Float flat glass, widely recognized for its impeccable surface finish and unparalleled clarity, has become an indispensable component in various industries ranging from architecture to automotive design. Delving into the realm of float flat glass uncovers a world where innovation, precision, and durability converge, forming the backbone of modern-day engineering and design applications.

A key characteristic that sets float flat glass apart is its creation process, a marvel in itself. Developed by the visionary Alastair Pilkington in the 1950s, this process entails floating molten glass on a bed of molten tin.

This technique results in uniformly flat glass sheets with pristine surfaces free from distortions. The float process is emblematic of precision engineering and has significantly enhanced the quality and availability of flat glass in the global market.

Architectural experts often extol the virtues of float flat glass for its versatility and structural position. Used in skyscrapers and iconic edifices around the globe, the glass not only satisfies aesthetic cravings with its sleek, minimalistic appeal but also meets rigorous safety standards. Laminated or tempered variants provide robustness that withstands extreme weather conditions and potential impacts, underscoring the material's reliability.

In the automotive sector, float flat glass plays a pivotal role in balancing aesthetics with functionality. From windshields to windows, its application ensures visibility and protection, simultaneously reducing glare and enhancing energy efficiency through intelligent coatings. For automotive designers, the glass serves as a canvas through which they express sophistication without compromising on safety and durability.

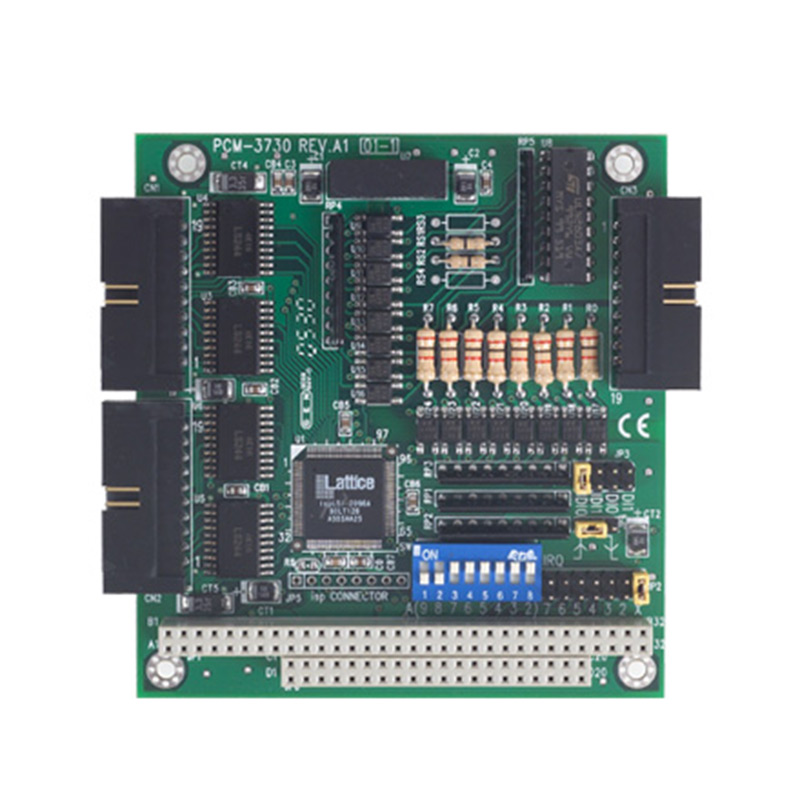

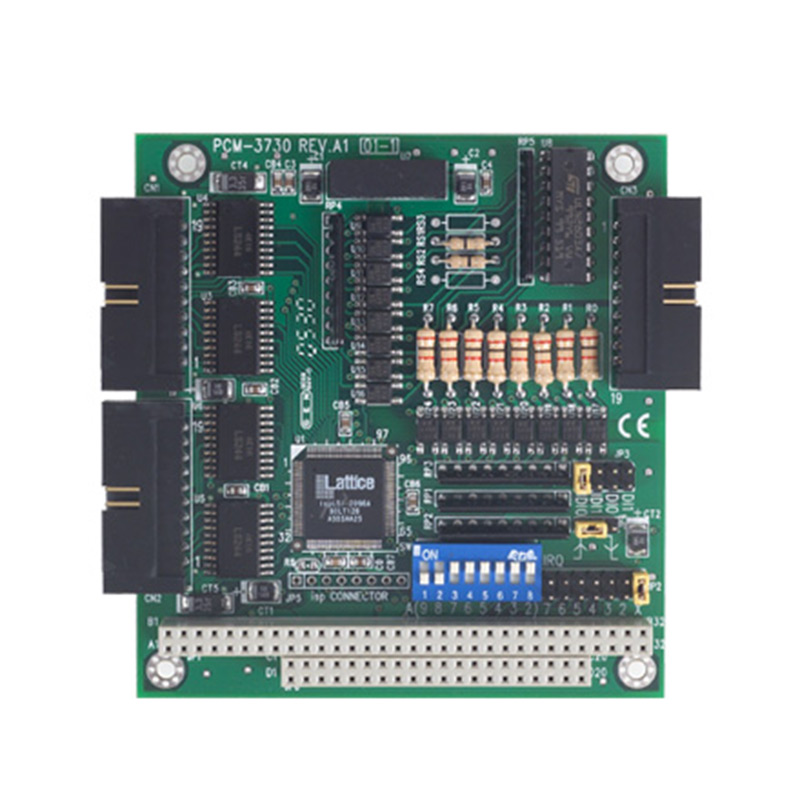

float flat glass

The innovation-driven market has led leading glass manufacturers to explore and develop specialized versions of float flat glass, tailored for specific needs. Innovations include energy-efficient low-emissivity glass, which significantly reduces energy consumption by minimizing heat loss. This forward-thinking approach underlines manufacturers’ commitment to sustainability while reinforcing their position as authoritative providers of cutting-edge glass solutions.

A significant advancement in float flat glass is its integration into smart technology. Smartglass technology, leveraging float flat glass as its foundation, provides dynamic control over sunlight penetration, privacy, and even acts as a digital display medium. This intersection of technology and material science enhances user experience, making environments more adaptive and customizable based on user preferences.

The credibility of float flat glass is not only anchored in its application and innovation but also in its stringent production standards. Renowned manufacturers implement rigorous quality control processes to ensure every sheet of glass meets international safety and performance standards. This dedication to quality fosters trust among consumers and industries, reinforcing the glass's reputation as a reliable and superior product.

In conclusion, the importance of float flat glass extends beyond its physical presence. It's a testament to human ingenuity and the relentless pursuit of integrating form and function. With each innovation and application, it solidifies its place as not merely a product but as a pivotal cornerstone in design and engineering. For those seeking a material that embodies quality, precision, and sustainability, float flat glass remains unparalleled, offering a clear view into the future of construction and design.