White float glass, a versatile and essential product in various industries, plays a pivotal role in modern architecture, automotive sectors, and interior design due to its innate qualities and adaptability. As a cornerstone material, it combines transparency, durability, and aesthetic appeal, thus offering an unparalleled experience for both manufacturers and consumers.

Experience with white float glass is best demonstrated through its extensive application in architecture. Architects and designers favor this type of glass for its ability to allow natural light to penetrate buildings while offering insulation and soundproofing properties. This results in structures that are not only energy-efficient but also offer a serene interior environment, crucial in urban settings where such attributes significantly enhance the quality of life. Real-life projects around the globe stand as testaments to white float glass's performance, providing insights into its profound impact on building aesthetics and functionality.

Expertise in white float glass production reflects its sophisticated manufacturing process. The production begins by blending raw materials such as silica sand, soda ash, and limestone, which are then melted at high temperatures.

The molten glass floats over a bed of molten tin, forming a uniform thickness with a perfectly smooth surface on both sides. This meticulous process, honed over decades, ensures the production of high-quality glass with exceptional clarity and strength. Knowledgeable professionals in this field understand the nuances of temperature control, material composition, and machinery calibration, all of which are integral to producing superior white float glass.

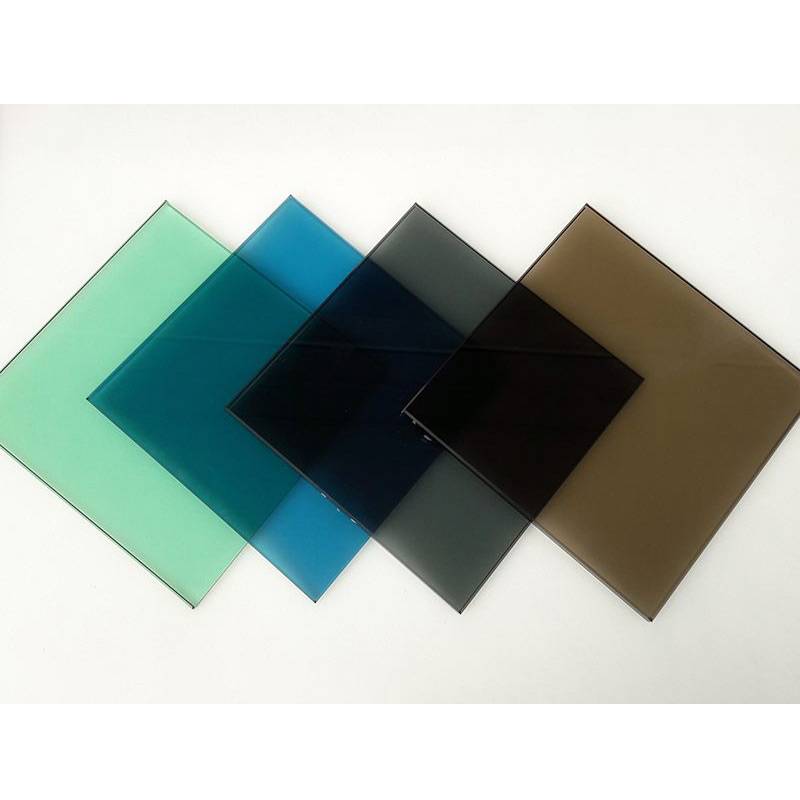

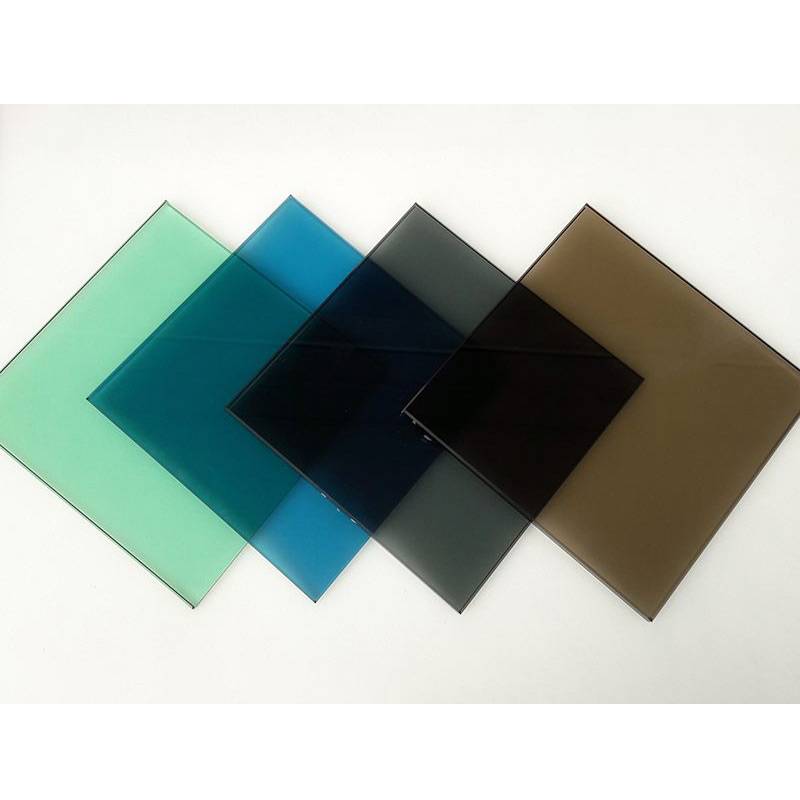

white float glass

In terms of authoritativeness, leading companies in the glass manufacturing industry continuously invest in research and development to innovate white float glass production. These authoritative firms set benchmarks for quality and safety standards, ensuring that the glass produced meets rigorous international norms. They publish substantial data and findings in peer-reviewed journals, contributing to the pool of knowledge shared among industry professionals. This established credibility not only aids in enhancing product quality but also fosters consumer trust globally.

Trustworthiness is intrinsic to white float glass manufacturers who prioritize environmental sustainability and safety. The industry's commitment to reducing the carbon footprint involves implementing recycling measures and reducing energy consumption during production. Certified by environmental agencies and organizations, their adherence to sustainable practices reassures consumers of their purchased product's environmental accountability. Moreover, robust testing processes ensure that each pane of glass meets both safety standards and consumer expectations, further solidifying trust between manufacturers and end-users.

In conclusion, white float glass is more than just a building material; it is a testament to engineering excellence and innovative spirit in the manufacturing industry. Its widespread application across various sectors underscores its importance and adaptability. With industry-leading professionals and companies continuously pushing boundaries in quality and sustainability, white float glass stands as a reliable, cutting-edge solution for modern-day demands. Whether you are an architect, developer, or engineer, investing in high-quality white float glass promises not only superior performance but also a commitment to innovation and resilience in your projects.