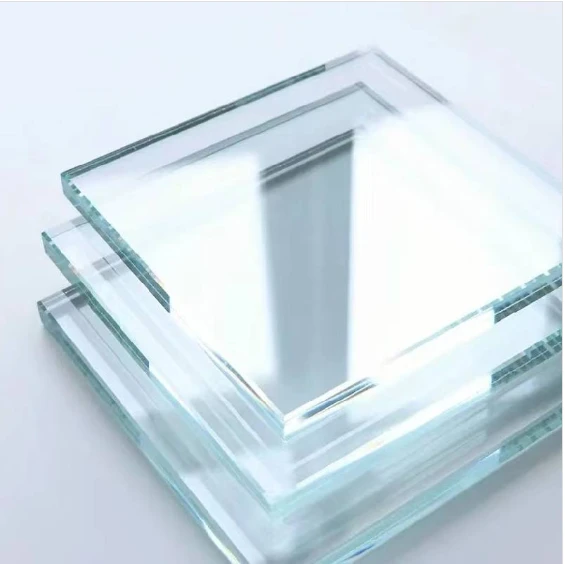

Float glass, a staple in modern architecture and construction, represents a revolutionary advancement in how we interact with light and aesthetics. Esteemed for its flawless finish and uniform thickness, float glass sets itself apart as a versatile product, favored by architects and interior designers worldwide.

The production of float glass is a marvel of precision and engineering. Known for its continuous flow process, pioneered by Sir Alastair Pilkington in the 1950s, float glass is created by floating molten glass on a bed of molten tin. This process ensures a perfectly flat surface, free from distortions and impurities, which traditional methods could not achieve. The resultant product is a glass sheet of remarkable clarity and smoothness, capable of being produced in large dimensions without sacrificing quality.

Float glass's applications are extensive. Its most prominent role is in creating transparent building facades that merge design with function, allowing natural light to penetrate deep into buildings. This not only enhances aesthetic appeal but also promotes energy efficiency, a critical consideration in today's environmentally conscious architectural practices. Moreover, its adaptability means it can be treated to produce safety glass, such as tempered or laminated glass, providing additional protection while maintaining its aesthetic advantages.

Enhancing its technical appeal, float glass can be further processed to improve its thermal insulation properties. By applying low-emissivity (Low-E) coatings, it significantly reduces heat loss in winter and minimizes heat gain in summer, contributing to reduced energy consumption and lower environmental impact. This makes float glass a cornerstone in sustainable building practices, offering a product that champions both form and function.

float glass

From an interior design perspective, the versatility of float glass is unmatched. It is used extensively in furniture, partitions, and decorative elements, offering an elegant and modern aesthetic. Architects and designers appreciate the ability to customize float glass through various techniques such as sandblasting, acid etching, or digital printing, allowing for personalized designs that fit any creative vision.

The trustworthiness of float glass lies in its proven track record. It is subjected to rigorous quality control, ensuring that each sheet meets specific standards for thickness uniformity and optical clarity. Certifications from safety and quality assurance bodies further enhance its credibility, ensuring that users receive a product of the highest caliber.

When considering float glass for a project, understanding its professional applications can provide a competitive edge. Expertise in choosing the right type of float glass, understanding its processing capabilities, and applying it effectively in construction or design projects elevates the final result, achieving both aesthetic beauty and functional excellence.

In essence, float glass not only transforms spaces through its optical properties but also aligns seamlessly with modern construction and design philosophies. Its adaptability, combined with proven reliability, positions it as a product of choice for cutting-edge projects that require both performance and style. Whether opting for transparency that invites the outside world in or using its transformative attributes to enhance energy efficiency, float glass delivers on all fronts, truly embodying the spirit of innovation and excellence.