Float glass, also known as flat glass, revolutionized the glassmaking industry, shaping the modern architecture of our urban landscapes. With its unique production process and unmatched clarity, float glass has become the cornerstone of modern construction and design, lending itself to applications ranging from architectural facades to intricate interior designs.

The creation of float glass involves a meticulously controlled process where molten glass is poured onto a bed of molten tin, allowing it to spread and form a smooth, flat surface. This method, discovered in the mid-20th century, eliminated the need for grinding and polishing – a testament to innovation in glass manufacturing. Not only does this produce a flawless finish, but it also ensures uniform thickness, which is crucial for structural integrity and optical clarity.

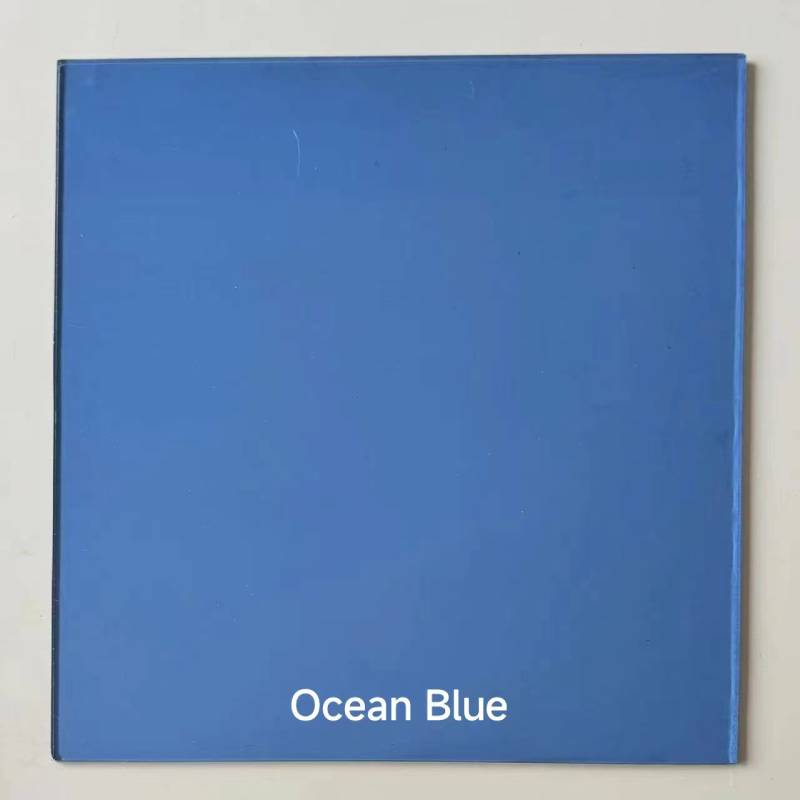

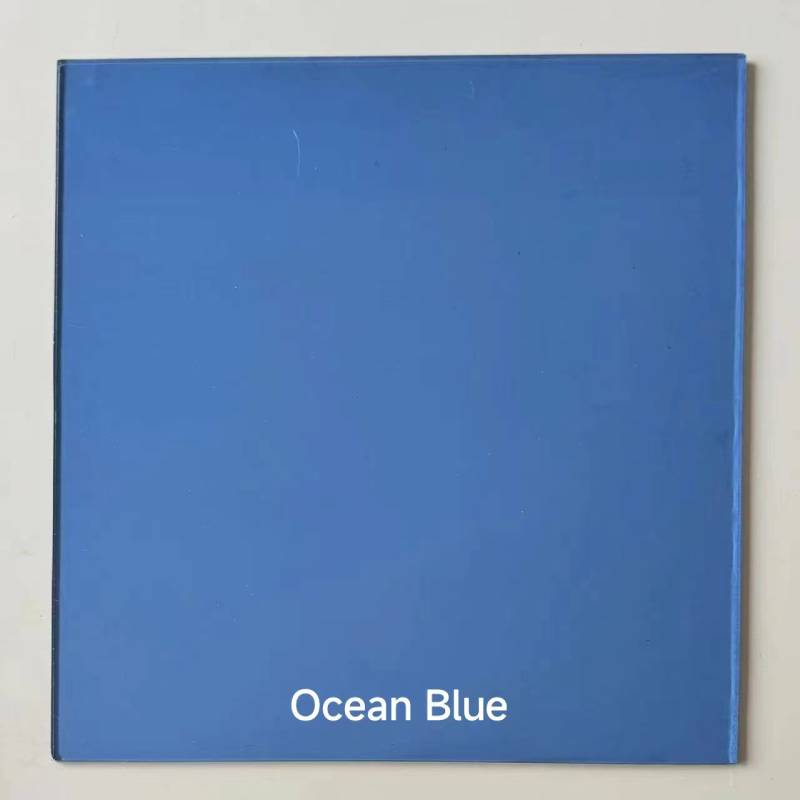

Float glass's versatility makes it an indispensable product in the building and construction sector. Its use in windows underscores its ability to maximize natural light while providing superb optical transparency. As energy efficiency becomes a pivotal concern in modern construction, float glass, with its capacity to support various coatings, plays an essential role in energy conservation. Specialized coatings can transform ordinary float glass into energy-efficient glazing solutions, addressing thermal insulation and solar control needs, thereby reducing the carbon footprint of entire buildings.

In recent years, the drive towards sustainability has propelled innovations within floating glass technology. Manufacturers are now focusing on improving the energy efficiency of the melt process and increasing the use of recycled materials in production. As a result, environmentally conscious architects and builders often prefer float glass as a sustainable choice that doesn't compromise on aesthetics or performance.

float glass

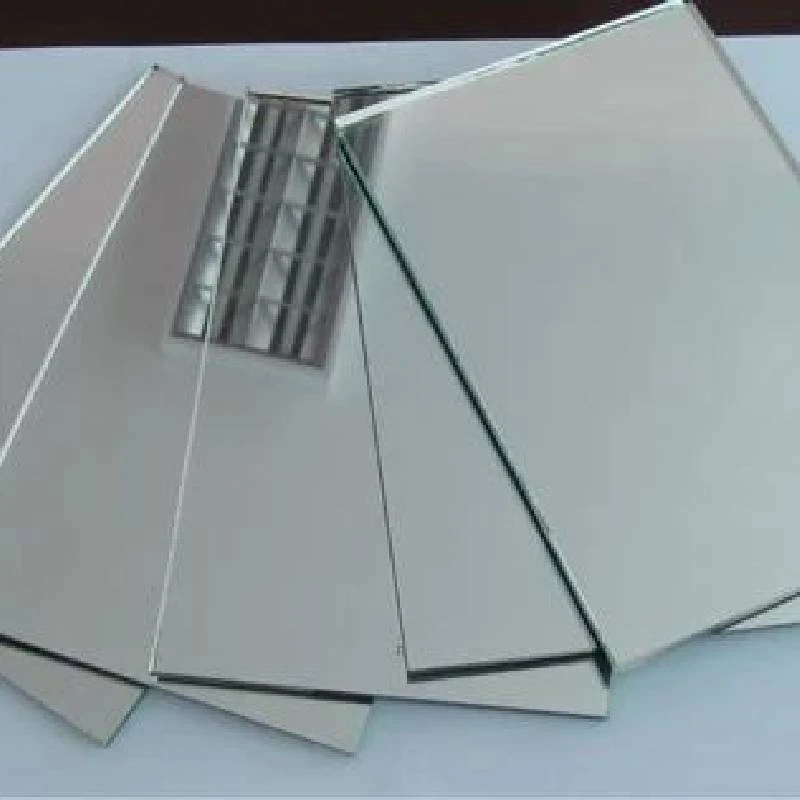

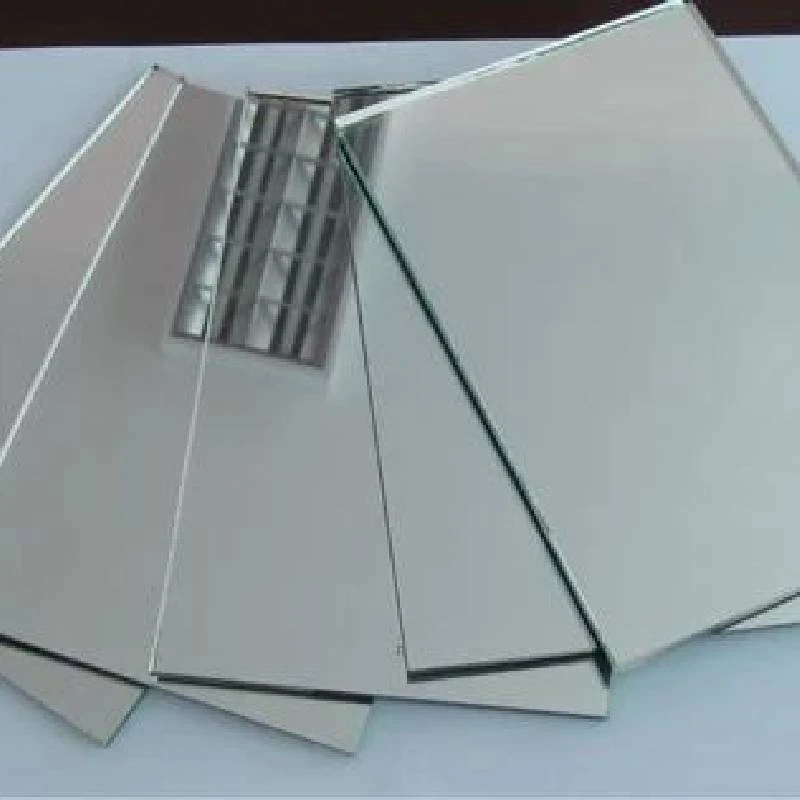

Beyond architecture, float glass finds utility in the creation of mirrors, furniture, and automotive components. Its unique properties allow designers the freedom to imagine and construct with fewer constraints. In the automotive industry, its application ranges from windshield manufacturing to more futuristic uses in HUD systems, where its clarity and minimal distortion remain essential.

When considering float glass suppliers, scrutinizing the credibility and expertise of the manufacturer is critical. Established suppliers often adhere to stringent quality control standards, ensuring that the glass not only meets industry benchmarks but exceeds them in terms of durability, safety, and reliability. An understanding of these standards is vital for making informed decisions, whether for commercial projects or bespoke designs.

The authority of float glass in the industry is supported by decades of research and continual advancement. Entities like the Glass Association of North America (GANA) and other international bodies provide critical oversight, ensuring that float glass products benefit from the latest in safety protocols and technological advancements. Choosing products certified by these authoritative bodies ensures higher trustworthiness and product reliability.

Investing in float glass is as much about understanding its origin and applications as it is about embracing a material that continues to evolve with contemporary needs. Its proven track record combined with future-forward innovations, positions float glass as not just a building material, but a pivotal component of modern design and sustainability efforts.