The Promise of Pyrolytic Low-E Glass A Window to Energy Efficiency

In the pursuit of sustainable architecture and energy-efficient buildings, innovative materials play a crucial role. One such material that has gained significant attention is pyrolytic low-emissivity (Low-E) glass. This advanced glazing technology not only enhances the aesthetic appeal of structures but also contributes to significant energy savings. This article explores the properties, applications, and benefits of pyrolytic low-E glass, shedding light on its importance in modern construction.

What is Pyrolytic Low-E Glass?

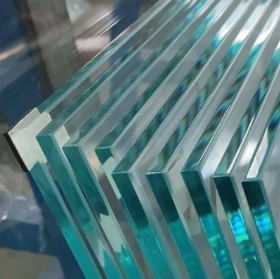

Pyrolytic low-E glass is a type of energy-efficient glazing that is coated with a microscopically thin layer of metallic oxide. This coating is applied through a pyrolytic process, where the glass is heated to high temperatures, allowing the coating to bond permanently to the glass surface. Unlike other types of low-E coatings, which may be applied afterward (i.e., sputtered coatings), pyrolytic coatings are baked into the glass during manufacturing. This process results in a durable and robust product that can withstand environmental stress and is ideal for a variety of applications.

How Does it Work?

The primary function of low-E glass is to reduce the amount of ultraviolet (UV) and infrared (IR) light that passes through the glass while allowing visible light to enter. The metallic coating reflects heat while permitting daylight illumination, effectively minimizing heat loss in winter and reducing heat gain in summer. This dynamic thermal control plays a pivotal role in improving indoor comfort and reducing the reliance on heating and cooling systems.

Benefits of Pyrolytic Low-E Glass

1. Energy Efficiency Pyrolytic low-E glass can significantly improve the energy performance of buildings. By minimizing thermal transmission, it helps maintain a consistent indoor temperature, leading to lower energy bills and reduced carbon emissions. Furthermore, buildings equipped with this glass often require smaller HVAC systems, resulting in space-saving and cost-effective designs.

2. UV Protection One of the prime benefits of low-E glass is its ability to filter out harmful UV rays. These rays can cause fading to furniture, fabrics, and artwork. By using pyrolytic low-E glass, building owners can extend the lifespan of interior finishes and reduce the need for frequent replacements.

3. Durability and Longevity The pyrolytic process ensures that the Low-E coating is robust and resilient. Unlike sputtered coatings that can wear off or get damaged during installation, the pyrolytic coating is integral to the glass surface, making it less susceptible to scratches and other forms of degradation.

4. Aesthetic Versatility Pyrolytic low-E glass is available in various tints and finishes, offering architects and designers flexibility in creating visually appealing structures. The ability to control light transmission and glare while maintaining transparency makes it suitable for various architectural styles.

5. Compliance with Building Codes Many regions have adopted energy codes that require the use of low-E glass in new constructions and renovations. Pyrolytic low-E glass meets these standards while offering additional benefits, positioning it as a smart choice for developers and builders.

Applications of Pyrolytic Low-E Glass

The applications of pyrolytic low-E glass are extensive. It is commonly used in residential and commercial buildings, storefronts, curtain walls, and even in the automotive industry for windshields. Its versatility makes it suitable for projects aiming for LEED certification and other green building initiatives. Furthermore, advancements in technology are continually improving the performance of low-E glass, leading to even more innovative uses.

Conclusion

As the need for sustainable building practices intensifies, materials like pyrolytic low-E glass stand at the forefront of the green construction movement. Offering energy efficiency, UV protection, and aesthetic flexibility, this glazing technology not only contributes to environmentally responsible design but also ensures the longevity and comfort of indoor spaces. As architects and builders seek solutions to minimize their ecological footprint, pyrolytic low-E glass proves to be an invaluable asset, enriching the built environment while safeguarding our planet. In the journey towards sustainable architecture, pyrolytic low-E glass is undeniably a shining example of innovation and progress.